Answered step by step

Verified Expert Solution

Question

1 Approved Answer

The answers are not 527, 3322, 3801 either. To remain competitive, companies worldwide are increasingly recognizing the need to effectively manage their supply chains. Let

The answers are not 527, 3322, 3801 either.

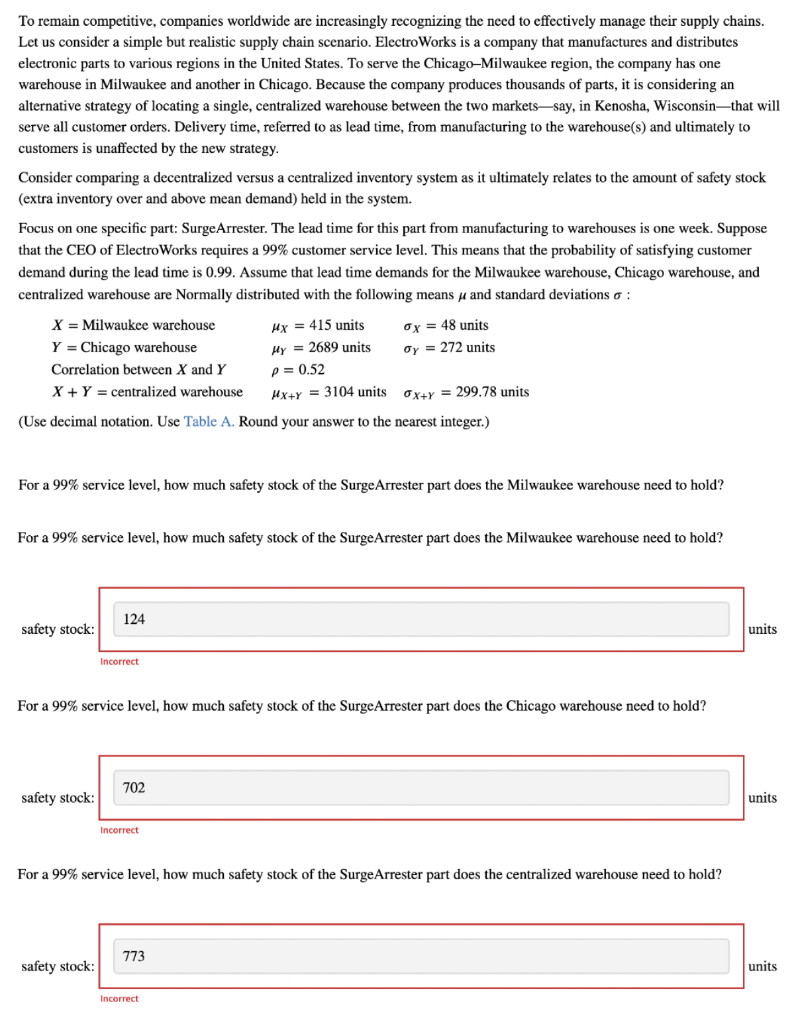

To remain competitive, companies worldwide are increasingly recognizing the need to effectively manage their supply chains. Let us consider a simple but realistic supply chain scenario. ElectroWorks is a company that manufactures and distributes electronic parts to various regions in the United States. To serve the Chicago-Milwaukee region, the company has one warehouse in Milwaukee and another in Chicago. Because the company produces thousands of parts, it is considering an alternative strategy of locating a single, centralized warehouse between the two markets-say, in Kenosha, Wisconsin-that will serve all customer orders. Delivery time, referred to as lead time, from manufacturing to the warehouse(s) and ultimately to customers is unaffected by the new strategy. Consider comparing a decentralized versus a centralized inventory system as it ultimately relates to the amount of safety stock (extra inventory over and above mean demand) held in the system. Focus on one specific part: SurgeArrester. The lead time for this part from manufacturing to warehouses is one week. Suppose that the CEO of ElectroWorks requires a 99% customer service level. This means that the probability of satisfying customer demand during the lead time is 0.99. Assume that lead time demands for the Milwaukee warehouse, Chicago warehouse, and centralized warehouse are Normally distributed with the following means and standard deviations : X=MilwaukeewarehouseY=ChicagowarehouseCorrelationbetweenXandYX+Y=centralizedwarehouseX=415unitsY=2689units=0.52X+Y=3104unitsX=48unitsY=272unitsX+Y=299.78units (Use decimal notation. Use Table A. Round your answer to the nearest integer.) For a 99\% service level, how much safety stock of the SurgeArrester part does the Milwaukee warehouse need to hold? For a 99\% service level, how much safety stock of the SurgeArrester part does the Milwaukee warehouse need to hold? safety stock: units Incorrect For a 99\% service level, how much safety stock of the SurgeArrester part does the Chicago warehouse need to hold? safety stock: Inits Incorrect For a 99\% service level, how much safety stock of the SurgeArrester part does the centralized warehouse need to hold? safety stock: Inits To remain competitive, companies worldwide are increasingly recognizing the need to effectively manage their supply chains. Let us consider a simple but realistic supply chain scenario. ElectroWorks is a company that manufactures and distributes electronic parts to various regions in the United States. To serve the Chicago-Milwaukee region, the company has one warehouse in Milwaukee and another in Chicago. Because the company produces thousands of parts, it is considering an alternative strategy of locating a single, centralized warehouse between the two markets-say, in Kenosha, Wisconsin-that will serve all customer orders. Delivery time, referred to as lead time, from manufacturing to the warehouse(s) and ultimately to customers is unaffected by the new strategy. Consider comparing a decentralized versus a centralized inventory system as it ultimately relates to the amount of safety stock (extra inventory over and above mean demand) held in the system. Focus on one specific part: SurgeArrester. The lead time for this part from manufacturing to warehouses is one week. Suppose that the CEO of ElectroWorks requires a 99% customer service level. This means that the probability of satisfying customer demand during the lead time is 0.99. Assume that lead time demands for the Milwaukee warehouse, Chicago warehouse, and centralized warehouse are Normally distributed with the following means and standard deviations : X=MilwaukeewarehouseY=ChicagowarehouseCorrelationbetweenXandYX+Y=centralizedwarehouseX=415unitsY=2689units=0.52X+Y=3104unitsX=48unitsY=272unitsX+Y=299.78units (Use decimal notation. Use Table A. Round your answer to the nearest integer.) For a 99\% service level, how much safety stock of the SurgeArrester part does the Milwaukee warehouse need to hold? For a 99\% service level, how much safety stock of the SurgeArrester part does the Milwaukee warehouse need to hold? safety stock: units Incorrect For a 99\% service level, how much safety stock of the SurgeArrester part does the Chicago warehouse need to hold? safety stock: Inits Incorrect For a 99\% service level, how much safety stock of the SurgeArrester part does the centralized warehouse need to hold? safety stock: InitsStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started