Answered step by step

Verified Expert Solution

Question

1 Approved Answer

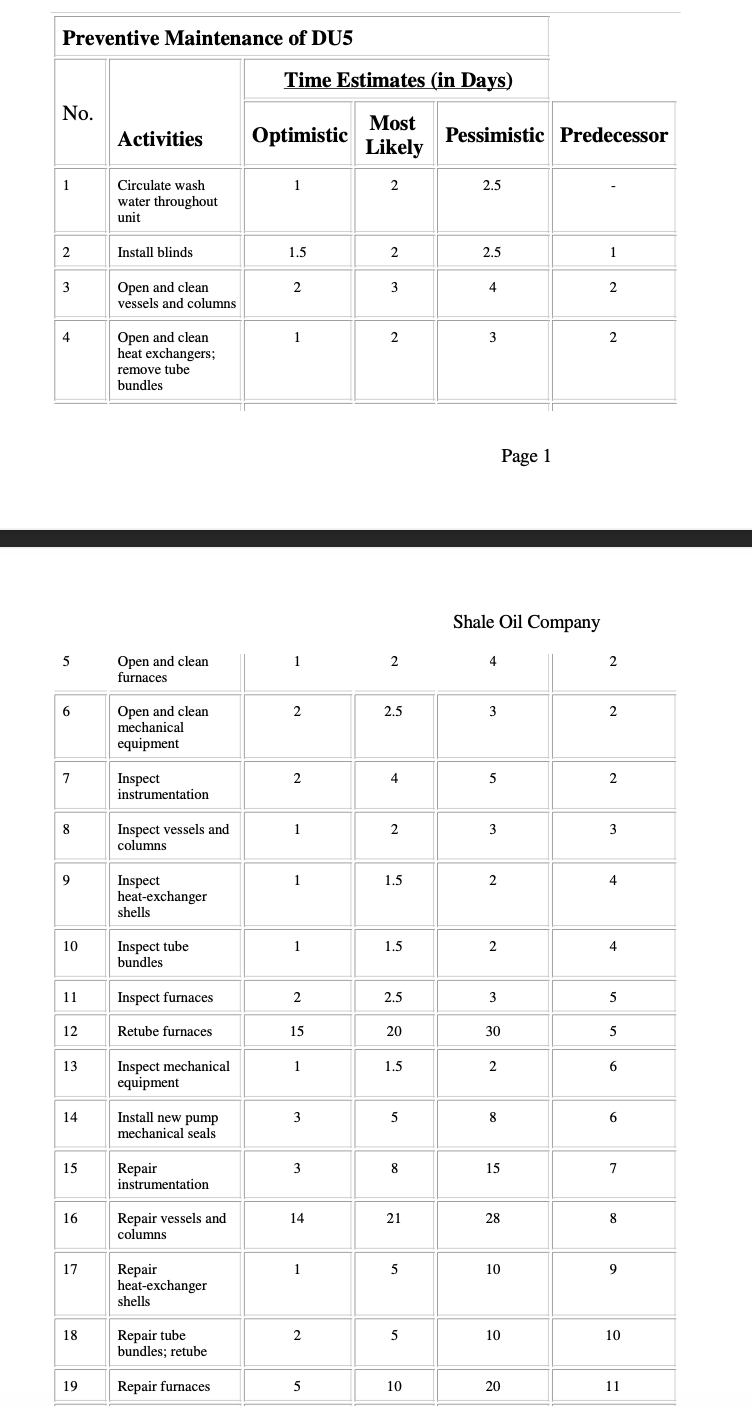

Shale Oil Company s Aston, Ohio, manufacturing complex comprises several operating units. These units process the crude oil that is pumped through and transform it

Shale Oil Companys Aston, Ohio, manufacturing complex comprises several operating units. These units process the crude oil that is pumped through and transform it into a multitude of hydrocarbon products. The units run hours a day, days a week, and must be shut down for maintenance on a predetermined schedule. One such unit is Distillation Unit No or DU Studies have shown that DU can operate only years without major equipment breakdowns, and excessive loss of efficiency. Therefore, DU is shut down every years for cleaning, inspection, and repairs.

DU is the only distillation unit for crude oil in the Aston complex, and its shutdown severely affects all other operating units. Some of the production can be compensated for by Shale refineries in other locations, but the rest must be processed and stored before the shutdown. Without proper planning, a nationwide shortage of Shale gasoline could occur. The time of DUs shutdown is critical, and the length of time the unit is down must be kept to a minimum to limit production loss. Shale uses PERT as a planning and controlling tool to minimize shutdown time.

The first phase of a shutdown is to open and clean the equipment. Inspectors can then enter the unit and examine the damage. Once damages are determined, the needed repairs can be carried out. Repair times can vary considerably, depending on what damage the inspection reveals. Based on previous inspection records, some repair work is known ahead of time. Thorough cleaning of the equipment is also known to improve the units operating efficiency. The table below lists the many maintenance activities and their estimated completion times.

Questions:

Draw the project network using AON method.

Use forward pass to determine ES and EF times.

Use backward pass to determine LS and LF times.

Determine the slack values for each activities and shade the critical path. What is expected project completion time.

List all critical activities. What percent of all activities are critical.

List all noncritical activities.

What is the probability that the shutdown can be completed days earlier than expected project completion time.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started