Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Two groups of indirect labour, general factory labour and tailors, build the recliners. General factory labour does all the manufacturing work except the final

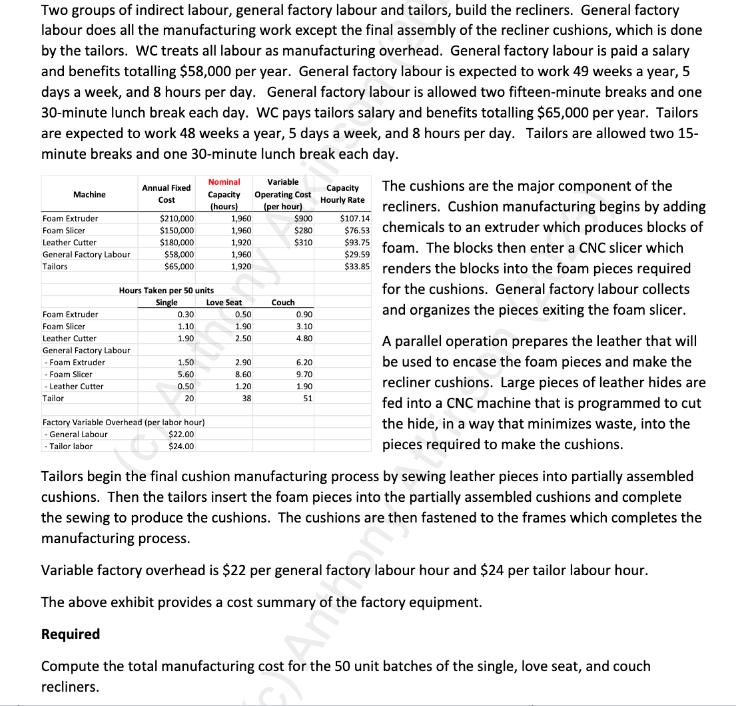

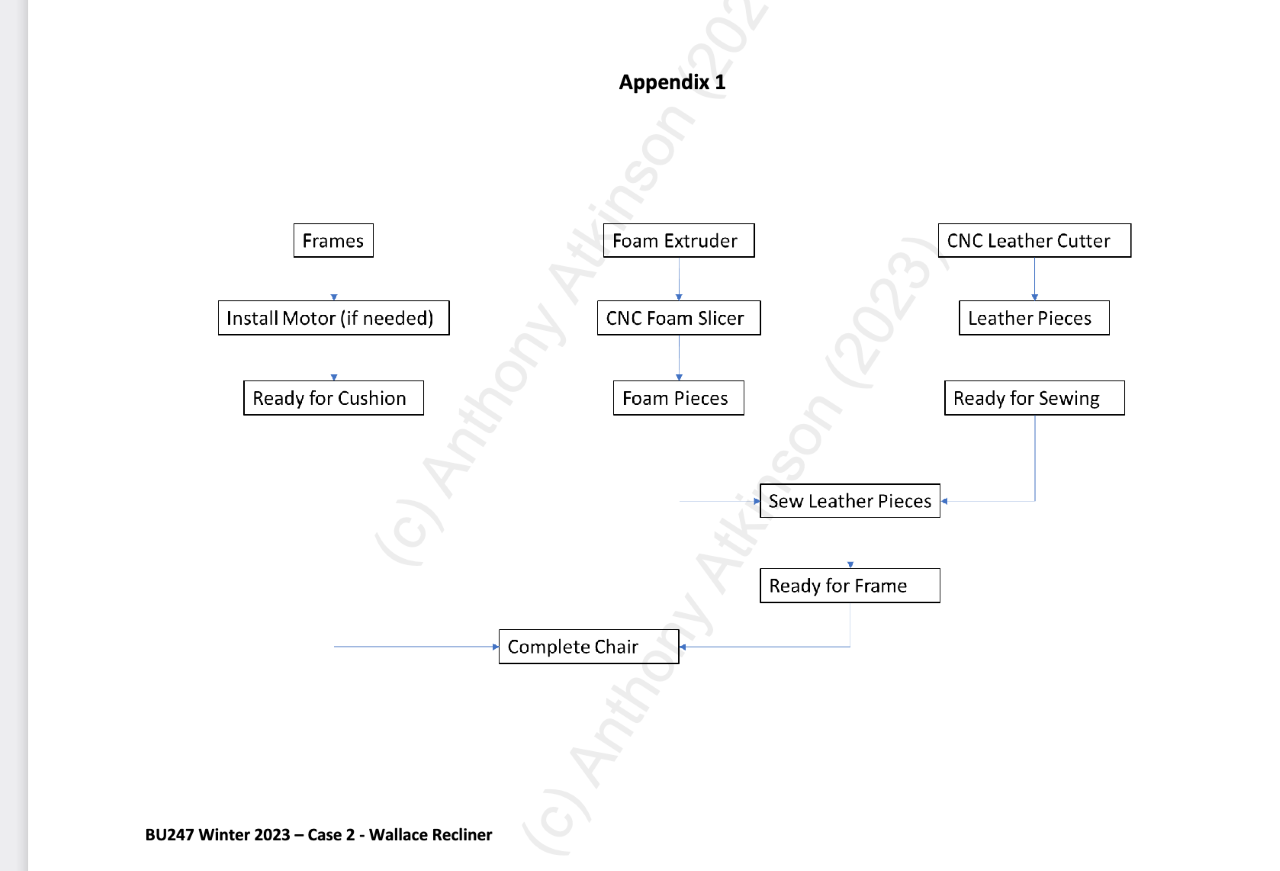

Two groups of indirect labour, general factory labour and tailors, build the recliners. General factory labour does all the manufacturing work except the final assembly of the recliner cushions, which is done by the tailors. WC treats all labour as manufacturing overhead. General factory labour is paid a salary and benefits totalling $58,000 per year. General factory labour is expected to work 49 weeks a year, 5 days a week, and 8 hours per day. General factory labour is allowed two fifteen-minute breaks and one 30-minute lunch break each day. WC pays tailors salary and benefits totalling $65,000 per year. Tailors are expected to work 48 weeks a year, 5 days a week, and 8 hours per day. Tailors are allowed two 15- minute breaks and one 30-minute lunch break each day. Machine Annual Fixed Cost Nominal Capacity Variable Operating Cost (hours) (per hour) Foam Extruder $210,000 1,960 $900 Foam Slicer $150,000 1,960 $280 Leather Cutter $180,000 1,920 $310 General Factory Labour $58,000 1,960 Tailors $65,000 1,9201 Hours Taken per 50 units Single Love Seat Couch Foam Extruder 0.50 0.90 Foam Slicer 1.90 3.10 Leather Cutter 2.50 General Factory Labour -Foam Extruder -Foam Slicer - Leather Cutter Tailor Factory Variable Overhead (per labor hour) -General Labour $22.00 -Tailor labor $24.00 989 4.80 6.20 2.90 8.60 9.70 1.20 38 1.90 51 Capacity Hourly Rate $107.14 The cushions are the major component of the recliners. Cushion manufacturing begins by adding $76.53 chemicals to an extruder which produces blocks of foam. The blocks then enter a CNC slicer which $33.85 renders the blocks into the foam pieces required for the cushions. General factory labour collects and organizes the pieces exiting the foam slicer. $93.75 $29.59 A parallel operation prepares the leather that will be used to encase the foam pieces and make the recliner cushions. Large pieces of leather hides are fed into a CNC machine that is programmed to cut the hide, in a way that minimizes waste, into the pieces required to make the cushions. Tailors begin the final cushion manufacturing process by sewing leather pieces into partially assembled cushions. Then the tailors insert the foam pieces into the partially assembled cushions and complete the sewing to produce the cushions. The cushions are then fastened to the frames which completes the manufacturing process. Variable factory overhead is $22 per general labour hour and $24 per tailor labour hour. The above exhibit provides a cost summary of the factory equipment. Required Compute the total manufacturing cost for the 50 unit batches of the single, love seat, and couch recliners. Frames Foam Extruder (c) Anthony Atranson 202 Install Motor (if needed) Ready for Cushion BU247 Winter 2023 - Case 2 - Wallace Recliner CNC Foam Slicer Foam Pieces Sew Leather Pieces CNC Leather Cutter Leather Pieces Ready for Sewing (c) Anthy Atkson (2023) Complete Chair Ready for Frame

Step by Step Solution

There are 3 Steps involved in it

Step: 1

To compute the total manufacturing cost for the 50 unit batches of the single love seat and couch recliners we need to calculate the following 1 Direc...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started