Question

Toyota Quality Management Toyota is among the few manufactures in the completely automobile industry that consistently profited during the oil crisis in 1974. The discovery

Toyota Quality Management

Toyota is among the few manufactures in the completely automobile industry that consistently profited during the oil crisis in 1974. The discovery was the unique team working of the Japanese that utilizes the scientific management rules (Huczynski & Buchanan, 2007).

The joint effort in Japan, usually dubbed as Toyotaism, is a kind of job association emphasizing on lean-assembly. The technique merges just-in-time production, dilemma answering groups, job equivalence, authoritative foremost-streak administration, and continued procedure perfection.

Just-in-time (JIT) assembly scheme attempts to accomplish all clients needs instantly devoid of misuse but with ideal excellence. JIT appears to be dissimilar from the conventional functional performances in that it emphasizes on speedy production and ravage purging that adds to stumpy supply.

Control and planning of many JIT approaches are concerned directly with pull scheduling, leveled scheduling, kanban control, synchronization of flow, and mixed-model scheduling (Slack et al., 2009).

Toyota appears to be amongst the principal participants in changing Japan to a kingpin in car production. Companies, which have adopted the companys production system, have increased efficiency and productivity. The 2009 industrial survey of manufacturers indicates that many world-class firms have adopted continuous-flow or just-in-time production and many techniques Toyota has been developing many years ago.

In addition, the manufacturing examination of top plant victors illustrates that the mainstream of them utilize lean production techniques widely. Thus, team-working TPS assists Toyota Corporation in the implementation of TQM.

Toyota TQM Implementation Challenges

The Executives and Quality Managers face some challenges while implementing Quality Management Systems in organizations. In fact, with lack of the implementation resources such as monetary and human resources in any organization, the implementation of TQM cannot be successful. Towards the implementation of programs and projects in organizations, the financial and human resources have become the pillar stones.

The approach of TQM impels the marketplace competence from all kinds organizational proceeds to ensure profitability and productivity. To meet the desired results in TQM implementation, an organization ought to consider the availability of human and financial resources that are very important for the provision of appropriate milieu for accomplishing organizational objectives.

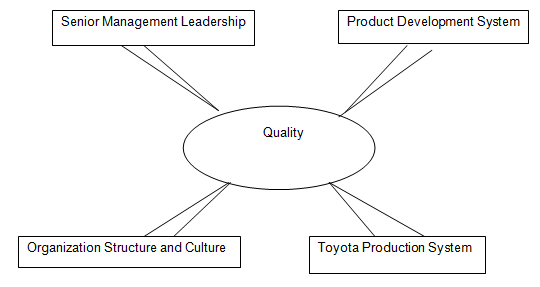

In the case of Toyota that originated and perfected the philosophy of TQM, the Executives and Quality Managers meet some intertwined problems during TQM implementation. The flaw in the new product development is increasingly becoming complicated for the managers to break and accelerate, thus reliability problem. Besides, secretive culture and dysfunctional organizational structure cause barrier in communication between the top management thus, in turn, augmenting public outrage.

The top executives may fail to provide and scale-up adequate training to the suppliers and new workforces. As a result, cracks are created in the rigorous TPS system. In addition, lack of leadership at the top management might cause challenges in the implementation of TQM. Therefore, in designing the organizational structures and systems that impact quality, the senior executives and managers must be responsible as elaborated in the figure2 below.

Conclusion

Total Quality Management is a concept applied in automobile industry, including the Toyota Corporation. It focuses on continuous improvement across all branches and levels of an organization. Being part of Toyota, the concept defines the way in which the organization can create value for its customers and other stakeholders. Through TQM, Toyota Corporation has been able to create value, which eventually leads to operation efficiencies.

These efficiencies have particularly been achieved by continuous correction of deficiencies identified in the process. A particular interest is the central role that information flow and management have played in enabling TQM initiatives to be implemented, especially through continuous learning and team working culture.

The Toyota way (kaizen), which aims at integrating the workforce suggestions while eliminating overproduction and manufacturing wastes helps the company to respect all the stakeholders and give clients first priority. The objectives are realized through TPS.

Read the above article and answer the following questions:

- Define (Kaizen) way?

- Elaborate on the JIT scheme that was adopted by TOYOTA company.

- What are the challenges TOYOTA had faced in implementing TQM.

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started