Question: Read the case study thoughtfully and answer the following questions: Discuss the different quality term as presented by the author. Which one of these terms

Read the case study thoughtfully and answer the following questions:

- Discuss the different quality term as presented by the author. Which one of these terms is more practical from your point of view? ( 250 300 words)

- Describe the printing company` production process current state. Which one of the current issues listed is more critical and why? ( 250 300 words )

- Do you think the proposed actions for improvements are efficient? Explain. ( 200 300 words )

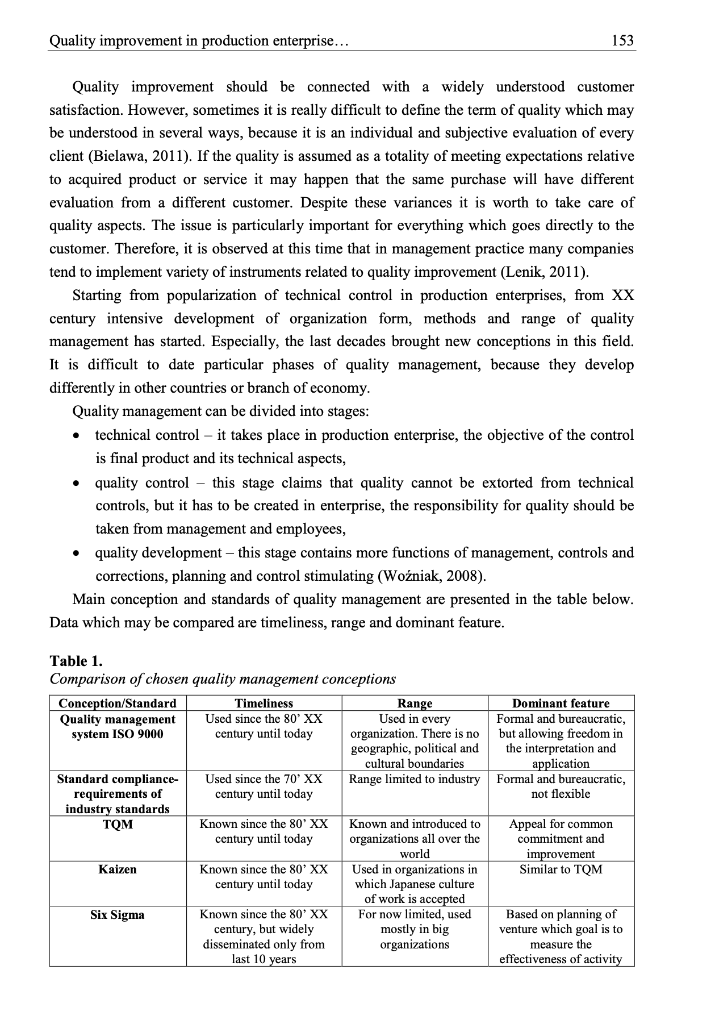

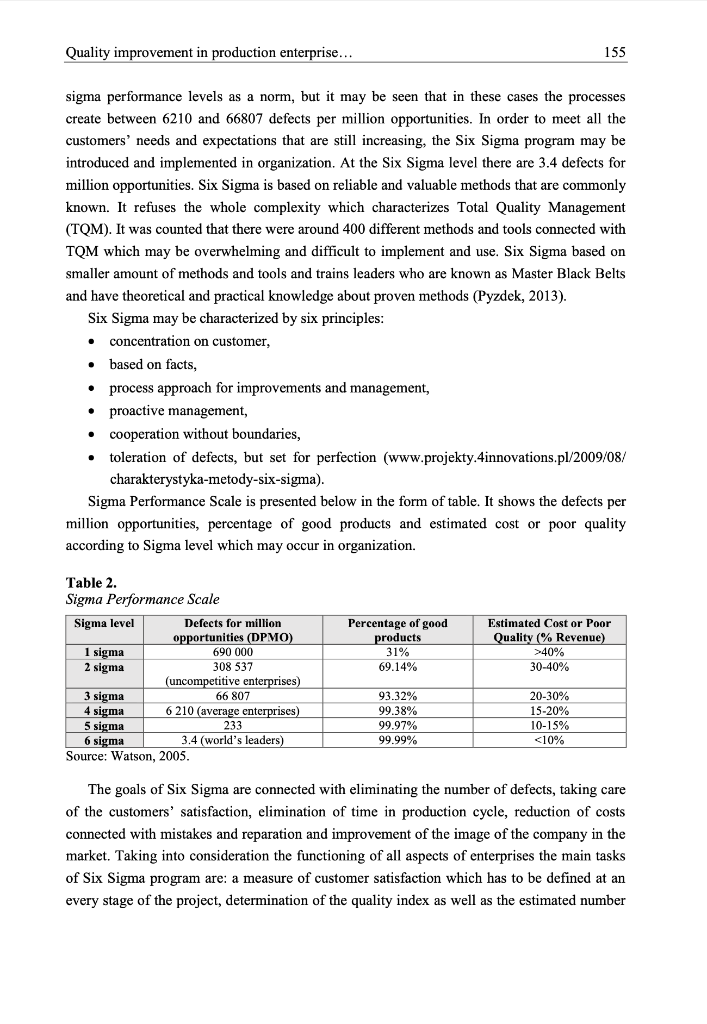

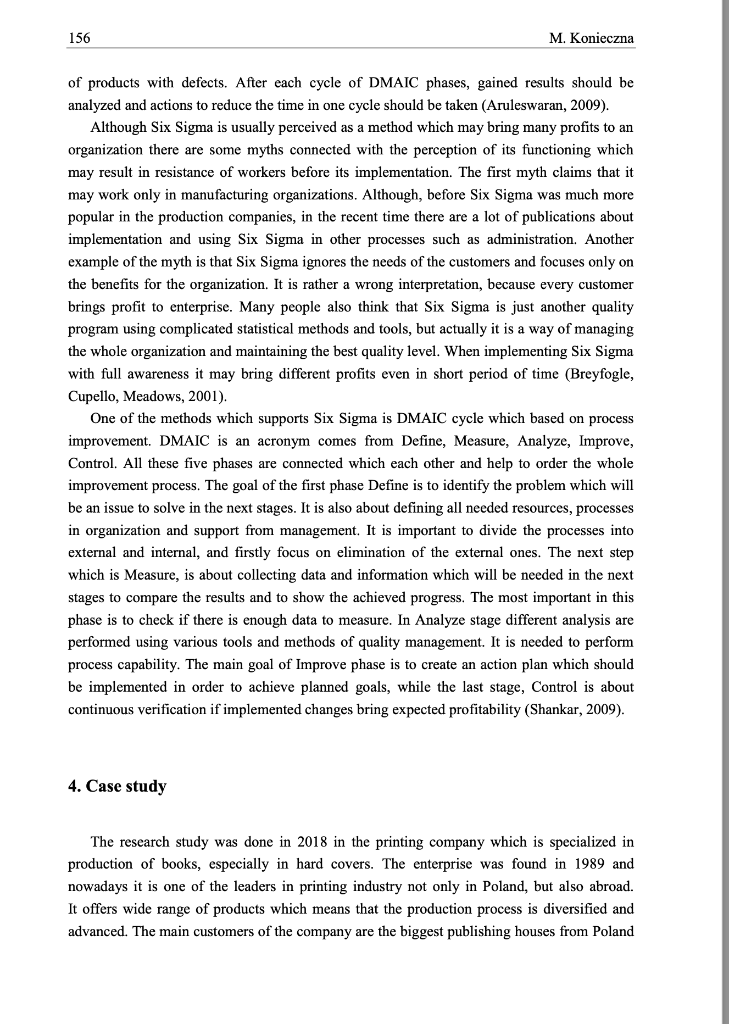

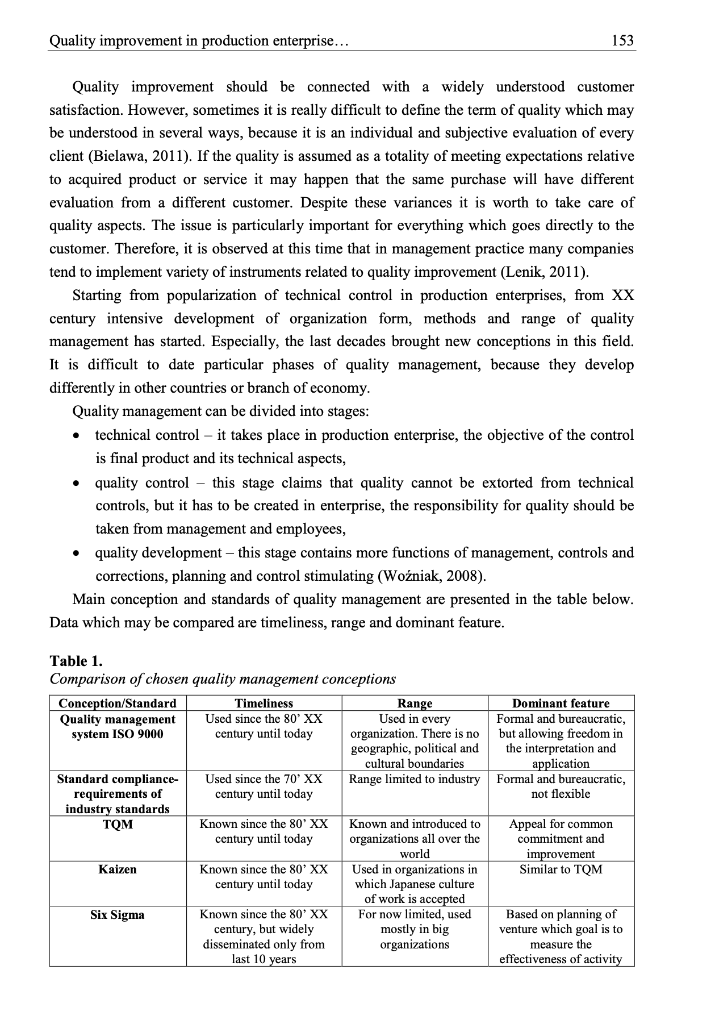

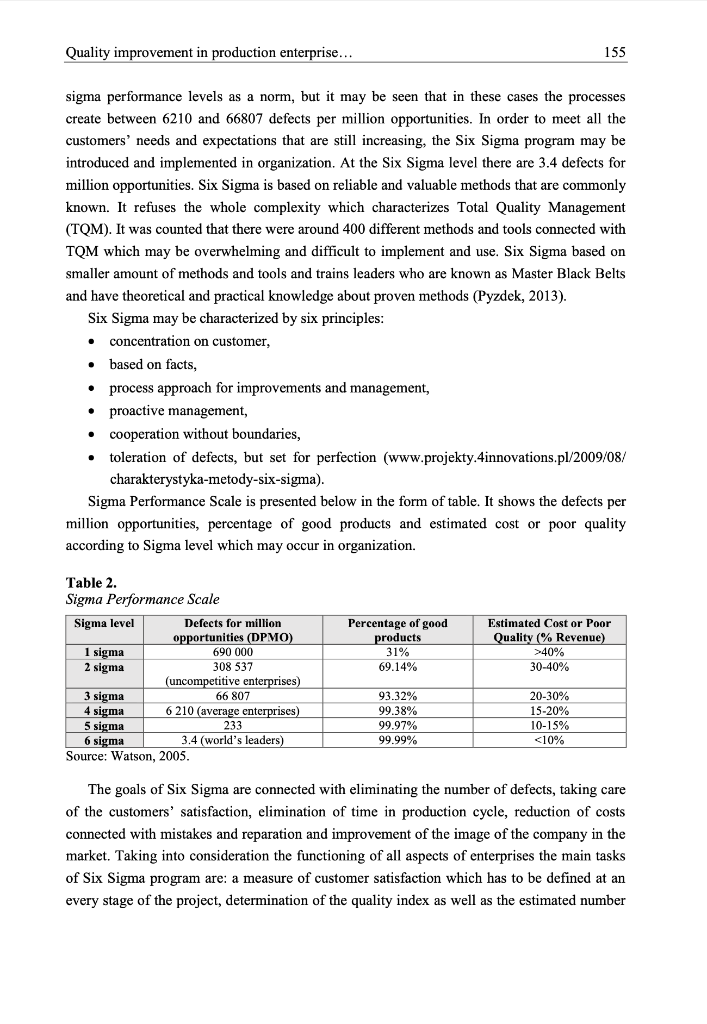

QUALITY IMPROVEMENT IN PRODUCTION ENTERPRISE. CASE STUDY Monika KONIECZNA Politechnika Poznaska, Wydzia Inynierii Zarzdzania; monika.t.konieczna@doctorate.put.poznan.pl Abstract. The main objective of this paper is to determine the meaning of quality in present enterprise as well as its influence for the continuous development. There is shown comparison of chosen quality management conceptions as well as description of one of them, Six Sigma which is an innovative approach to quality. Presented case study was developed in a printing company specialized in production of books in hard covers. This study presents the proposition of improvement to increase the effectiveness of the production process. Keywords: quality management, process improvement. 1. Introduction In recent years, it may be noticed a huge pressure on enterprises to maintain and develop high quality level in organization, and at the same time to decrease ineffectiveness and reduce the number of errors. In order to gain and keep customers, organizations have to compete with each other. Sometimes it may be difficult, because present enterprises show very good adaptation to upcoming changes. It is essential to understand that the most important in quality management is to satisfy customers' needs, because the customers are the factor which drive the market economy nowadays. There are many different conceptions, methods and tools that may be used to maintain the good quality level and help in continuous development in the company. One example of well-known conception is Six Sigma which is an innovative method introduced in Motorola by Bob Galvin and Bill Smith in the middle of the eighties. The article focuses on presenting the term of quality and emphasize its role in continuous development in production enterprise. It also shows differences between conceptions of quality management and describe of them in details. Knowing all main conceptions, methods and tools the company can freely decide which is adequate to its brand and activities and which to use in specific situations. Presented case study shows the bottleneck which appears during production process in one of the printing company. There is shown the whole 2. Quality improvement . . There are many different definitions of quality which can be found in literature (Sowiski, 1996). Generally, quality is defined as the sum of characteristics of a product or service which gives the opportunity to meet the customer's needs (Rogoziski, 2000). This definition can be completed by the definition of quality management, as a continuous improvement of everything which is performed in the organization in aspects of quality using well-known methods and with the participation of all employees. According to ISO norm 9000, quality is degree to which a set of inherent characteristics fulfils requirement (PN-EN ISO 9000:2006 - polish version). The evolution of the term quality may be presented as follows: Quality is efficiency in use - J.M. Juran, 1970, Quality meets customers' needs - T. Ishikawa, 1980, Quality is something when missing means loss for everybody - G. Taguchi, 1980, Quality means zero defects - P.B. Crosby, 1985 (Rczka, 1993). Nowadays, it may be seen that quality is one of the basic factors which decides about company's competitiveness. Quickly changes environment requires from enterprises easily reacting for them. The company is forced to search for new conceptions and methods of development. Contemporary environment is characterized by process globalization, shortening the life-cycle of products and technology. Scientific and technological development, increased level of education, easy migration of all resources, high distribution of technology and information, are the chances for organization to achieve better position in the market and being more competitive (ukasiski, 2013). High-quality products and services give the company competitive advantage in domestic and international market. Good quality increases productivity, while reducing costs, but what is the most important, it creates satisfied customers who are more willing to buy the products again and will also recommend the company to other buyers. When mass production has started, there was a need to introduce quality control to the process and create separate quality departments. During 1950' W. Edwards Deming and Joseph Juran were invited to Japan to help the companies in quality management. They strongly believed in importance of quality and using statistical tools in order to improve quality. Nowadays, everyone may learn from the Japanese that it is impossible not to pay attention to quality and that taking care of quality issues is the responsibility of every employee in organization (Evans, 1992). Quality improvement in production enterprise... 153 Quality improvement should be connected with a widely understood customer satisfaction. However, sometimes it is really difficult to define the term of quality which may be understood in several ways, because it is an individual and subjective evaluation of every client (Bielawa, 2011). If the quality is assumed as a totality of meeting expectations relative to acquired product or service it may happen that the same purchase will have different evaluation from a different customer. Despite these variances it is worth to take care of quality aspects. The issue is particularly important for everything which goes directly to the customer. Therefore, it is observed at this time that in management practice many companies tend to implement variety of instruments related to quality improvement (Lenik, 2011). Starting from popularization of technical control in production enterprises, from XX century intensive development of organization form, methods and range of quality management has started. Especially, the last decades brought new conceptions in this field. It is difficult to date particular phases of quality management, because they develop differently in other countries or branch of economy. Quality management can be divided into stages: technical control - it takes place in production enterprise, the objective of the control is final product and its technical aspects, quality control this stage claims that quality cannot be extorted from technical controls, but it has to be created in enterprise, the responsibility for quality should be taken from management and employees, quality development this stage contains more functions of management, controls and corrections, planning and control stimulating (Woniak, 2008). Main conception and standards of quality management are presented in the table below. Data which may be compared are timeliness, range and dominant feature. . Table 1. Comparison of chosen quality management conceptions Conception/Standard Timeliness Range Dominant feature Quality management Used since the 80' XX Used in every Formal and bureaucratic, system ISO 9000 century until today organization. There is no but allowing freedom in geographic, political and the interpretation and cultural boundaries application Standard compliance- Used since the 70' XX Range limited to industry Formal and bureaucratic, requirements of century until today not flexible industry standards TOM Known since the 80' XX Known and introduced to Appeal for common century until today organizations all over the commitment and world improvement Kaizen Known since the 80' XX Used in organizations in Similar to TOM century until today which Japanese culture of work is accepted Six Sigma Known since the 80' XX For now limited, used Based on planning of century, but widely mostly in big venture which goal is to disseminated only from organizations measure the last 10 years effectiveness of activity 154 M. Konieczna cont. table 1 SPC (Statistical Process Control) Beginnings from the 30 XX century (Shewhart), but widely known during 70 and 80 Based on statistical tools and methods Used in organizations with mass production, now a fixed component in automotive industry standards Source: Hamrol, 2007. To achieve the goals and realize the tasks of every organization it is needed to have some funds that enable to form the quality of the products at every stage of the product life cycle. In literature different techniques and methods supporting quality management may be found. They may be divided into: Conceptions and principles of quality management - by using the principles of quality management in practice the organization can strengthen its position on the market, increase the revenue and achieve other benefits. They help in establishing the strategy and goals of the company. The examples can be TQM, Six Sigma or Kaizen. Tools of quality management in quality management the strategic and operational decisions at every stage of production process should be made based on facts. To gain actual data, tools of quality management are essential. They are usually divided into traditional and new tools. The examples are a block diagram, Ishikawa diagram, Pareto diagram, histogram, correlation graphs, control card. Methods of quality management the methods are more complex than tools. Using methods of quality management requires knowledge from statistics, data processing and consequence. In every method the set of tools are used. The examples can be: Quality Function Deployment, value analysis, FMEA, Statistical Process Control (Hamrol, 2017). Although the term of quality is difficult to clearly define and measure, it is essential to take care of it in an organization. The main determinant of quality nowadays is a customer and his needs and expectations which should be met in order to achieve his satisfaction. The companies need to focus on development and improvement of all the processes and in general its functioning. Different types of quality management system may be found in different organizations. It is important to choose the best practice adequate to the branch and activity of the company. . 3. The concept of Six Sigma Six Sigma is an implementation of proven quality in organization. Sigma is a Greek letter used in statistics to measure the variability in the process. The performance of the company is measured by the sigma level in their process. Most of the companies agree on three or four Quality improvement in production enterprise... 155 sigma performance levels as a norm, but it may be seen that in these cases the processes create between 6210 and 66807 defects per million opportunities. In order to meet all the customers' needs and expectations that are still increasing, the Six Sigma program may be introduced and implemented in organization. At the Six Sigma level there are 3.4 defects for million opportunities. Six Sigma is based on reliable and valuable methods that are commonly known. It refuses the whole complexity which characterizes Total Quality Management (TQM). It was counted that there were around 400 different methods and tools connected with TOM which may be overwhelming and difficult to implement and use. Six Sigma based on smaller amount of methods and tools and trains leaders who are known as Master Black Belts and have theoretical and practical knowledge about proven methods (Pyzdek, 2013). Six Sigma may be characterized by six principles: concentration on customer, based on facts, process approach for improvements and management, proactive management, cooperation without boundaries, toleration of defects, but set for perfection (www.projekty.4innovations.pl/2009/08/ charakterystyka-metody-six-sigma). Sigma Performance Scale is presented below in the form of table. It shows the defects per million opportunities, percentage of good products and estimated cost or poor quality according to Sigma level which may occur in organization. . . . . Table 2. Sigma Performance Scale Sigma level Defects for million opportunities (DPMO) 1 sigma 690 000 2 sigma 308 537 (uncompetitive enterprises) 3 sigma 66 807 4 sigma 6210 (average enterprises) 5 sigma 233 6 sigma 3.4 (world's leaders) Source: Watson, 2005. Percentage of good products 31% 69.14% Estimated Cost or Poor Quality (% Revenue) >40% 30-40% 93.32% 99.38% 99.97% 99.99% 20-30% 15-20% 10-15%