Answered step by step

Verified Expert Solution

Question

1 Approved Answer

What are misconceptions about supply chain agility and how can they be overcome? What is supply chain agility? Responding autonomously means responding to In essence,

What are misconceptions about supply chain agility and how can they be overcome?

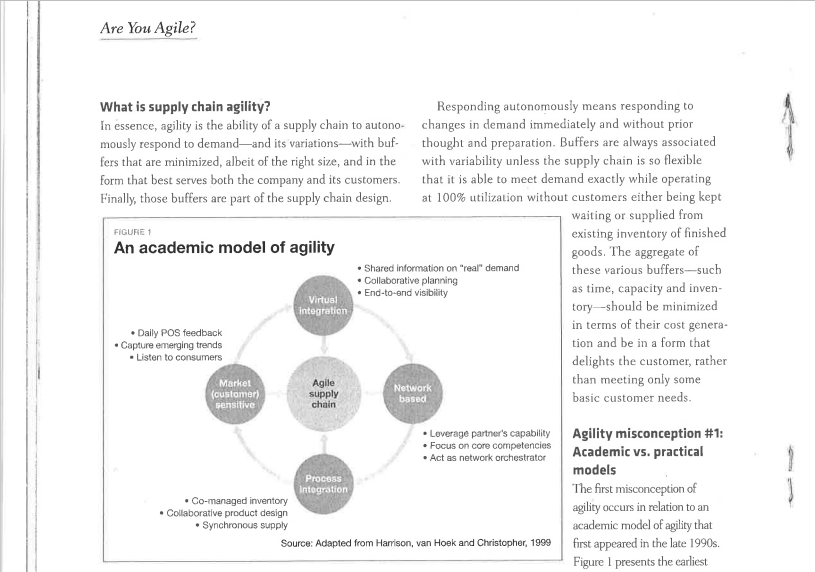

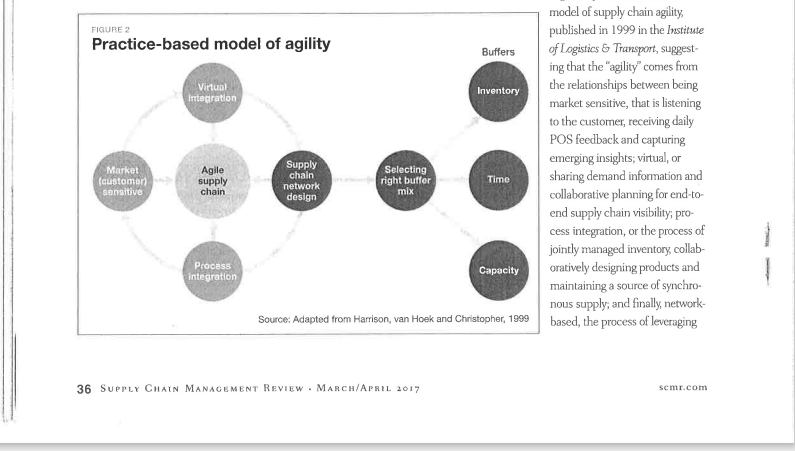

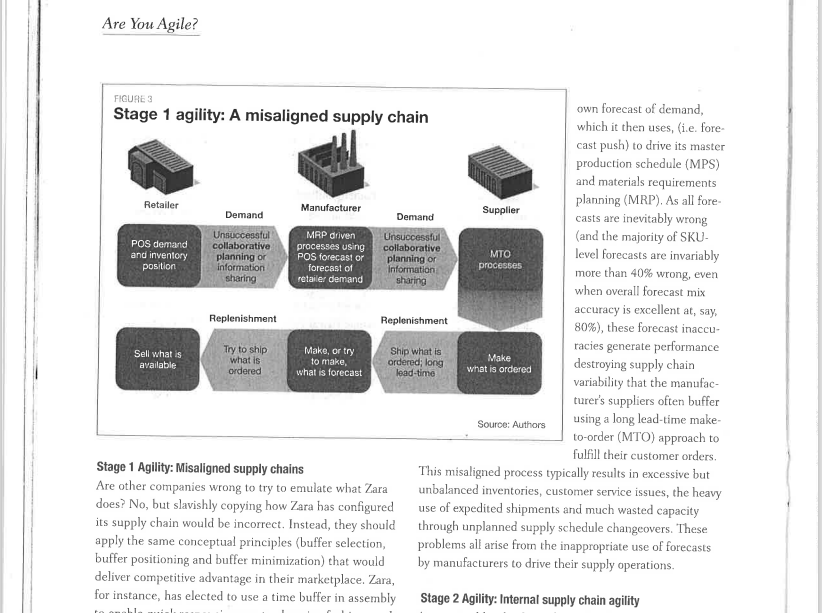

What is supply chain agility? Responding autonomously means responding to In essence, agility is the ability of a supply chain to autono- changes in demand immediately and without prior mously respond to demand- and its variations - with buf- thought and preparation. Buffers are always associated fers that are minimized, albeit of the right size, and in the with variability unless the supply chain is so flexible form that best serves both the company and its customers. that it is able to meet demand exactly while operating Finally, those buffers are part of the supply chain design. at 100\% utilization without customers either being kept waiting or supplied from existing inventory of finished goods. The aggregate of these various buffers -such as time, capacity and inventory-should be minimized in terms of their cost generation and be in a form that delights the customer, rather than meeting only some basic customer needs. Agility misconception \#1: Academic vs. practical models The first misconception of agility occurs in relation to an academic model of agility that first appeared in the late 1990s. Figure 1 presents the earliest model of supply chain agility, published in 1999 in the Institute of Logistics \& Transport, suggesting that the "agility" comes from the relationships between being market sensitive, that is listening to the customer, receiving daily POS feedback and capturing emerging insights; virtual, or sharing demand information and collaborative planning for end-toend supply chain visibility; process integration, or the process of jointly managed inventory, collaboratively designing products and maintaining a source of synchronous supply; and finally, networkbased, the process of leveraging 36 Supply Chain Management Review. March/April 2017 scmr.com the capabilities of partners, focusing on core competencies and from possible low-cost offshore suppliers. An alternative acting as a network orchestrator. While this correctly lays out the example of a time-based buffer would be the concept of concept of agility, it does not expand on its operationalization and engineer-to-order (ETO), which is used for ship building, of the role of structure and functioning of the supply chain, other luxury yachts and oil rigs, where the customer is prepared than it being network-based. to wait for a high level of customization. Figure 2 presents a revised practice-based model of - Capacity buffers. By holding additional capacsupply chain agility, in which the structure of the network ity and maintaining a significant amourt of additional is expanded to include the selection of the right mix of buf- warehouse space, Zara creates the ability to react to fers (such as inventory, time and capacity) that when taken known or unknown surges in demand. The additional together play a significant role in creating the agile capabil- warehouse space allows Zara to rapidly make and hold ity of the supply chain. large amounts of product until it can be shipped to retail It should be noted that the use of buffers is not a new stores. Other examples of capacity buffers are those held concept, but their inclusion explicitly demonstrates that by pharmaceutical companies to enable them to respond agility is also about how buffers are selected, deliberately to competitive bid tenders and, in the service sector, most positioned, used and minimized as a means of delivering fire engines are on stand-by awaiting emergency call out. competitive advantage and the flow of product across the Companies that service strong seasonal demand, or where supply chain. supply is seasonal such as certain foodstuffs like sugar - Inventory buffers. These are kept on-hand within the beet processing and sweet corn canning, also deliberately supply chain to dampen variability in supply and demand hold excess capacity. and to provide a quick response. This type of buffer is used by retailers and manufacturers in sectors such as grocery, Agility misconception \#2: Expediting is not agility consumer packaged goods, life science and home appli- A second and more troubling misconception about agility ances to provide ex-stock service. can happen when manufacturers look at what organiza- - Time buffers. These are based on the principle of post- tions such as Zara, Dell and Cisco have achieved with ponement or assemble-to-order (ATO). Zara's use of 200 their agile supply chains. Many manufacturers mistakenly local sewing suppliers, for example, dramatically reduces think that agility is simply about being able to react quickly the lead-time of assembly and delivery, compared to that and successfully to unexpected demand. They may have some vague understanding that postponement is involved, but they believe that the use of time buffers in conjunc- Demand postponement tion with a postponement-based approach is not relevant 8 emand postponement is nothing new in the sup-__ to them as they follow a make-to-stock (MTS) approach/ Dply chain field. Use of a simple physical sampling strategy. Often under-appreciated is the fact that Zara has approach allows manufacturers to understand which consciously developed a demand-driven supply chain strat- Dly chain field. Use of a simple physical sampling approach allows manufacturers to understand which products are likely to have demand from their custom- ers, or the end consumer. For example, Zara (and Ben- etton before them) issues small samples of its products to its retail stores and then, based on which of these products sell, quickly makes new units to replerish the sold products. By doing this, Zara predominantly makes products that customers want, and saves sig- nificant capital and inventory hoiding costs from mak- ing products that it would then have to significantly discount in order to sell. strategy. Often under-appreciated is the fact that Zara has consciously developed a demand-driven supply chain strategy (and strategy is the key issue here) that is based around the principles of agility. This strategy utilizes elements of demand postponement (small initial commitments of sample products, followed by the quick manufacturing of more of what has sold-see sidebar "Demand postponement"); considerable spare capacity in its distribution centers; and careful positioning of time-based buffers, to create a world-class supply chain with "mind-spinningly supersonic delivery," as it was once described in the New York Times. These give Zara a significant competitive advantage in the apparel industry. scmr.com Supply Chatn Management Revtew - March/April 201737 Are You Agile? FIGUAE 3 Stage 1 agility: A misaligned supply chain own forecast of demand, which it then uses, (i.e. forecast push) to drive its master production schedule (MPS) and materials requirements planning (MRP), As all fore- Are You Agile? FIGUAL 3 Stage 1 Agility: Misaligned supply chains Are other companies wrong to try to emulate what Zara does? No, but slavishly copying how Zara has configured its supply chain would be incorrect. Instead, they should apply the same conceptual principles (buffer selection, buffer positioning and buffer minimization) that would deliver competitive advantage in their marketplace. Zara, for instance, has elected to use a time buffer in assemblyStep by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started