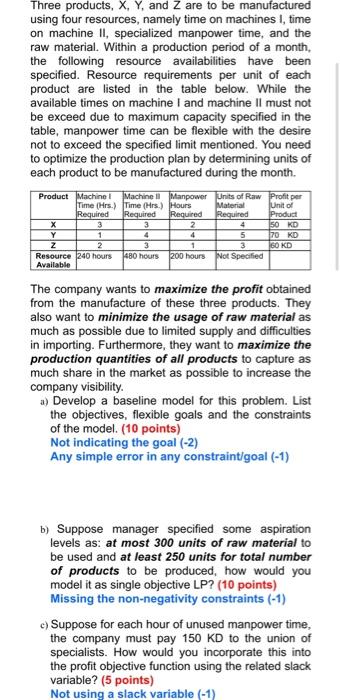

Three products, X,Y, and Z are to be manufactured using four resources, namely time on machines I, time on machine II, specialized manpower time, and the raw material. Within a production period of a month, the following resource availabilities have been specified. Resource requirements per unit of each product are listed in the table below. While the available times on machine I and machine II must not be exceed due to maximum capacity specified in the table, manpower time can be flexible with the desire not to exceed the specified limit mentioned. You need to optimize the production plan by determining units of each product to be manufactured during the month. The company wants to maximize the profit obtained from the manufacture of these three products. They also want to minimize the usage of raw material as much as possible due to limited supply and difficulties in importing. Furthermore, they want to maximize the production quantities of all products to capture as much share in the market as possible to increase the company visibility. a) Develop a baseline model for this problem. List the objectives, flexible goals and the constraints of the model. (10 points) Not indicating the goal (2) Any simple error in any constraint/goal (-1) b) Suppose manager specified some aspiration levels as: at most 300 units of raw material to be used and at least 250 units for total number of products to be produced, how would you model it as single objective LP? (10 points) Missing the non-negativity constraints (1) c) Suppose for each hour of unused manpower time, the company must pay 150KD to the union of specialists. How would you incorporate this into the profit objective function using the related slack variable? (5 points) Not using a slack variable (1) Three products, X,Y, and Z are to be manufactured using four resources, namely time on machines I, time on machine II, specialized manpower time, and the raw material. Within a production period of a month, the following resource availabilities have been specified. Resource requirements per unit of each product are listed in the table below. While the available times on machine I and machine II must not be exceed due to maximum capacity specified in the table, manpower time can be flexible with the desire not to exceed the specified limit mentioned. You need to optimize the production plan by determining units of each product to be manufactured during the month. The company wants to maximize the profit obtained from the manufacture of these three products. They also want to minimize the usage of raw material as much as possible due to limited supply and difficulties in importing. Furthermore, they want to maximize the production quantities of all products to capture as much share in the market as possible to increase the company visibility. a) Develop a baseline model for this problem. List the objectives, flexible goals and the constraints of the model. (10 points) Not indicating the goal (2) Any simple error in any constraint/goal (-1) b) Suppose manager specified some aspiration levels as: at most 300 units of raw material to be used and at least 250 units for total number of products to be produced, how would you model it as single objective LP? (10 points) Missing the non-negativity constraints (1) c) Suppose for each hour of unused manpower time, the company must pay 150KD to the union of specialists. How would you incorporate this into the profit objective function using the related slack variable? (5 points) Not using a slack variable (1)