Answered step by step

Verified Expert Solution

Question

1 Approved Answer

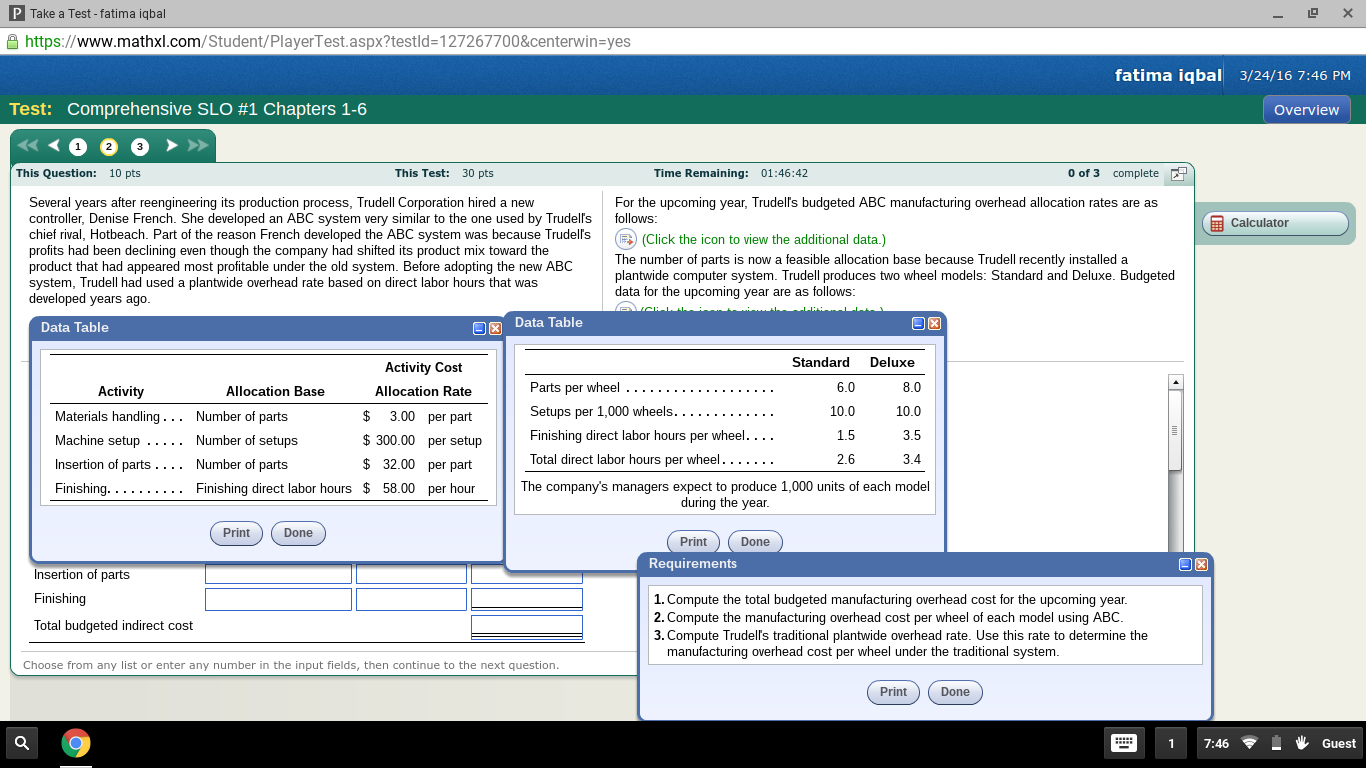

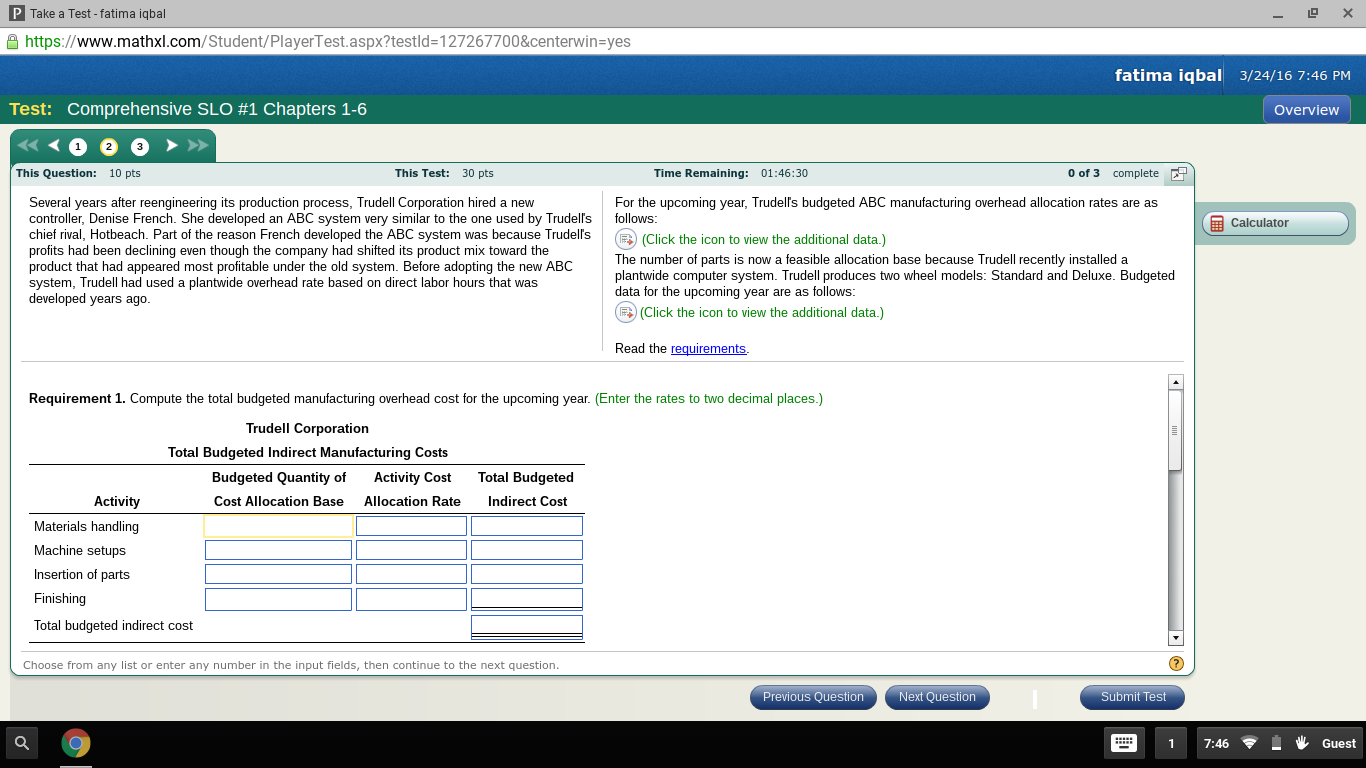

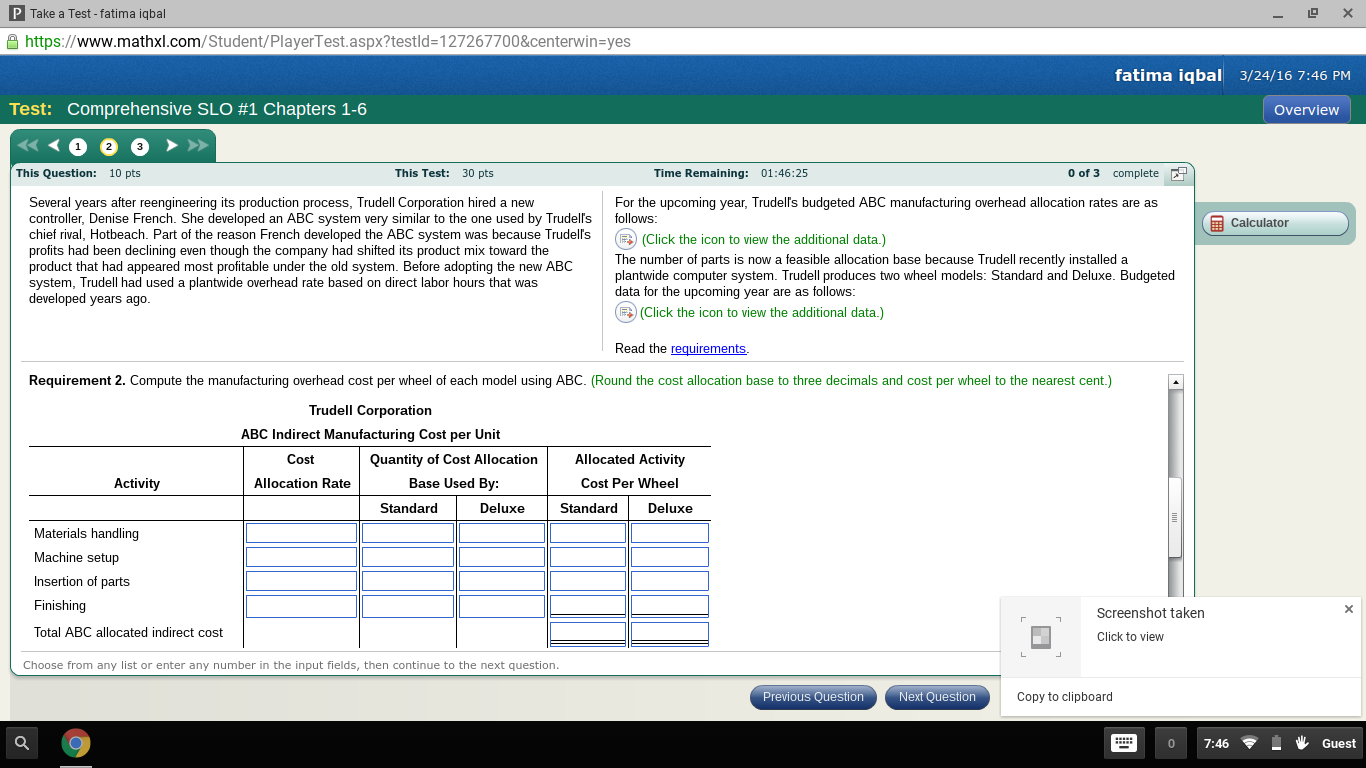

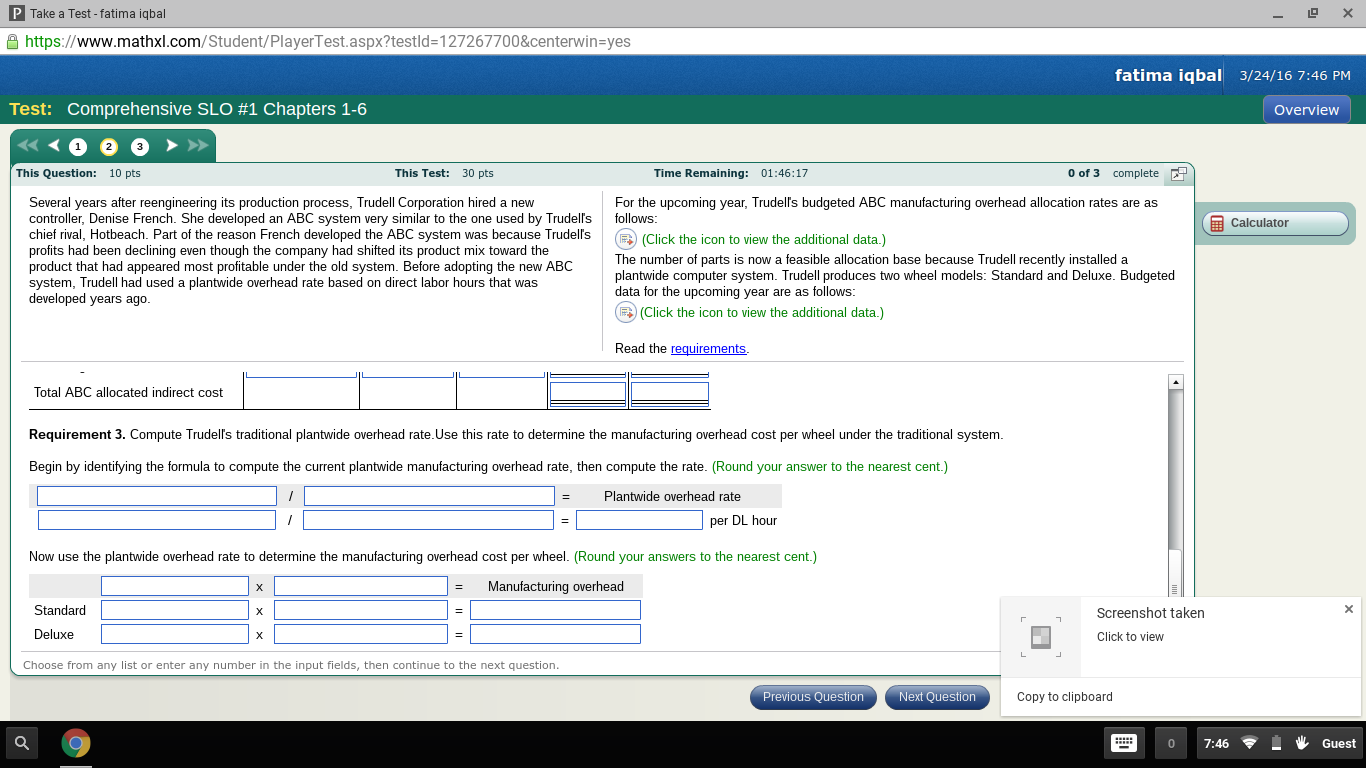

question clear. thank you :) P Take a Test-fatima iqbal P Take a Test -fatima iqba https://www.mathxl.com/Student/PlayerTest.aspx?testld-127267700¢erwin-yes fatima iqbal 3/24/16 7:46 PM Test: Comprehensive SLO

question clear. thank you :)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started