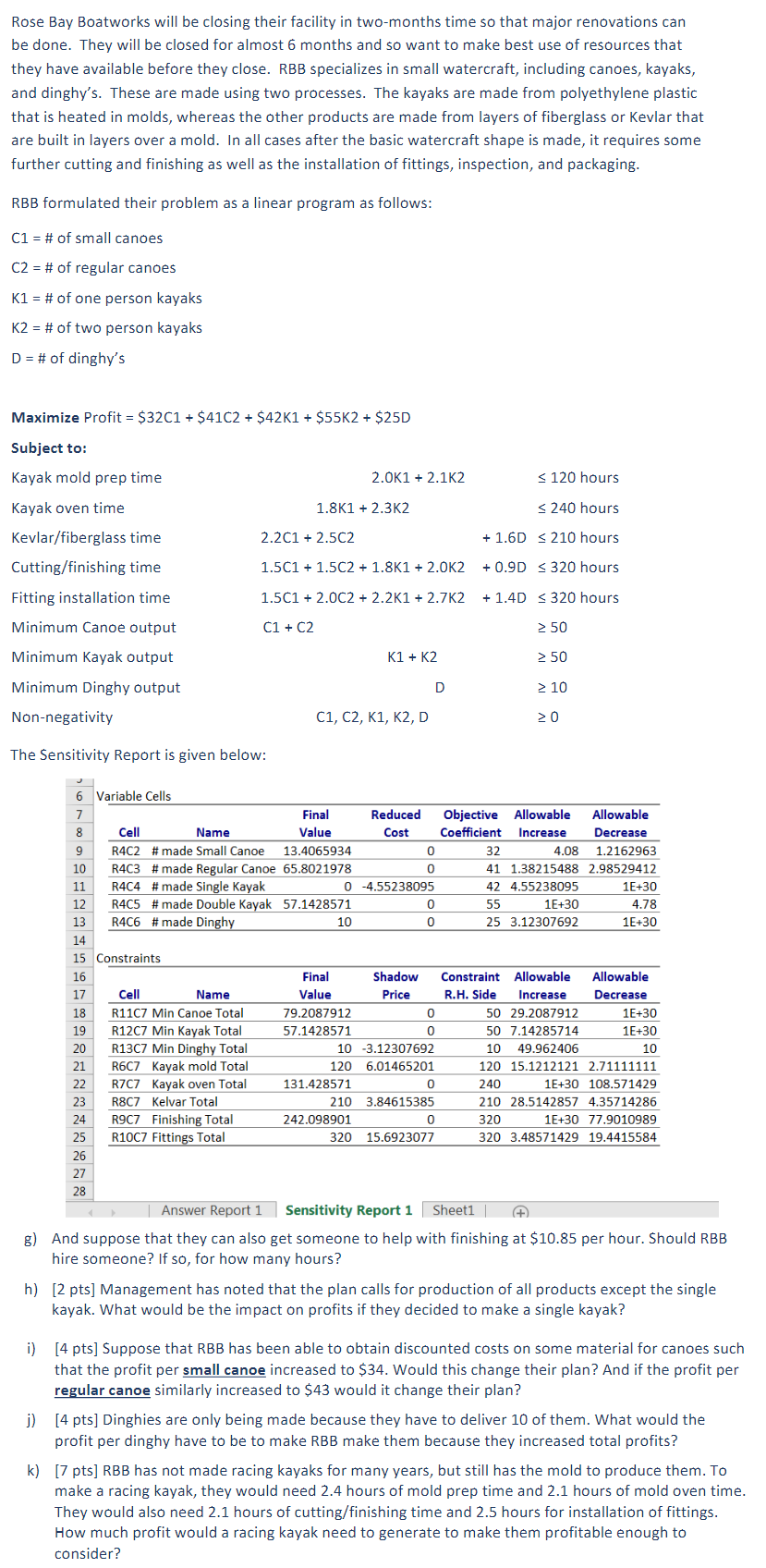

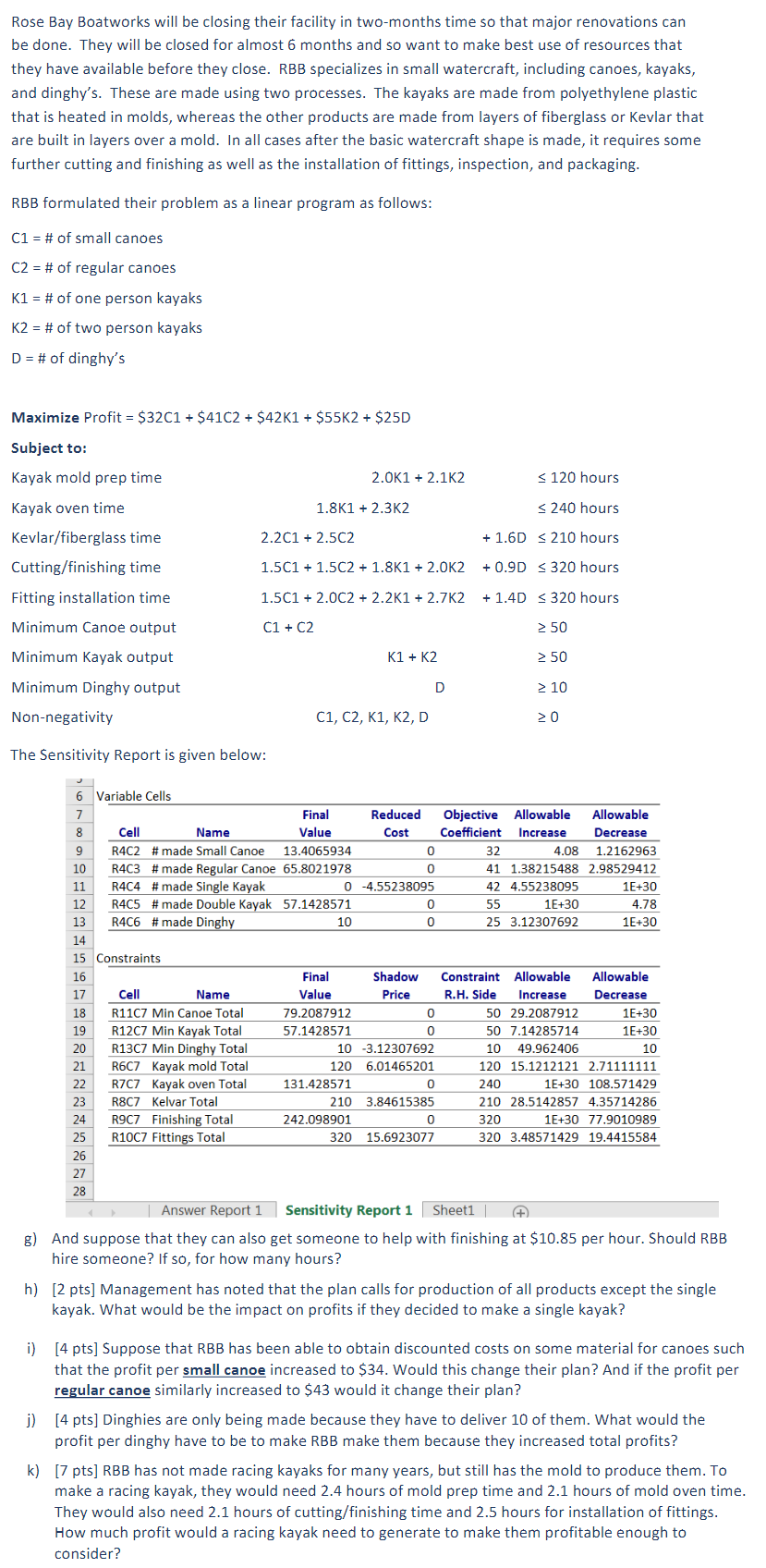

Rose Bay Boatworks will be closing their facility in two-months time so that major renovations can be done. They will be closed for almost 6 months and so want to make best use of resources that they have available before they close. RBB specializes in small watercraft, including canoes, kayaks, and dinghy's. These are made using two processes. The kayaks are made from polyethylene plastic that is heated in molds, whereas the other products are made from layers of fiberglass or Kevlar that are built in layers over a mold. In all cases after the basic watercraft shape is made, it requires some further cutting and finishing as well as the installation of fittings, inspection, and packaging. RBB formulated their problem as a linear program as follows: C1 = # of small canoes C2 = # of regular canoes K1 = # of one person kayaks K2 = # of two person kayaks D = # of dinghy's Maximize Profit = $32C1 + $41C2 + $42K1 + $55K2 + $25D 2.0K1 + 2.1K2 50 Minimum Kayak output K1 + K2 > 50 Minimum Dinghy output D > 10 Non-negativity C1, C2, K1, K2, D 20 The Sensitivity Report is given below: 6 Variable Cells 7 Final Reduced Objective Allowable Allowable 8 Cell Name Value Cost Coefficient Increase Decrease 9 R4C2 #made Small Canoe 13.4065934 0 32 4.08 1.2162963 10 R4C3 #made Regular Canoe 65.8021978 0 41 1.38215488 2.98529412 11 R4C4 #made Single Kayak 0 -4.55238095 42 4.55238095 1E+30 12 R4C5 #made Double Kayak 57.1428571 o 55 1E+30 4.78 13 R4C6 #made Dinghy 10 0 25 3.12307692 1E+30 14 15 Constraints 16 Final Shadow Constraint Allowable Allowable 17 Cell Name Value Price R.H. Side Increase Decrease 18 R1107 Min Canoe Total 79.2087912 0 50 29.2087912 1E+30 19 R12C7 Min Kayak Total 57.1428571 0 50 7.14285714 1E+30 20 R13C7 Min Dinghy Total 10 -3.12307692 10 49.962406 10 21 R6C7 Kayak mold Total 120 6.01465201 120 15.1212121 2.71111111 22 R7C7 Kayak oven Total 131.428571 0 240 1E+30 108.571429 23 R8C7 Kelvar Total 210 3.84615385 210 28.5142857 4.35714286 24 R9C7 Finishing Total 242.098901 0 320 1E+30 77.9010989 25 R10C7 Fittings Total 320 15.6923077 320 3.48571429 19.4415584 26 27 28 Answer Report 1 Sensitivity Report 1 Sheet1 g) And suppose that they can also get someone to help with finishing at $10.85 per hour. Should RBB hire someone? If so, for how many hours? h) [2 pts] Management has noted that the plan calls for production of all products except the single kayak. What would be the impact on profits if they decided to make a single kayak? i) [4 pts] Suppose that RBB has been able to obtain discounted costs on some material for canoes such that the profit per small canoe increased to $34. Would this change their plan? And if the profit per regular canoe similarly increased to $43 would it change their plan? j) [4 pts] Dinghies are only being made because they have to deliver 10 of them. What would the profit per dinghy have to be to make RBB make them because they increased total profits? k) [7 pts] RBB has not made racing kayaks for many years, but still has the mold to produce them. To make a racing kayak, they would need 2.4 hours of mold prep time and 2.1 hours of mold oven time. They would also need 2.1 hours of cutting/finishing time and 2.5 hours for installation of fittings. How much profit would a racing kayak need to generate to make them profitable enough to consider? Rose Bay Boatworks will be closing their facility in two-months time so that major renovations can be done. They will be closed for almost 6 months and so want to make best use of resources that they have available before they close. RBB specializes in small watercraft, including canoes, kayaks, and dinghy's. These are made using two processes. The kayaks are made from polyethylene plastic that is heated in molds, whereas the other products are made from layers of fiberglass or Kevlar that are built in layers over a mold. In all cases after the basic watercraft shape is made, it requires some further cutting and finishing as well as the installation of fittings, inspection, and packaging. RBB formulated their problem as a linear program as follows: C1 = # of small canoes C2 = # of regular canoes K1 = # of one person kayaks K2 = # of two person kayaks D = # of dinghy's Maximize Profit = $32C1 + $41C2 + $42K1 + $55K2 + $25D 2.0K1 + 2.1K2 50 Minimum Kayak output K1 + K2 > 50 Minimum Dinghy output D > 10 Non-negativity C1, C2, K1, K2, D 20 The Sensitivity Report is given below: 6 Variable Cells 7 Final Reduced Objective Allowable Allowable 8 Cell Name Value Cost Coefficient Increase Decrease 9 R4C2 #made Small Canoe 13.4065934 0 32 4.08 1.2162963 10 R4C3 #made Regular Canoe 65.8021978 0 41 1.38215488 2.98529412 11 R4C4 #made Single Kayak 0 -4.55238095 42 4.55238095 1E+30 12 R4C5 #made Double Kayak 57.1428571 o 55 1E+30 4.78 13 R4C6 #made Dinghy 10 0 25 3.12307692 1E+30 14 15 Constraints 16 Final Shadow Constraint Allowable Allowable 17 Cell Name Value Price R.H. Side Increase Decrease 18 R1107 Min Canoe Total 79.2087912 0 50 29.2087912 1E+30 19 R12C7 Min Kayak Total 57.1428571 0 50 7.14285714 1E+30 20 R13C7 Min Dinghy Total 10 -3.12307692 10 49.962406 10 21 R6C7 Kayak mold Total 120 6.01465201 120 15.1212121 2.71111111 22 R7C7 Kayak oven Total 131.428571 0 240 1E+30 108.571429 23 R8C7 Kelvar Total 210 3.84615385 210 28.5142857 4.35714286 24 R9C7 Finishing Total 242.098901 0 320 1E+30 77.9010989 25 R10C7 Fittings Total 320 15.6923077 320 3.48571429 19.4415584 26 27 28 Answer Report 1 Sensitivity Report 1 Sheet1 g) And suppose that they can also get someone to help with finishing at $10.85 per hour. Should RBB hire someone? If so, for how many hours? h) [2 pts] Management has noted that the plan calls for production of all products except the single kayak. What would be the impact on profits if they decided to make a single kayak? i) [4 pts] Suppose that RBB has been able to obtain discounted costs on some material for canoes such that the profit per small canoe increased to $34. Would this change their plan? And if the profit per regular canoe similarly increased to $43 would it change their plan? j) [4 pts] Dinghies are only being made because they have to deliver 10 of them. What would the profit per dinghy have to be to make RBB make them because they increased total profits? k) [7 pts] RBB has not made racing kayaks for many years, but still has the mold to produce them. To make a racing kayak, they would need 2.4 hours of mold prep time and 2.1 hours of mold oven time. They would also need 2.1 hours of cutting/finishing time and 2.5 hours for installation of fittings. How much profit would a racing kayak need to generate to make them profitable enough to consider