Answered step by step

Verified Expert Solution

Question

1 Approved Answer

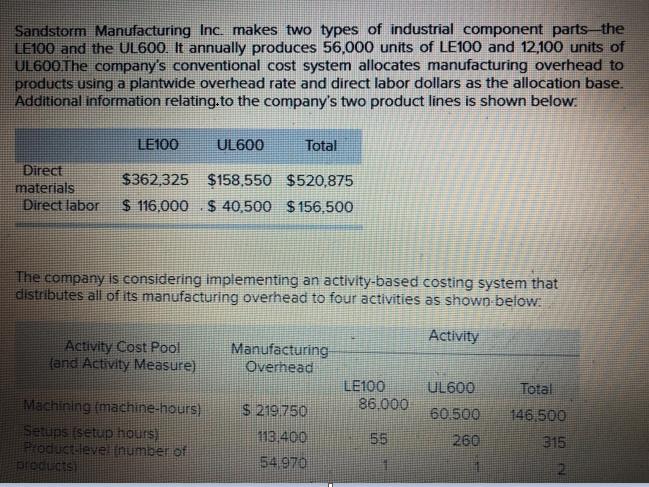

Sandstorm Manufacturing Inc. makes two types of industrial component parts-the LE100 and the UL600. It annually produces 56,000 units of LE100 and 12,100 units

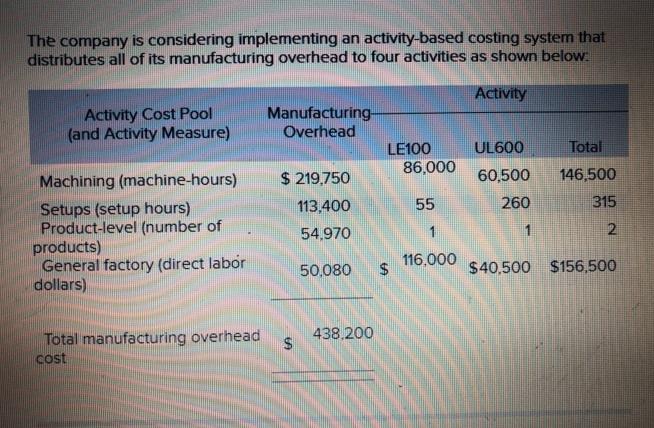

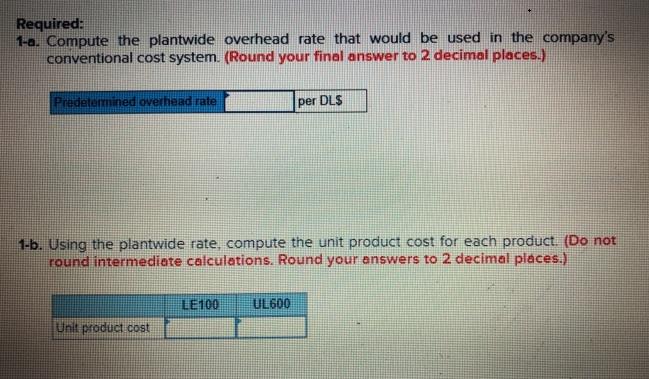

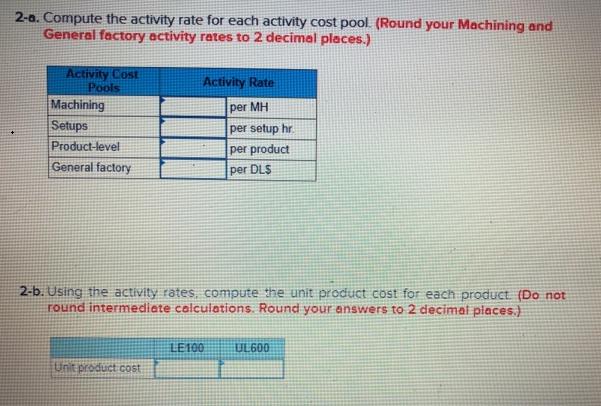

Sandstorm Manufacturing Inc. makes two types of industrial component parts-the LE100 and the UL600. It annually produces 56,000 units of LE100 and 12,100 units of UL600 The company's conventional cost system allocates manufacturing overhead to products using a plantwide overhead rate and direct labor dollars as the allocation base. Additional information relating.to the company's two product lines is shown below: LE100 UL600 Total Direct materials $362,325 $158,550 $520,875 Direct labor $ 116,000 $ 40,500 $156,500 The company is considering implementing an activity-based costing system that distributes all of its manufacturing overhead to four activities as shown below: Activity Activity Cost Pool (and Activity Measure) Manufacturing Overhead LE100 UL600 Total Machining (machine-hours) Setups (setup hours) 86.000 $ 219.750 60.500 146,500 113,400 55 260 315 Product-level (number of products 54.970 2 The company is considering implementing an activity-based costing system that distributes all of its manufacturing overhead to four activities as shown below: Activity Activity Cost Pool Manufacturing- (and Activity Measure) Overhead LE100 UL600 Total 86,000 Machining (machine-hours) $ 219,750 60,500 146,500 Setups (setup hours) 113,400 55 260 315 Product-level (number of 54,970 1 2 products) General factory (direct labor 116,000 50,080 $ $40,500 $156,500 dollars) Total manufacturing overhead cost 5 438.200 Required: 1-a. Compute the plantwide overhead rate that would be used in the company's conventional cost system. (Round your final answer to 2 decimal places.) Predetermined overhead rate per DLS 1-b. Using the plantwide rate, compute the unit product cost for each product. (Do not round intermediate calculations. Round your answers to 2 decimal places.) LE100 UL600 Unit product cost 2-a. Compute the activity rate for each activity cost pool. (Round your Machining and General factory activity rates to 2 decimal places.) Activity Cost Activity Rate Pools Machining Setups per MH per setup hr Product-level General factory per product per DLS 2-b. Using the activity rates, compute the unit product cost for each product. (Do not round intermediate calculations. Round your answers to 2 decimal places.) LE100 UL600 Unit product cost

Step by Step Solution

There are 3 Steps involved in it

Step: 1

The question is incomplete because it does not sp...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started