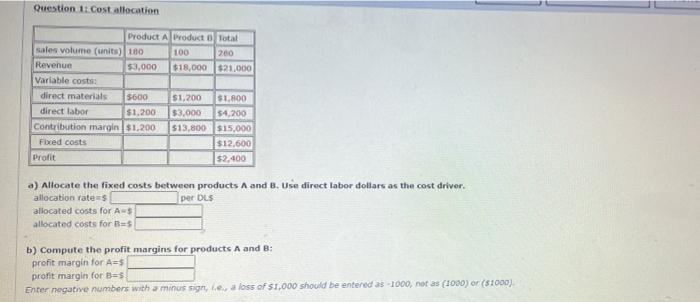

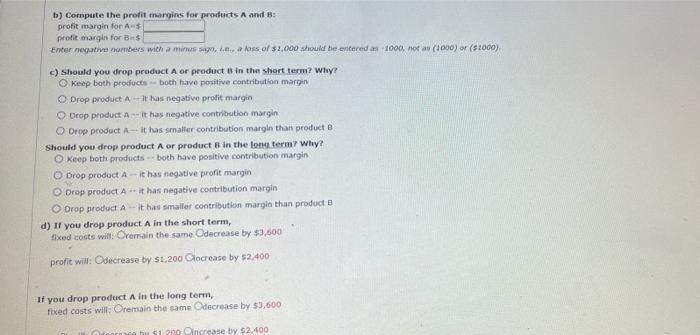

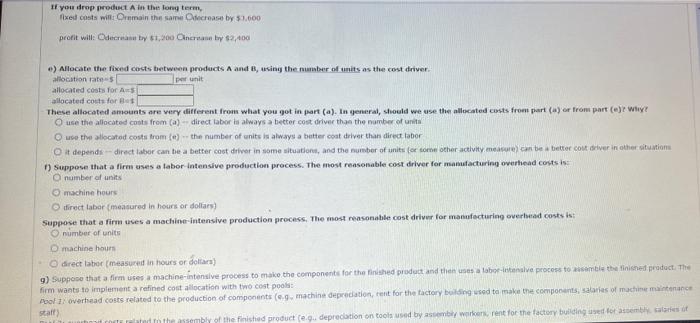

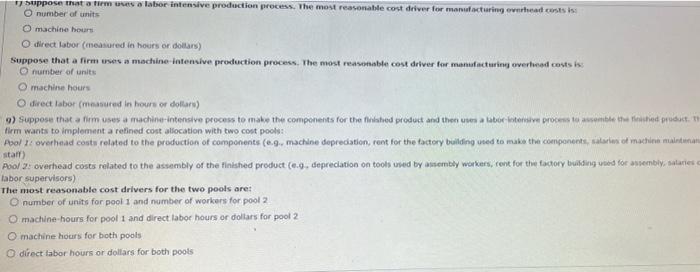

Question 1. Cost allocation Product A Product Total sales volume (units) 180 100 200 Revenue $3,000 618,000 $21.000 Variable costs: direct materials 5600 $1,200 $1,800 direct labor $1.200 $3,000 $4,200 Contribution margin $1,200 513,800 $15,000 Fixed costs $12.600 Profit $2,400 a) Allocate the fixed costs between products A and B. Use direct labor dollars as the cost driver. allocation rates per DLS allocated costs for AS allocated costs for Bus b) Compute the profit margins for products A and B: profit margin for A=$ profit margin for Bas Enter negative numbers with a minus sign, le, a loss of $1,000 should be entered as 1000, notas (1000) or (51000) b) Compute the profit margins for products A and B: profit margin for AS profit margin for $ Enter negative numbers with a minus g.loss of $2,000 should be entered a 1000, notas (1000) or (2000) c) Should you drop product A or product in the short term? Why? Keap both products - both have positive contribution margin Drop product it has negative profit margin Drop product it has negative contribution margin O Drop product A- it has smaller contribution margin than producte Should you drop product A or product in the long term? Why? Keep both products - both have positive contribution margin O Drop product A - it has negative profit margin Drop product Ait has negative contribution margin Drop product A - it has smaller contribution margin than product d) If you drop product A in the short term, fixed costs will remain the same decrease by $3,600 profit will: Odecrease by $1,200 Cincrease by $2,400 If you drop product A In the long term, Fixed costs will: Oremain the same decrease by $3,600 200 increase by $2,400 If you drop product in the long term, fixed costs will remain the same decrease by 52.600 profit will: Odecrease by $1,200 Cincrease by $2,400 e) Allocate the fixed costs between products A and B asing the number of units as the cost driver allocation rates per unit allocated costs for AS allocated costs for These allocated amounts are very different from what you got in part (a). In general, should we use the allocated costs from part(s) or from part (or whiyd use the allocated costs from (a) - direct laboris always a better cost driver than the number of unita Owe the allocated costs from the number of units is always a better coat driver than direct labor O it depends - direct labor can be a better cost driver in some situations, and the number of units for some other activity measure can be better cont driver in other situation 1) Suppose that a firm uses a labor intensive production process. The most reasonable cost driver for manufacturing overhead costs is number of units machine hours direct labor measured in hours or dollars) Suppose that a firm uses a machine intensive production process. The most reasonable cost driver for manufacturing overlad costs i number of units O machine hours O direct labor measured in hours or dolara) 9) Suppose that a firm uses a machine intensive process to make the components for the finished product and then es abe-intensive process to be the finished product. The firm wants to implement a refined cost allocation with two cost pool Pool/ overhead costs related to the production of components (eg machine depreciation, rent for the factory building used to make the components, salaries of machine maintenance stalt and in the assembly of the finished producte..depreciation on tools used by assembly workers.rent for the factory building used for the latest suppose that was a labor intensive production process. The most reasonable cost driver for manufacturing overheads number of units O machine hours O direct labor (measured in hours or dollars) Suppose that a firm uses a machine-intensive production process. The most reasonable cost driver for manufacturing overweed costs O number of units machine hours O direct labor (measured in hours or dollar) 9) Suppose that a firm uses a machine-intensive process to make the components for the finished product and then una labor intensive process to emble the throned product. 1 firm wants to implement a refined cost allocation with two cost pools Pool overhead costs related to the production of components (eg machine depreciation rent for the factory building used to make the components, all of machine man stall Pool 2 overhead costs related to the assembly of the finished product (0.9. depreciation on tools used by membly workers, rent for the factory building good for membly, salaries labor supervisors) The most reasonable cost drivers for the two pools are number of units for pool 1 and number of workers for pool 2 O machine-hours for pool 1 and direct labor hours or dollars for pool 2 O machine hours for both pools O direct labor hours or dollars for both pools