Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Questions 1-3 please! (: Problem to solve. The operations management team at IT has the following questions: 1. What is the maximum theoretical capacity, in

Questions 1-3 please! (:

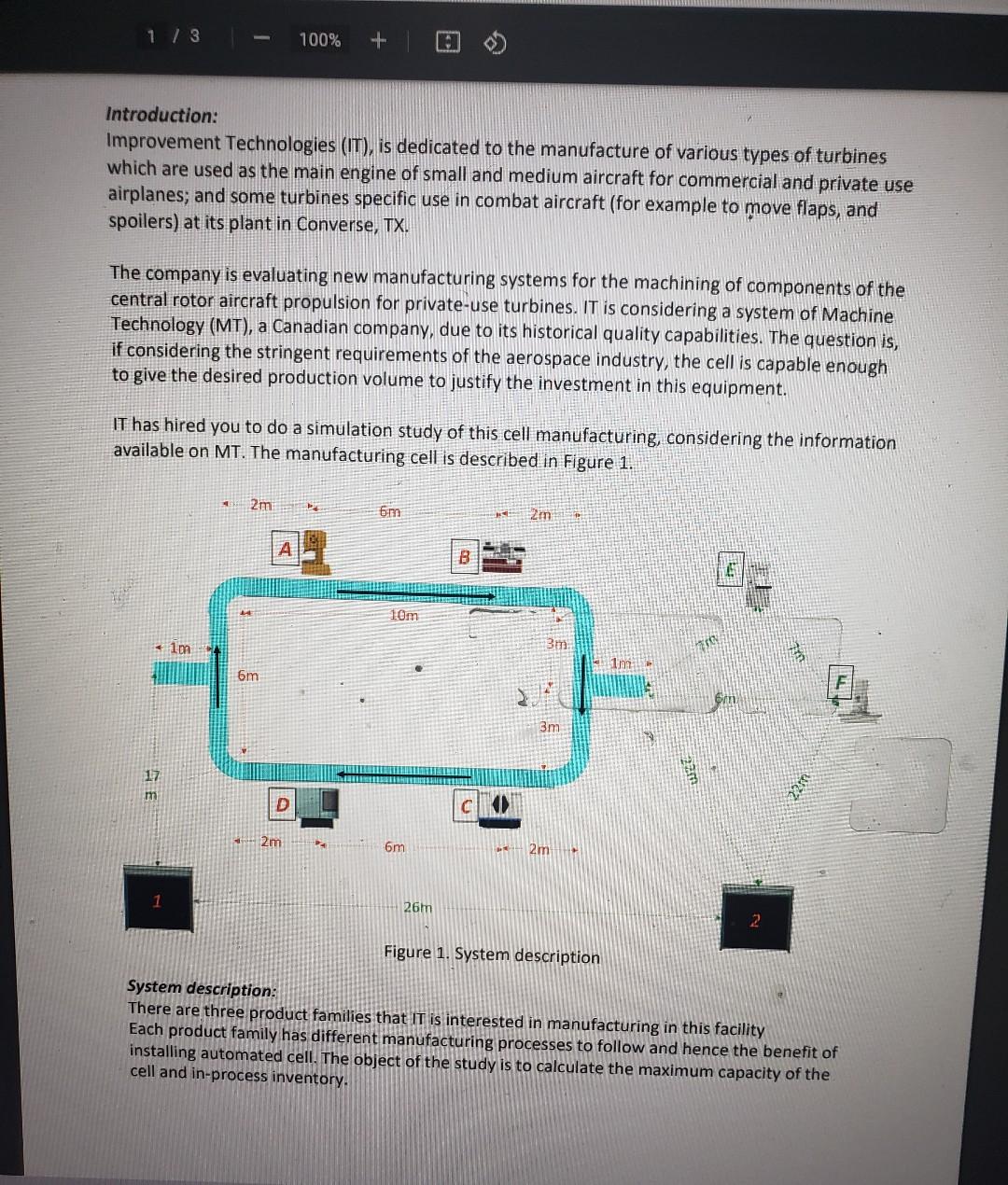

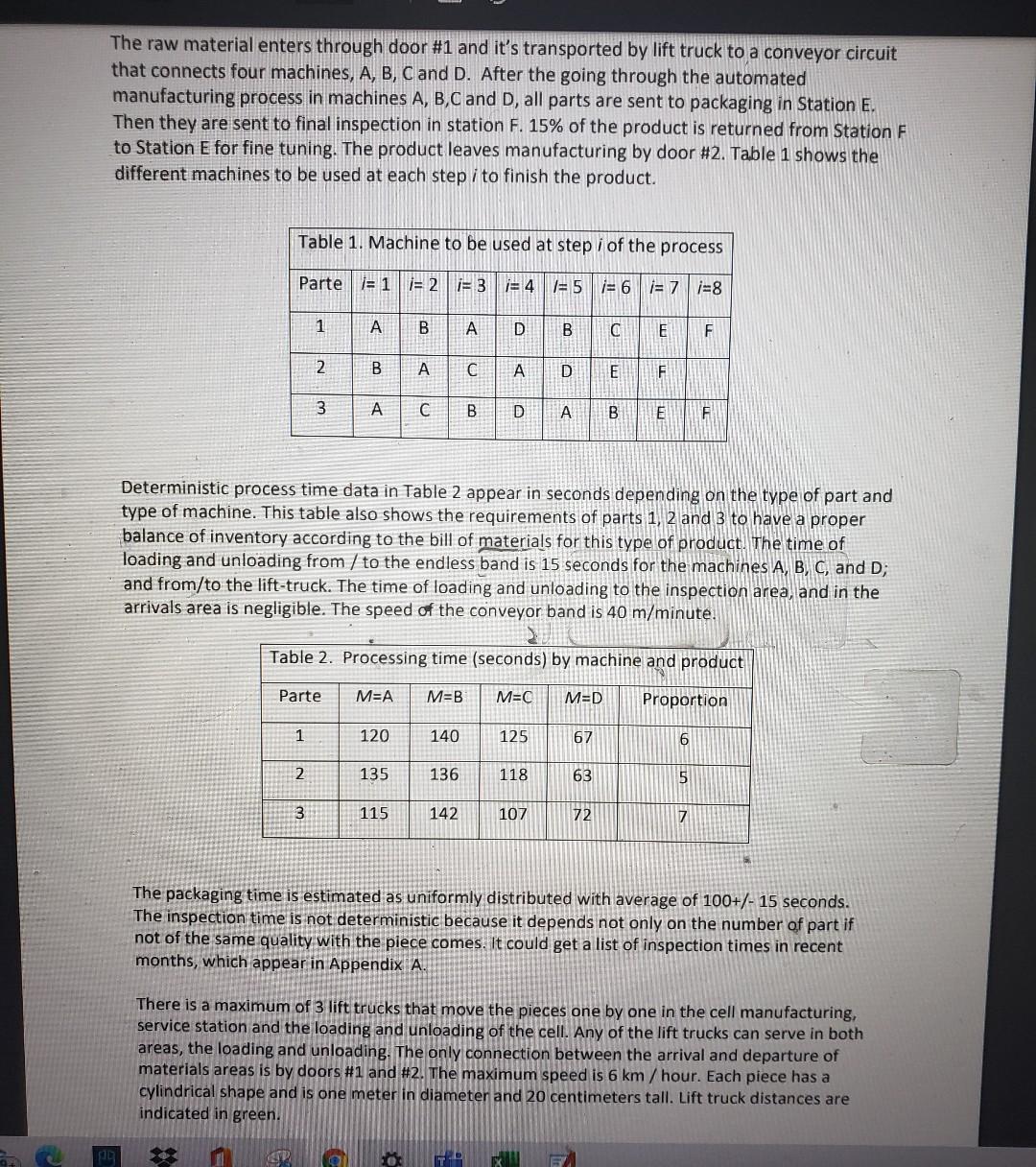

Problem to solve. The operations management team at IT has the following questions: 1. What is the maximum theoretical capacity, in units per hour that the system will? 2. If the bottleneck is used 100%, theoretically what percentage of utilization would the other Imachines have? (Questions 1 and 2 and 3 should be calculated before the simulation), 3. What is the utilization of each machine, including inspection when the bottleneck utilization is 85%? 1 / 3 100% + + Introduction: Improvement Technologies (IT), is dedicated to the manufacture of various types of turbines which are used as the main engine of small and medium aircraft for commercial and private use airplanes; and some turbines specific use in combat aircraft (for example to move flaps, and spoilers) at its plant in Converse, TX. The company is evaluating new manufacturing systems for the machining of components of the central rotor aircraft propulsion for private-use turbines. It is considering a system of Machine Technology (MT), a Canadian company, due to its historical quality capabilities. The question is, if considering the stringent requirements of the aerospace industry, the cell is capable enough to give the desired production volume to justify the investment in this equipment. IT has hired you to do a simulation study of this cell manufacturing, considering the information available on MT. The manufacturing cell is described in Figure 1. 2m 6m 2m B 10m + im 3mm Ini 3m 22 17 m 226 D 2m m 2min 26m Figure 1. System description System description: There are three product families that it is interested in manufacturing in this facility Each product family has different manufacturing processes to follow and hence the benefit of installing automated cell. The object of the study is to calculate the maximum capacity of the cell and in-process inventory. The raw material enters through door #1 and it's transported by lift truck to a conveyor circuit that connects four machines, A, B, C and D. After the going through the automated manufacturing process in machines A, B,C and D, all parts are sent to packaging in Station E. Then they are sent to final inspection in station F. 15% of the product is returned from Station F to Station E for fine tuning. The product leaves manufacturing by door #2. Table 1 shows the different machines to be used at each step i to finish the product. Table 1. Machine to be used at step i of the process Parte = 1 = 2 = 3 = 4 = 5 = 6 = 7 i=8 1 D B. A . D B E F C 2 B A A D ml E F 3 . A B . D A B TI E F Deterministic process time data in Table 2 appear in seconds depending on the type of part and type of machine. This table also shows the requirements of parts 1, 2 and 3 to have a proper balance of inventory according to the bill of materials for this type of product. The time of loading and unloading from / to the endless band is 15 seconds for the machines A, B, C, and D; and from/to the lift-truck. The time of loading and unloading to the inspection area, and in the arrivals area is negligible. The speed of the conveyor band is 40 m/minute. Table 2. Processing time (seconds) by machine and product Parte MEA M=B MEC MED Proportion 1 120 140 125 67 6 2 135 136 118 63 5 3 115 142 107 72 7 The packaging time is estimated as uniformly distributed with average of 100+/- 15 seconds. The inspection time is not deterministic because it depends not only on the number of part if not of the same quality with the piece comes. It could get a list of inspection times in recent months, which appear in Appendix A. There is a maximum of 3 lift trucks that move the pieces one by one in the cell manufacturing, service station and the loading and unloading of the cell. Any of the lift trucks can serve in both areas, the loading and unloading. The only connection between the arrival and departure of materials areas is by doors #1 and #2. The maximum speed is 6 km/hour. Each piece has a cylindrical shape and is one meter in diameter and 20 centimeters tall. Lift truck distances are indicated in green. Problem to solve. The operations management team at IT has the following questions: 1. What is the maximum theoretical capacity, in units per hour that the system will? 2. If the bottleneck is used 100%, theoretically what percentage of utilization would the other Imachines have? (Questions 1 and 2 and 3 should be calculated before the simulation), 3. What is the utilization of each machine, including inspection when the bottleneck utilization is 85%? 1 / 3 100% + + Introduction: Improvement Technologies (IT), is dedicated to the manufacture of various types of turbines which are used as the main engine of small and medium aircraft for commercial and private use airplanes; and some turbines specific use in combat aircraft (for example to move flaps, and spoilers) at its plant in Converse, TX. The company is evaluating new manufacturing systems for the machining of components of the central rotor aircraft propulsion for private-use turbines. It is considering a system of Machine Technology (MT), a Canadian company, due to its historical quality capabilities. The question is, if considering the stringent requirements of the aerospace industry, the cell is capable enough to give the desired production volume to justify the investment in this equipment. IT has hired you to do a simulation study of this cell manufacturing, considering the information available on MT. The manufacturing cell is described in Figure 1. 2m 6m 2m B 10m + im 3mm Ini 3m 22 17 m 226 D 2m m 2min 26m Figure 1. System description System description: There are three product families that it is interested in manufacturing in this facility Each product family has different manufacturing processes to follow and hence the benefit of installing automated cell. The object of the study is to calculate the maximum capacity of the cell and in-process inventory. The raw material enters through door #1 and it's transported by lift truck to a conveyor circuit that connects four machines, A, B, C and D. After the going through the automated manufacturing process in machines A, B,C and D, all parts are sent to packaging in Station E. Then they are sent to final inspection in station F. 15% of the product is returned from Station F to Station E for fine tuning. The product leaves manufacturing by door #2. Table 1 shows the different machines to be used at each step i to finish the product. Table 1. Machine to be used at step i of the process Parte = 1 = 2 = 3 = 4 = 5 = 6 = 7 i=8 1 D B. A . D B E F C 2 B A A D ml E F 3 . A B . D A B TI E F Deterministic process time data in Table 2 appear in seconds depending on the type of part and type of machine. This table also shows the requirements of parts 1, 2 and 3 to have a proper balance of inventory according to the bill of materials for this type of product. The time of loading and unloading from / to the endless band is 15 seconds for the machines A, B, C, and D; and from/to the lift-truck. The time of loading and unloading to the inspection area, and in the arrivals area is negligible. The speed of the conveyor band is 40 m/minute. Table 2. Processing time (seconds) by machine and product Parte MEA M=B MEC MED Proportion 1 120 140 125 67 6 2 135 136 118 63 5 3 115 142 107 72 7 The packaging time is estimated as uniformly distributed with average of 100+/- 15 seconds. The inspection time is not deterministic because it depends not only on the number of part if not of the same quality with the piece comes. It could get a list of inspection times in recent months, which appear in Appendix A. There is a maximum of 3 lift trucks that move the pieces one by one in the cell manufacturing, service station and the loading and unloading of the cell. Any of the lift trucks can serve in both areas, the loading and unloading. The only connection between the arrival and departure of materials areas is by doors #1 and #2. The maximum speed is 6 km/hour. Each piece has a cylindrical shape and is one meter in diameter and 20 centimeters tall. Lift truck distances are indicated in greenStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started