Question

Using the information below, please prepare. - MOH Budget including cash disbursements for overhead, S&A budget including cash disbursements for S&A, Budgeted Income Statement, Cash

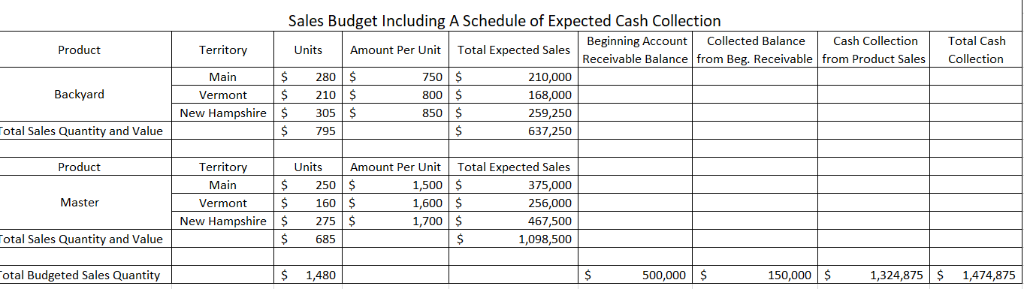

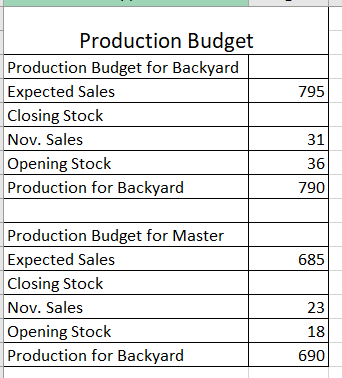

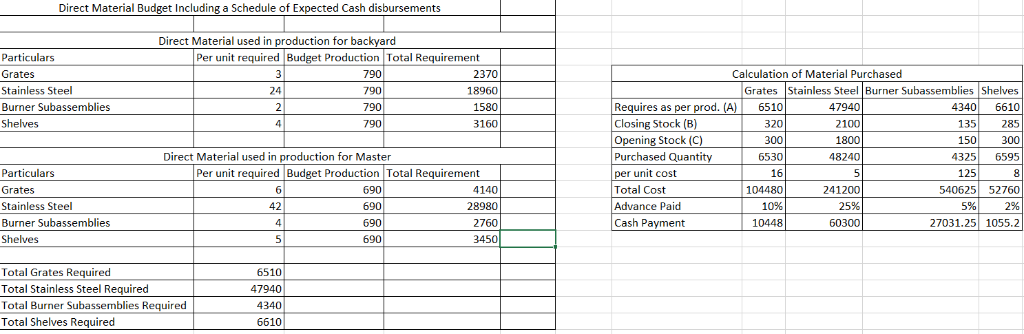

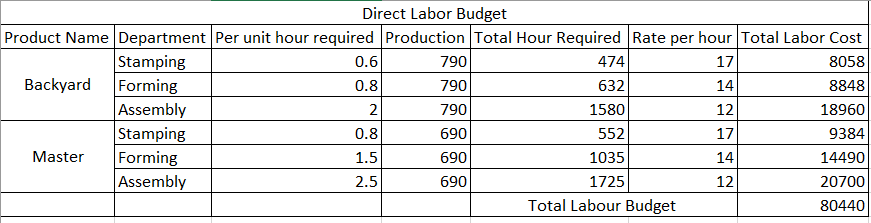

Using the information below, please prepare. - MOH Budget including cash disbursements for overhead, S&A budget including cash disbursements for S&A, Budgeted Income Statement, Cash Budget Selected information concerning sales and production for October 2019 is summarized as follows: a. The sales budget must be divided up by product (Backyard and Master). Estimated sales for October by sales territory: Maine: Vermont: New Hampshire: Backyard 280 units at $750 per unit Backyard 210 units at $800 per unit Backyard 305 units at $850 per unit Master 250 units at $1,500 per unit Master 160 units at $1,600 per unit Master 275 units at $1,700 per unit Estimated sales for November for all territories: Backyard Grills 620 grills Master Grills 1,150 grills Outdoor Chef Grill has a beginning accounts receivable balance of $550,000 in the month of October and expects to collect 30% of that balance. In addition, their accounting department has estimated that 80% of sales for the Master Grill will be paid in cash and 70% of the Backyard grill will be paid in cash. b. Inventory of Grills Beginning Inventory of Grills: Backyard 36 units Master 18 units Outdoor Chef Grill has established a new ending inventory policy to take effect the month of October. From October and going forward, the ending inventory should be: Ending Inventory: Backyard 5% of Novembers sales Master 2% of Novembers sales. c. Estimated direct material inventories at October 1: Direct materials (available for the Master and Backyard Grill): Grates 300 units, Stainless steel 1,800 lbs., Burner subassemblies 150 units, Shelves 300 units Desired inventories at October 31: Direct materials (available for the Master and Backyard Grill): Grates 320 units, Stainless steel 2,100 lbs.,Burner subassemblies 135 units, Shelves 285 units d. Direct materials used in production: Direct Materials required to produce one Backyard Chef Grill: Grates 3 units per unit of product, Stainless steel 24 lbs. per unit of product, Burner subassemblies 2 units per unit of product Shelves 4 units per unit of product Direct Materials required to produce one Master Chef grill: Grates 6 units per unit of product, Stainless steel 42 lbs. per unit of product, Burner subassemblies 4 units per unit of product, Shelves 5 units per unit of product Anticipated purchase price for direct materials: Grates $16 per unit, Stainless steel $5 per lb., Burner subassemblies $125 per unit, Shelves $8 per unit Because of their excellent relationships with the vendors, they pay the following percentages when placing their order: Grates: 10%, Stainless Steel: 25%, Burner subassemblies 5%, Shelves 2%, if pay the entire balance within 35 days. e. Direct labor requirements for one grill: Backyard Chef: Stamping Department 0.60 hr. at $17 per hr., Forming Department 0.80 hr. at $14 per hr., Assembly Department 2.0 hrs. at $12 per hr. Master Chef: Stamping Department .80 hr. at $17 per hr., Forming Department 1.50 hrs. at $14 per hr., Assembly Department 2.50 hrs. at $12 per hr. f. Outdoor Chef Grill Company budgeted the following costs for anticipated production in October. The list below includes fixed MOH expenses and Fixed S&A expenses, Advertising Expenses $24,000, Sales monthly salary (not commission) $7,500, Factory Insurance $5,000, Production Supervisor Salary $4,900, Executive officer salaries $25,000, Indirect Labor Salaries for Quality Control $2,800, Factory Depreciation $4,000, Corporate Office Building Depreciation, $3,000 Total estimated VMOH expenses are $41,000 for the month of October. VMOH expenses are allocated to the products based on a single PDOR rate using the allocation base, Direct Material Cost. FMOH is assigned to the products based on DL hours. Note: You will have two PDORs for this assignment. Variable S&A expenses are allocated at rate of $3 per grill. g. Other Information: a. Income Tax Rate is 35%, b. Minimum Cash Balance $500,000, Beginning Cash Balance $750,000

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started