Answered step by step

Verified Expert Solution

Question

1 Approved Answer

QUESTIONS: 1) For the month of August, calculate the following variances (assuming the standard labor rate is $0.92 per hour): a) Material usage variance for

QUESTIONS:

1) For the month of August, calculate the following variances (assuming the standard labor rate is $0.92 per hour):

a) Material usage variance for flash memories

b) Labor usage (efficiency) variance

2) What are some strategies or decisions that Wentao Chen should consider when trying to solve the problems with the Apple iPhone 4 contract in the next nine months?

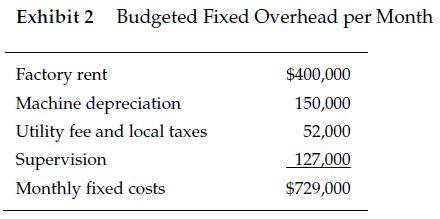

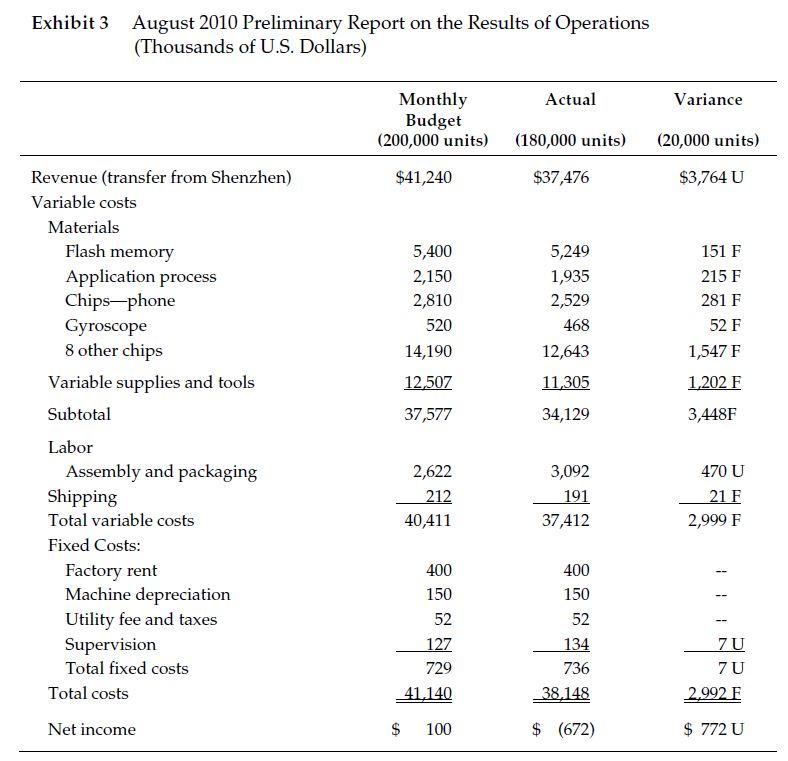

In August 2010, Wentao Chen, manager of Danshui Plant No 2 in southern China, was anxious. The plant was in the third month of a 12-month contract to assemble the iPhone 4. The contract called for the plant to assemble 2.4 million phones in the period between June 1, 2010 and May 31,2011 , but now in the third month of the contract production was only 180,000 units per month. Chen called Jianye Ma, the plant controller, to request a summary of monthly operations for August as soon after the end of the month as possible. Danshui was a contract manufacturer that assembled electronic products for companies wishing to save labor costs by locating in the Southern China where semiskilled labor was available for less than one| dollar an hour. Manufacturers like Danshui assembled parts in large plants using assembly line techniques according to specification of the international companies that contracted with them for assembly and final testing. The largest contract manufacturer in China was Foxconn, a division of the Hon Hai Group of Taiwan, with more than 800,000 workers in China alone and contracts to supply Apple, Dell and HP among others. In expectation of high demand for the iPhone 4, Apple had contracted with Danshui to assemble iPhone in Plant No 2, which had been assembling computer hard drives on a contract that was fulfilled at the end of May 2010. Although the assembly of hard drives was different than assembly of iPhones, Danshui was confident that its workers would adapt to the new assembly tasks and that it could hire and train the additional workers as needed. Chen's job was to get Plant No 2 up to speed to fulfill the Apple contract and earn a profit for Danshui's parent company, located in Hong Kong, China. Danshui Pant No 2 was a profit center that was credited for each iPhone produced and shipped, and charged for parts, labor, overhead and shipping. Because the contract was for a year, an annual budget was established soon after the iPhone contract was signed. This budget was divided by 12 to establish equal monthly budgets to which actual revenues and expenses could be compared. All budgeting and monthly reporting was done in US dollars. As the plant manager, Wentao Chen was responsible for control of all costs in his plant. Materials labor, and overhead were his responsibility. This was done to provide incentive to control all costs whether caused by use waste, damage, theft or inefficiencies. The Apple iPhone 4 The iPhone 4 contained more than 100 components manufactured in plants located in Europe, Asia and the US. For examples, Samsung supplied flash memories and application processors, and Infineon (a German chip maker) supplied chips that send and receive phone calls and data. A gyroscope, new to iPhone 4, came from STMicroelectronics, based in Geneva, and a touch-screen module came from Taiwan. Contract manufacturers assembled these parts in assembly line plants that required each worker to focus on one or more tasks in a short period of time as each phone moved along an assembly line toward completion. Estimates of the material cost of each iPhone were around $180, assembly labor around 7% of total cost and Apple's profit margins about 60% of the selling price to customers. (See Exhibits 1 and 2 for estimated standard costs and overhead budgets for the Danshui Plant No 2) The assembly process at Danshui Plant No 2 was almost entirely based on handwork by workers. There individuals during the five days required for assembly. Apple released the iPhone 4 on June 24,2010 and more than 1.7 million units were sold in the first three days it was available. It was the most successful product launch in Apple history. Apple fanatics around the world waited in long lines to get their hands on the new phone. The August Report On September 2, Chen arrived at his office and found a report on August operations. (See Exhibit 3). The controller, Jianye Ma, had attached a note which Chen read with interest. To: Wentao Chen From Jianye Ma and Bingqian Li Date: September 1,2010 Per your request we have compiled a preliminary report on August operations. At first glance, revenue was below budget, material usage seems good, and labor costs were above budget. In terms of plant profit, our budget was $100,000 but we actually had a loss of $672,00. The main reason for the shortfall may be that we have been unable to produce 200,000 iPhone 4 units in any of the three months we have been working on this contract. Our major obstacle is hiring enough qualified labor to get production up to 200,000 uniters per month. We cannot find people to hire, even though we have raised our factory wages by almost 30% since July. (A friend at Foxconn in Shenzhen told Li that they raised their starting pay by 35% since March, and they are building new plants elsewhere where unemployment is high.) In addition, we continue to have trouble with the Samsung flash memory installation. Unless these are handled very carefully, they can be damaged by heat during installation. One thousand flash memories were damaged in August and had to be replaced after inspection. Samsung is aware of this problem and has begun to install a shield to prevent some of the damage; however, as a result, Samsung raised the price of each unit $2.00 starting in mid-June. Fortunately, Apple raised our revenue recovery by an equal amount, so this should be neutral. We apparently had a favorable variance on flash memories and other parts. Li is uncomfortable with this report. She feels we should prepare a new budget showing what we would have spent using standard costs and a production volume of 180,000 units. She says that the current report (Exhibit 3) distorts how we did, and that until we prepare a "flexible budget" to compare our actual performance to that budget we run the risk of misinterpreting our performance. It will take Li a couple of days to prepare and evaluate a flexible budget because she is working on a tax report that is due September 7 . I will talk with you next week once we receive the flexible budget from Li. Exhibit 1 Standard Variable Costs for iPhone 4 (U.S. Dollars) Exhibit 2 Budgeted Fixed Overhead per Month Exhibit 3 August 2010 Preliminary Report on the Results of Operations In August 2010, Wentao Chen, manager of Danshui Plant No 2 in southern China, was anxious. The plant was in the third month of a 12-month contract to assemble the iPhone 4. The contract called for the plant to assemble 2.4 million phones in the period between June 1, 2010 and May 31,2011 , but now in the third month of the contract production was only 180,000 units per month. Chen called Jianye Ma, the plant controller, to request a summary of monthly operations for August as soon after the end of the month as possible. Danshui was a contract manufacturer that assembled electronic products for companies wishing to save labor costs by locating in the Southern China where semiskilled labor was available for less than one| dollar an hour. Manufacturers like Danshui assembled parts in large plants using assembly line techniques according to specification of the international companies that contracted with them for assembly and final testing. The largest contract manufacturer in China was Foxconn, a division of the Hon Hai Group of Taiwan, with more than 800,000 workers in China alone and contracts to supply Apple, Dell and HP among others. In expectation of high demand for the iPhone 4, Apple had contracted with Danshui to assemble iPhone in Plant No 2, which had been assembling computer hard drives on a contract that was fulfilled at the end of May 2010. Although the assembly of hard drives was different than assembly of iPhones, Danshui was confident that its workers would adapt to the new assembly tasks and that it could hire and train the additional workers as needed. Chen's job was to get Plant No 2 up to speed to fulfill the Apple contract and earn a profit for Danshui's parent company, located in Hong Kong, China. Danshui Pant No 2 was a profit center that was credited for each iPhone produced and shipped, and charged for parts, labor, overhead and shipping. Because the contract was for a year, an annual budget was established soon after the iPhone contract was signed. This budget was divided by 12 to establish equal monthly budgets to which actual revenues and expenses could be compared. All budgeting and monthly reporting was done in US dollars. As the plant manager, Wentao Chen was responsible for control of all costs in his plant. Materials labor, and overhead were his responsibility. This was done to provide incentive to control all costs whether caused by use waste, damage, theft or inefficiencies. The Apple iPhone 4 The iPhone 4 contained more than 100 components manufactured in plants located in Europe, Asia and the US. For examples, Samsung supplied flash memories and application processors, and Infineon (a German chip maker) supplied chips that send and receive phone calls and data. A gyroscope, new to iPhone 4, came from STMicroelectronics, based in Geneva, and a touch-screen module came from Taiwan. Contract manufacturers assembled these parts in assembly line plants that required each worker to focus on one or more tasks in a short period of time as each phone moved along an assembly line toward completion. Estimates of the material cost of each iPhone were around $180, assembly labor around 7% of total cost and Apple's profit margins about 60% of the selling price to customers. (See Exhibits 1 and 2 for estimated standard costs and overhead budgets for the Danshui Plant No 2) The assembly process at Danshui Plant No 2 was almost entirely based on handwork by workers. There individuals during the five days required for assembly. Apple released the iPhone 4 on June 24,2010 and more than 1.7 million units were sold in the first three days it was available. It was the most successful product launch in Apple history. Apple fanatics around the world waited in long lines to get their hands on the new phone. The August Report On September 2, Chen arrived at his office and found a report on August operations. (See Exhibit 3). The controller, Jianye Ma, had attached a note which Chen read with interest. To: Wentao Chen From Jianye Ma and Bingqian Li Date: September 1,2010 Per your request we have compiled a preliminary report on August operations. At first glance, revenue was below budget, material usage seems good, and labor costs were above budget. In terms of plant profit, our budget was $100,000 but we actually had a loss of $672,00. The main reason for the shortfall may be that we have been unable to produce 200,000 iPhone 4 units in any of the three months we have been working on this contract. Our major obstacle is hiring enough qualified labor to get production up to 200,000 uniters per month. We cannot find people to hire, even though we have raised our factory wages by almost 30% since July. (A friend at Foxconn in Shenzhen told Li that they raised their starting pay by 35% since March, and they are building new plants elsewhere where unemployment is high.) In addition, we continue to have trouble with the Samsung flash memory installation. Unless these are handled very carefully, they can be damaged by heat during installation. One thousand flash memories were damaged in August and had to be replaced after inspection. Samsung is aware of this problem and has begun to install a shield to prevent some of the damage; however, as a result, Samsung raised the price of each unit $2.00 starting in mid-June. Fortunately, Apple raised our revenue recovery by an equal amount, so this should be neutral. We apparently had a favorable variance on flash memories and other parts. Li is uncomfortable with this report. She feels we should prepare a new budget showing what we would have spent using standard costs and a production volume of 180,000 units. She says that the current report (Exhibit 3) distorts how we did, and that until we prepare a "flexible budget" to compare our actual performance to that budget we run the risk of misinterpreting our performance. It will take Li a couple of days to prepare and evaluate a flexible budget because she is working on a tax report that is due September 7 . I will talk with you next week once we receive the flexible budget from Li. Exhibit 1 Standard Variable Costs for iPhone 4 (U.S. Dollars) Exhibit 2 Budgeted Fixed Overhead per Month Exhibit 3 August 2010 Preliminary Report on the Results of OperationsStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started