Answered step by step

Verified Expert Solution

Question

1 Approved Answer

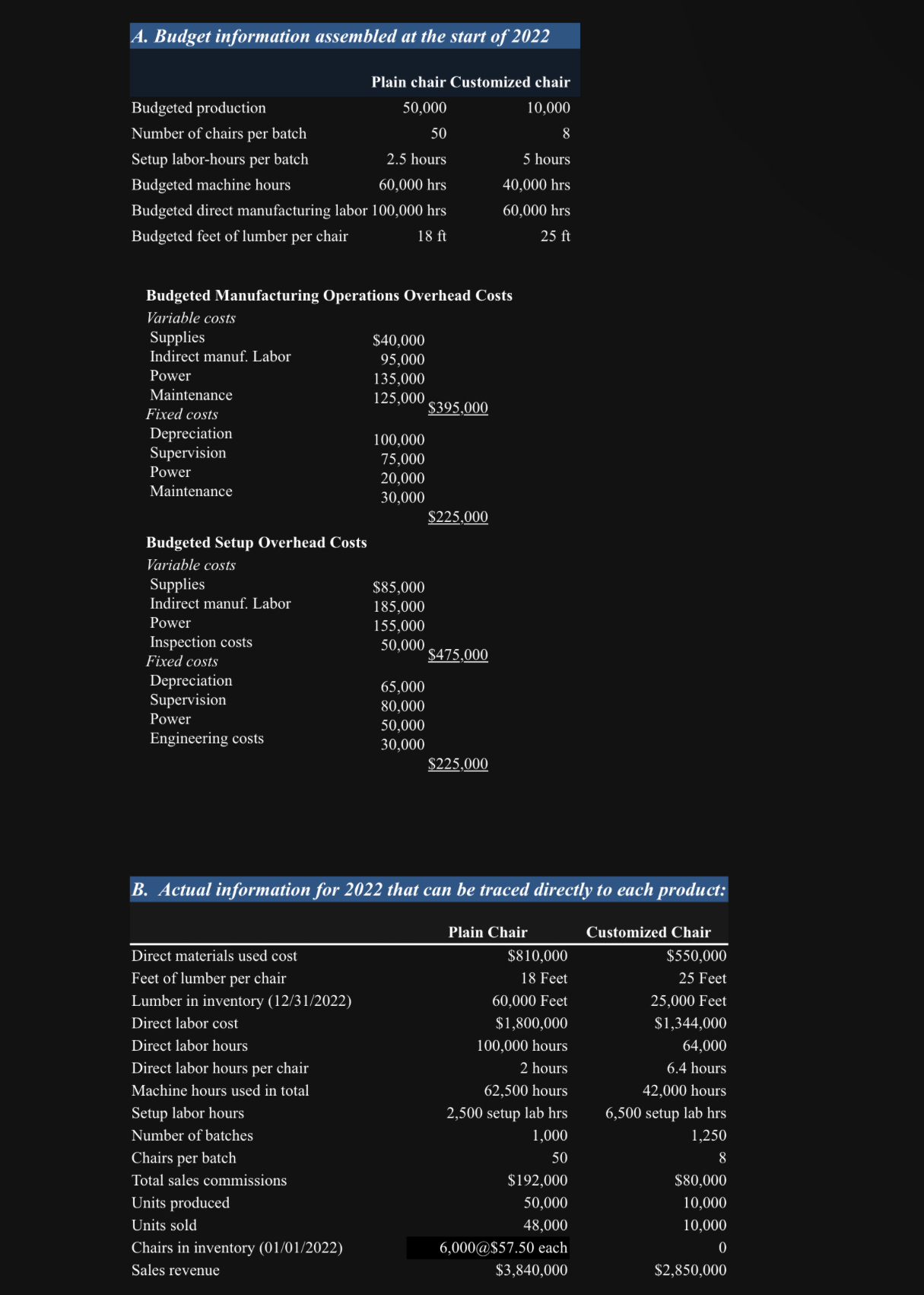

Requirements for Part 2 due Friday, November 1 7 Budgeting, Variance Analysis, and Standard Costing / Variance Analysis. 8 . Compute the sales budget, the

Requirements for Part due Friday, November

Budgeting, Variance Analysis, and Standard CostingVariance Analysis.

Compute the sales budget, the production budget, the direct material usage and purchases budget, the

direct labor budget, the manufacturing overhead budget, the ending inventories budget, the cost of

goods sold budget, the selling and administration budget, the budgeted income statement, and the

cash budget for

Skip to the end of At the end of the following actual quantities and costs were recorded:

A total of plain chairs and customized chairs were produced and sold in at

average selling prices of $ and $ respectively. A total of feet of Poplar wood

was purchased for the plain chairs at a cost of $ A total of feet of Red oak wood

was purchased for the customized chairs at a cost of $ feet of lumber were used

to produce the plain chairs, and feet of lumber were used to create the customized chairs.

direct labor hours were traced to the plain chairs, and direct labor hours were traced

to the customized chairs. A total of $ in wages was paid to the manufacturing workers

traced to plain $ and customized $ workers Actual machine hours were

and for the plain and customized chairs, respectively. Further, for manufacturing operations

overhead actual fixed costs were $ and actual variable costs were $ For machine

setup overhead costs, actual fixed costs were $ and actual variable costs were $

Plain chairs were produced in batches of chairs and used hours per batch. Customized chairs

were produced in batches, on average, of chairs and used hours per batch.

a Calculate the direct material price variance, the direct material efficiency variance, the direct

labor price variance, and the direct labor efficiency variance for each of the product lines

separately. Also, for each overhead activity calculate the FMOH spending and production

volume variances for the Chair division and the VMOH spending and efficiency variances

for the two products.

b Which of the variances that you calculated should you investigate and why? Provide

possible reasons for the variances.Plain chair Customized chair

Budgeted production

Number of chairs per batch

Setup laborhours per batch

Budgeted machine hours

Budgeted direct manufacturing labor

Budgeted feet of lumber per chair

hours

hours

hrs

Budgeted Manufacturing Operations Overhead Costs

Variable costs

Supplies $

Indirect manuf. Labor

Power

Maintenance

Fixed costs $$

Depreciation

Supervision

Power

Maintenance

$

Budgeted Setup Overhead Costs

Variable costs

$

B Actual information for that can be traced directly to each product:

Plain Chair

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started