Question

The Goodparts Company produces a component that is subsequently used in the aerospace industry. The component consists of three parts (A, B, and C) that

The Goodparts Company produces a component that is subsequently used in the aerospace industry. The component consists of three parts (A, B, and C) that are purchased from outside and cost 40, 35, and 15 cents per piece, respectively. Parts A and B are assembled first on assembly line 1, which produces 155 components per hour. Part C undergoes a drilling operation before being finally assembled with the output from assembly line 1. There are in total six drilling machines, but at present only three of them are operational. Each drilling machine drills part C at a rate of 50 parts per hour. In the final assembly, the output from assembly line 1 is assembled with the drilled part C. The final assembly line produces at a rate of 175 components per hour. At present, components are produced eight hours a day and five days a week. Management believes that if need arises, it can add a second shift of eight hours for the assembly lines.

The Goodparts Company produces a component that is subsequently used in the aerospace industry. The component consists of three parts (A, B, and C) that are purchased from outside and cost 40, 35, and 15 cents per piece, respectively. Parts A and B are assembled first on assembly line 1, which produces 155 components per hour. Part C undergoes a drilling operation before being finally assembled with the output from assembly line 1. There are in total six drilling machines, but at present only three of them are operational. Each drilling machine drills part C at a rate of 50 parts per hour. In the final assembly, the output from assembly line 1 is assembled with the drilled part C. The final assembly line produces at a rate of 175 components per hour. At present, components are produced eight hours a day and five days a week. Management believes that if need arises, it can add a second shift of eight hours for the assembly lines.

The cost of assembly labor is 25 cents per part for each assembly line; the cost of drilling labor is 10 cents per part. For drilling, the cost of electricity is 2 cent per part. The total overhead cost has been calculated as $1,600 per week. The depreciation cost for equipment has been calculated as $30 per week.

--Determine the cost per unit output for part b. (Round your answer to 2 decimal places.)

cost per unit

--Determine the cost per unit output for part c. (Round your answer to 2 decimal places.)

cost per unit

--

The product is sold at $4 per unit. Assume that the cost of a drilling machine (fixed cost) is $28,000 and the company produces 8,200 units per week. Assume that four drilling machines are used for production. If the company had an option to buy the same part at $3 per unit, what would be the break-even number of units? (In your calculations, use the two-digit cost per unit from page d-1. Round your answer to the nearest whole number.)

-

-

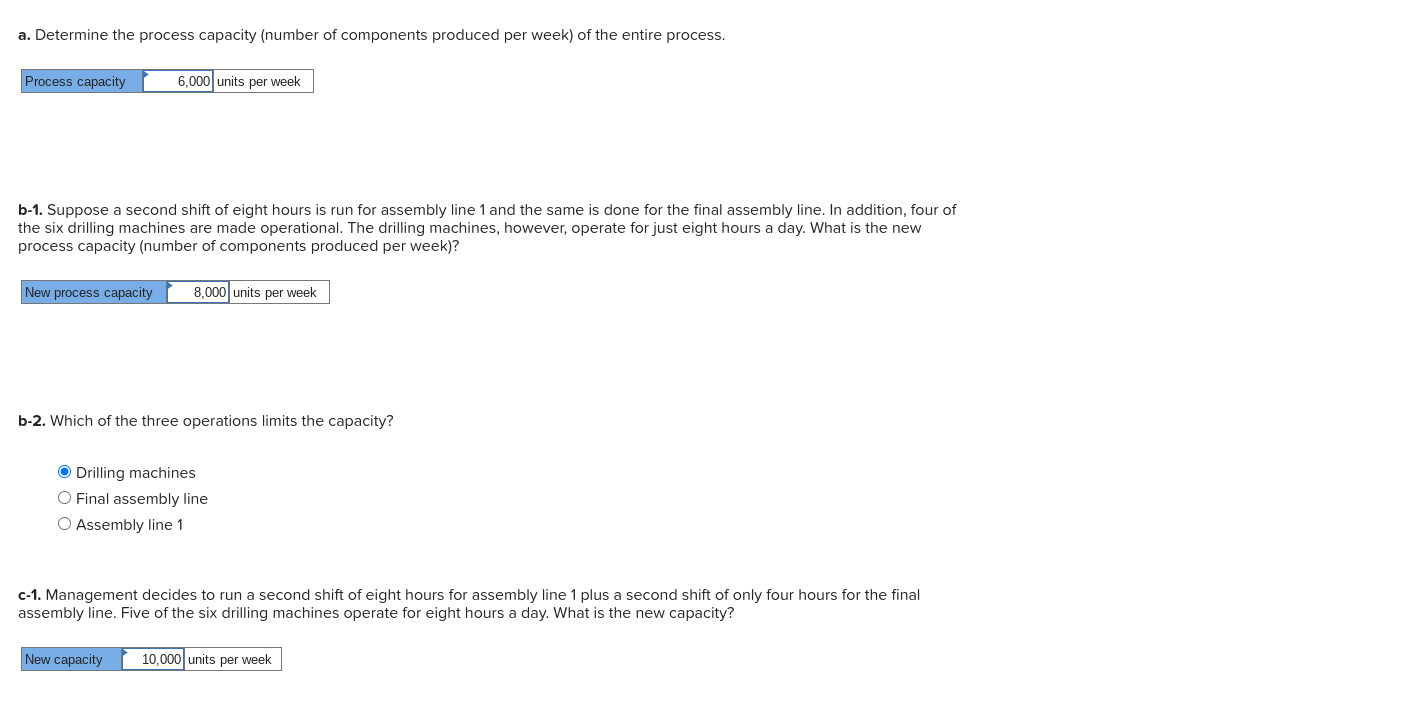

a. Determine the process capacity (number of components produced per week) of the entire process. Process capacity 6,000 units per week b-1. Suppose a second shift of eight hours is run for assembly line 1 and the same is done for the final assembly line. In addition, four of the six drilling machines are made operational. The drilling machines, however, operate for just eight hours a day. What is the new process capacity (number of components produced per week)? New process capacity 8,000 units per week b-2. Which of the three operations limits the capacity? Drilling machines O Final assembly line O Assembly line 1 C-1. Management decides to run a second shift of eight hours for assembly line 1 plus a second shift of only four hours for the final assembly line. Five of the six drilling machines operate for eight hours a day. What is the new capacity? New capacity 10,000 units per weekStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started