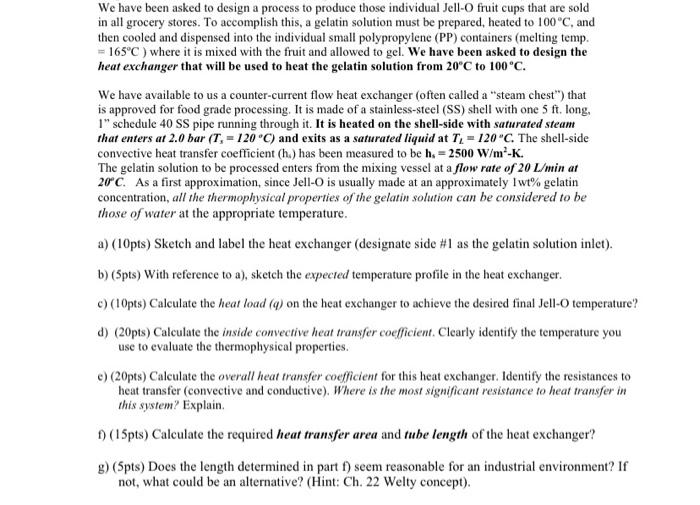

We have been asked to design a process to produce those individual Jell-O fruit cups that are sold in all grocery stores. To accomplish this, a gelatin solution must be prepared, heated to 100C, and then cooled and dispensed into the individual small polypropylene (PP) containers (melting temp. =165C ) where it is mixed with the fruit and allowed to gel. We have been asked to design the heat exchanger that will be used to heat the gelatin solution from 20C to 100C. We have available to us a counter-current flow heat exchanger (often called a "steam chest") that is approved for food grade processing. It is made of a stainless-steel (SS) shell with one 5ft. long. that enters at 2.0 bar (Ts=120C) and exits as a saturated liquid at TL=120C. The shell-side convective heat transfer coefficient (hs) has been measured to be hs=2500W/m2K. The gelatin solution to be processed enters from the mixing vessel at a flow rate of 20L/min at 20C. As a first approximation, since Jell-O is usually made at an approximately 1wt% gelatin concentration, all the thermophysical properties of the gelatin solution can be considered to be those of water at the appropriate temperature. a) (10pts) Sketch and label the heat exchanger (designate side #1 as the gelatin solution inlet). b) (5pts) With reference to a), sketch the expected temperature profile in the heat exchanger. c) (10pts) Calculate the heat load ( q ) on the heat exchanger to achieve the desired final Jell-O temperature? d) (20pts) Calculate the inside convective heat transfer coefficient. Clearly identify the temperature you use to evaluate the thermophysical properties. e) (20pts) Calculate the overall heat transfer coefficient for this heat exchanger. Identify the resistances to heat transfer (convective and conductive). Where is the most significant resistance to heat transfer in this system? Explain. f) ( 15pts) Calculate the required heat transfer area and tube length of the heat exchanger? g) (5pts) Does the length determined in part f ) seem reasonable for an industrial environment? If not, what could be an alternative? (Hint: Ch. 22 Welty concept)