Answered step by step

Verified Expert Solution

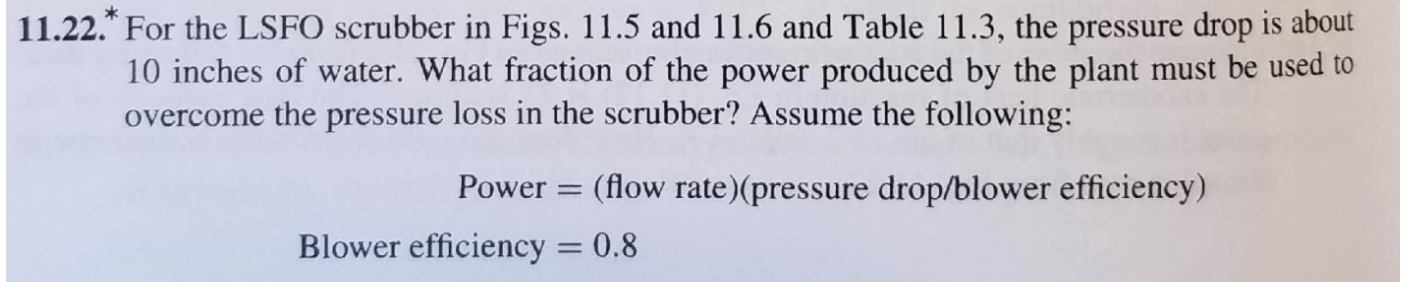

Question

1 Approved Answer

THE CORRECT ANSWER IS: blower uses 0.20% of the plant's total power output to overcome the losses in the scrubber HINT: Look up the actual

THE CORRECT ANSWER IS: blower uses 0.20% of the plant's total power output to overcome the losses in the scrubber

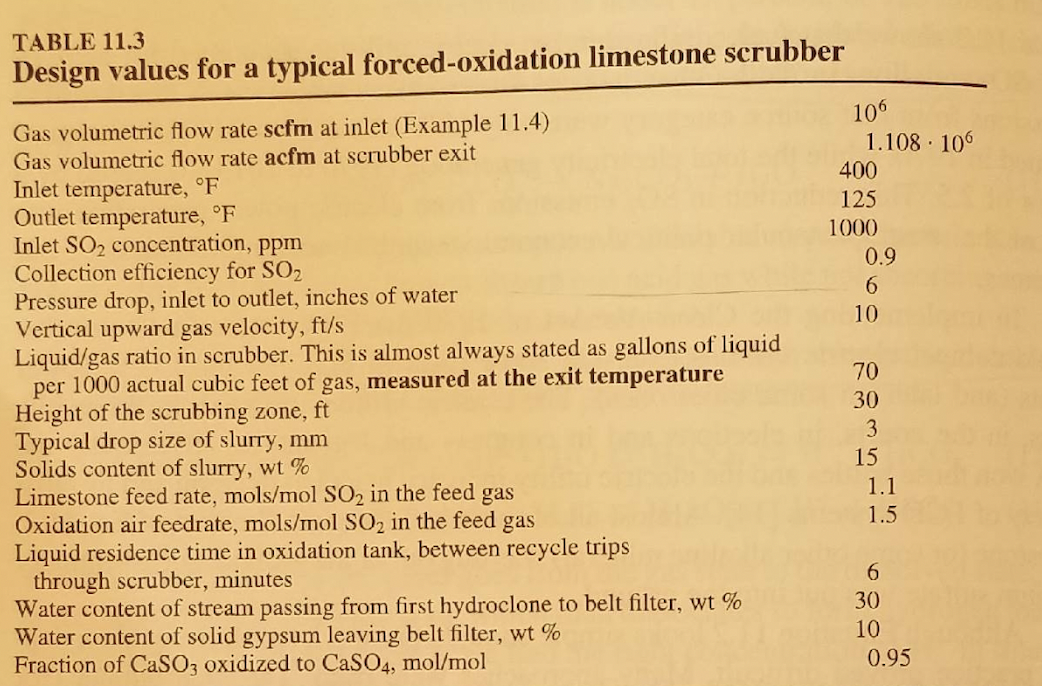

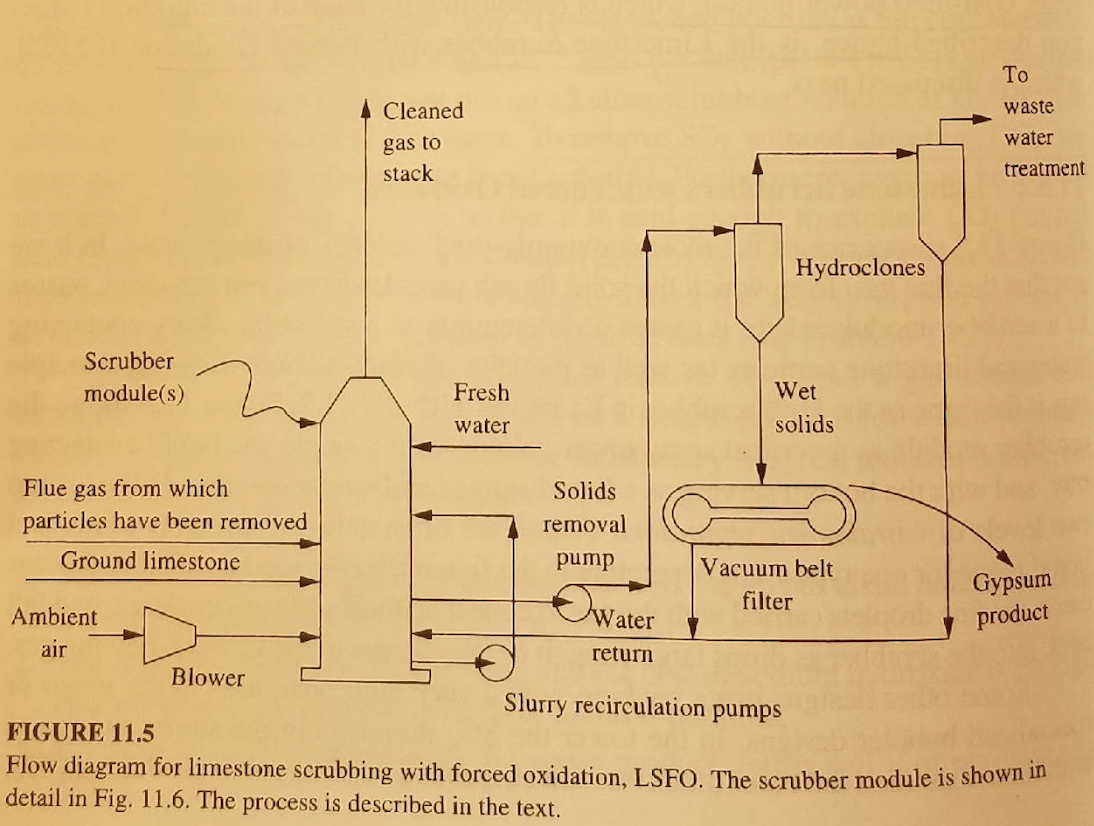

HINT: Look up the actual volumetric flowrate and pressure head drop from Table 11.3 (don't use 10 inches of water). The power plant's total power output is given in example 11.4 (it is 500 MW).

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started