Answered step by step

Verified Expert Solution

Question

1 Approved Answer

this is one hole one question Sunset Manufacturers has developed a new style of table that will be made on an assembly line. The schedule

this is one hole one question

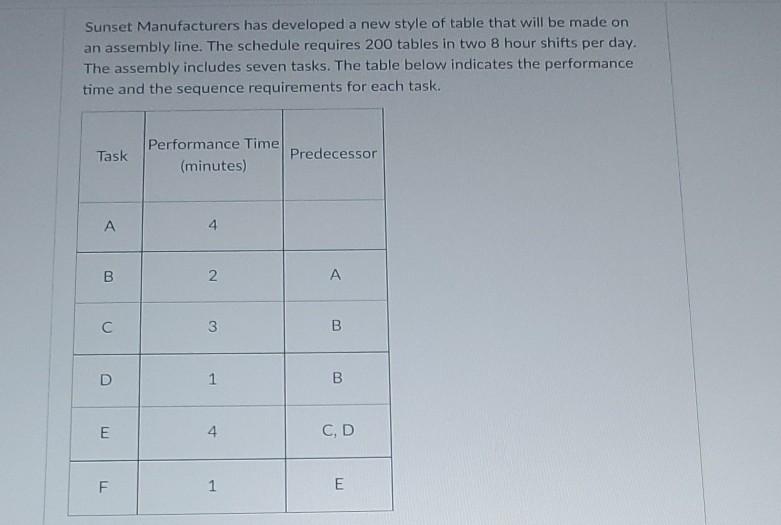

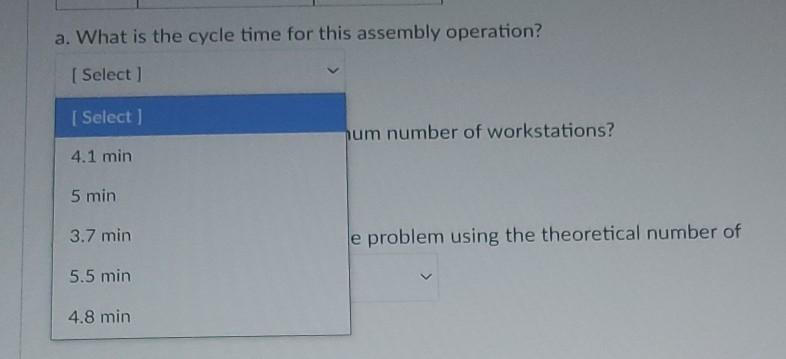

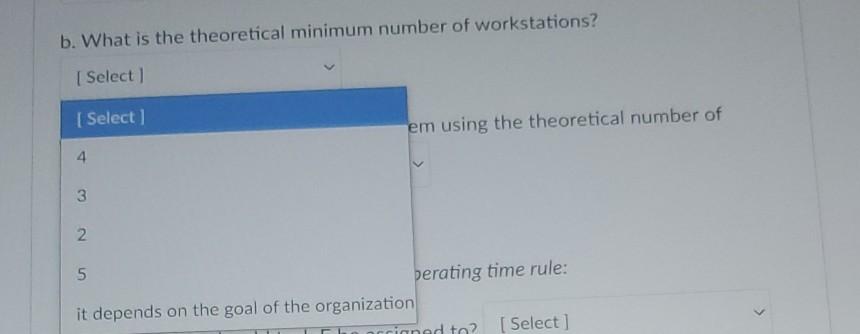

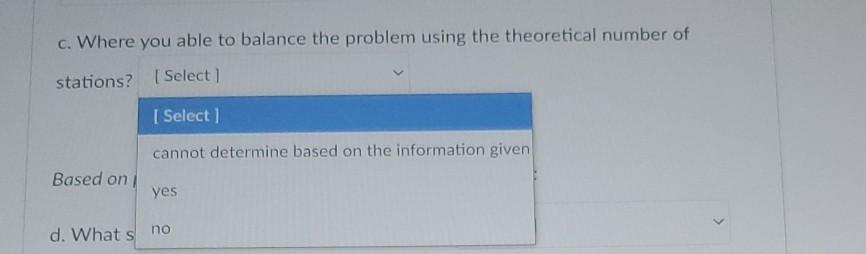

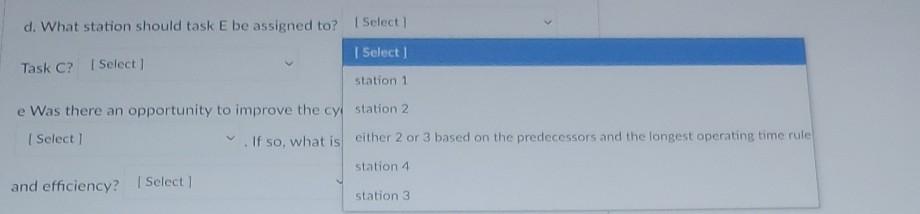

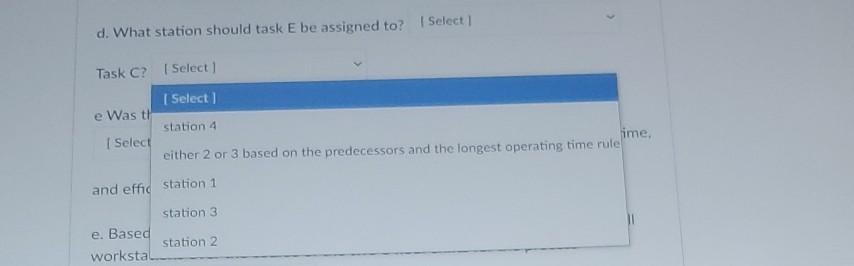

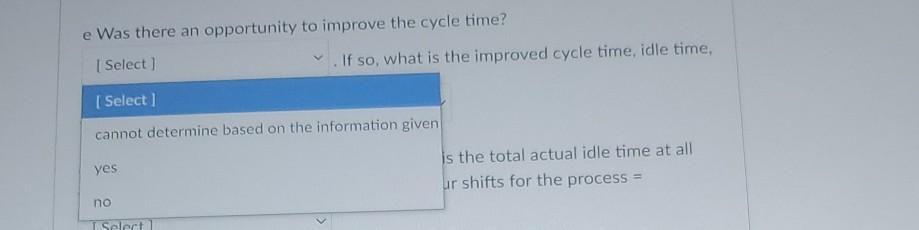

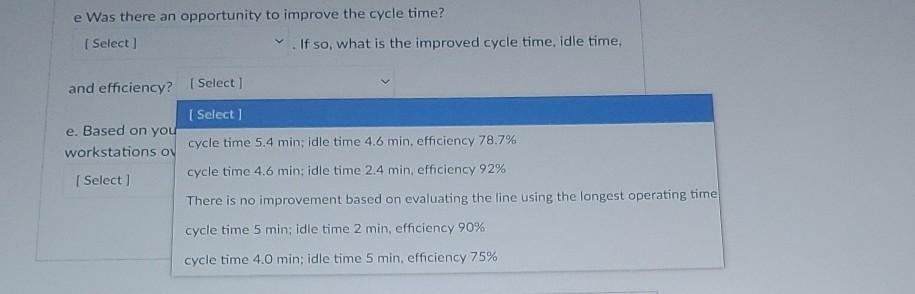

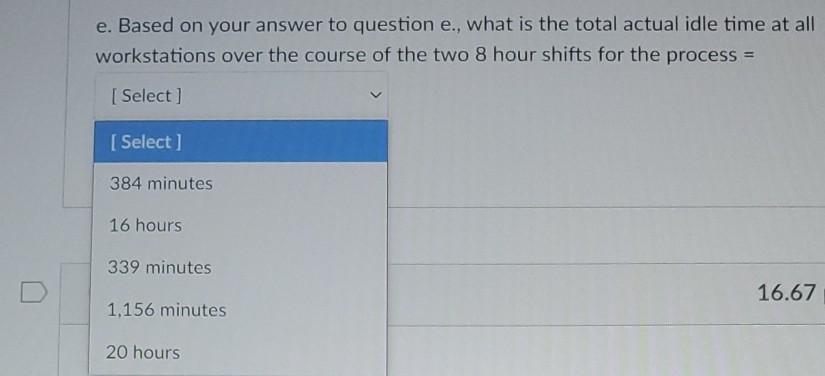

Sunset Manufacturers has developed a new style of table that will be made on an assembly line. The schedule requires 200 tables in two 8 hour shifts per day. The assembly includes seven tasks. The table below indicates the performance time and the sequence requirements for each task. Task Performance Time (minutes) Predecessor A 4 B N 2 A C 3 3 B D 1 B. E 4 CD F 1 E a. What is the cycle time for this assembly operation? [ Select) [ Select) um number of workstations? 4.1 min 5 min 3.7 min e problem using the theoretical number of 5.5 min 4.8 min b. What is the theoretical minimum number of workstations? [ Select) [ Select em using the theoretical number of 4 3 2. 5 perating time rule: it depends on the goal of the organization rigned to? [Select] c. Where you able to balance the problem using the theoretical number of stations? (Select [ Select] cannot determine based on the information given Based on yes d. Whats no d. What station should task E be assigned to? Select | Select Task C? Select station 1 e Was there an opportunity to improve the cystation 2 Select 1 . If so, what is either 2 or 3 based on the predecessors and the longest operating time rule station 4 and efficiency? Select station 3 d. What station should task E be assigned to? Select 1 Task C? Select [ Select) e Was ti station 4 Select either 2 or 3 based on the predecessors and the longest operating time rule ime. and effic station 1 station 3 e. Based workstal station 2 e Was there an opportunity to improve the cycle time? Select) If so, what is the improved cycle time, idle time, [ Select cannot determine based on the information given yes is the total actual idle time at all ur shifts for the process = no I Select e Was there an opportunity to improve the cycle time? Select If so, what is the improved cycle time, idle time, and efficiency? (Select] [ Select] e. Based on you workstations Oy cycle time 5.4 min, idle time 4.6 min. efficiency 78.7% [ Select cycle time 4.6 min: idle time 2.4 min, efficiency 92% There is no improvement based on evaluating the line using the longest operating time cycle time 5 min; idle time 2 min, efficiency 90% cycle time 4.0 min; idle time 5 min, efficiency 75% e. Based on your answer to question e., what is the total actual idle time at all workstations over the course of the two 8 hour shifts for the process = [ Select ] [ Select] 384 minutes 16 hours 339 minutes 16.67 1.156 minutes 20 hours Sunset Manufacturers has developed a new style of table that will be made on an assembly line. The schedule requires 200 tables in two 8 hour shifts per day. The assembly includes seven tasks. The table below indicates the performance time and the sequence requirements for each task. Task Performance Time (minutes) Predecessor A 4 B N 2 A C 3 3 B D 1 B. E 4 CD F 1 E a. What is the cycle time for this assembly operation? [ Select) [ Select) um number of workstations? 4.1 min 5 min 3.7 min e problem using the theoretical number of 5.5 min 4.8 min b. What is the theoretical minimum number of workstations? [ Select) [ Select em using the theoretical number of 4 3 2. 5 perating time rule: it depends on the goal of the organization rigned to? [Select] c. Where you able to balance the problem using the theoretical number of stations? (Select [ Select] cannot determine based on the information given Based on yes d. Whats no d. What station should task E be assigned to? Select | Select Task C? Select station 1 e Was there an opportunity to improve the cystation 2 Select 1 . If so, what is either 2 or 3 based on the predecessors and the longest operating time rule station 4 and efficiency? Select station 3 d. What station should task E be assigned to? Select 1 Task C? Select [ Select) e Was ti station 4 Select either 2 or 3 based on the predecessors and the longest operating time rule ime. and effic station 1 station 3 e. Based workstal station 2 e Was there an opportunity to improve the cycle time? Select) If so, what is the improved cycle time, idle time, [ Select cannot determine based on the information given yes is the total actual idle time at all ur shifts for the process = no I Select e Was there an opportunity to improve the cycle time? Select If so, what is the improved cycle time, idle time, and efficiency? (Select] [ Select] e. Based on you workstations Oy cycle time 5.4 min, idle time 4.6 min. efficiency 78.7% [ Select cycle time 4.6 min: idle time 2.4 min, efficiency 92% There is no improvement based on evaluating the line using the longest operating time cycle time 5 min; idle time 2 min, efficiency 90% cycle time 4.0 min; idle time 5 min, efficiency 75% e. Based on your answer to question e., what is the total actual idle time at all workstations over the course of the two 8 hour shifts for the process = [ Select ] [ Select] 384 minutes 16 hours 339 minutes 16.67 1.156 minutes 20 hoursStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started