Question

You are the new production manager for a solar panel manufacturing plant. There are panel models in your plant and you want to plan production

You are the new production manager for a solar panel manufacturing plant. There are panel models in your plant and you want to plan production for the next few months. To build each panel model, one consists of raw materials. In addition, one unit of a panel model requires one unit of different types of raw materials. This information is detailed in the binary parameter unm, which is worth 1 if the raw material is used to manufacture the typony panel or otherwise. Each panel is manufactured in one of the production lines. The production capacity where each line is Clt [units / month] in the linear period. On the other hand, due to the limited capacity of your supplier, there is a maximum number of units of raw material that you can buy per period, which is given by the parameter Mmt. Consider that the raw materials purchased in period t are immediately available. Cost-wise, make a unit of the model on the line at Pnl. In addition, there are constant inventory costs throughout the evaluation horizon, where the parameter In indicates the cost of storing a unit of the panel with one period and the parameter H indicates the cost of storing a unit of raw material with one period. Also, initial inventories of panel types, sn, 0, and raw materials, rm, 0 are available. The demand for each panel is esdnt, which indicates the number of typical panels required in the period t. There may be unsatisfied demand at a cost Fn per Type panel not delivered.

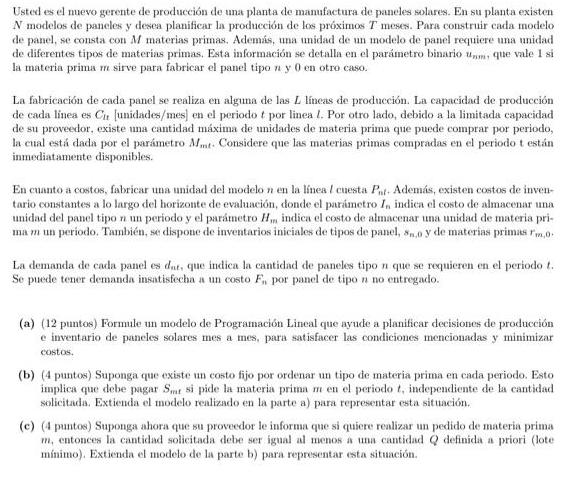

(a) Formulate a Linear Programming model that helps plan production decisions and inventory of solar panels month by month, to satisfy the mentioned conditions and minimize costs.

(b) Suppose there is a fixed cost for ordering one type of raw material in each period. This implies that you must pay Smt if you order the raw material in the period, regardless of the quantity requested. Extend the model made in part a) to represent this situation.

(C) Suppose now that your supplier informs you that if you want to order raw material, then the quantity requested must be equal to at least one quantityQ defined a priori (minimum batch). Extend the model from part b) to represent this situation.

Usted es el nuevo gerente de produccin de una planta de manufactura de paneles solares. En su planta existen N modelos de paneles y desea planificar la produccin de los prximos T meses. Para construir cada modelo de panel, se consta con M materias primas. Adems, una unidad de un modelo de panel requiere una unidad de diferentes tipos de materias primas. Esta informacin se detalla en el parmetro binario um, que vale 1 si la materia prima m sirve para fabricar el panel tipo n y 0 en otro caso. La fabricacin de cada panel se realiza en alguna de las L lneas de produccin. La capacidad de produccin de cada linea es Cu [unidades/mes] en el periodo t por linea L. Por otro lado, debido a la limitada capacidad de su proveedor, existe una cantidad mxima de unidades de materia prima que puede comprar por periodo, la cual est dada por el parmetro Mmt. Considere que las materias primas compradas en el periodo t estn inmediatamente disponibles. En cuanto a costos, fabricar una unidad del modelo n en la lnea / cuesta Pat- Adems, existen costos de inven- tario constantes a lo largo del horizonte de evaluacin, donde el parmetro I, indica el costo de almacenar una unidad del panel tipo n un periodo y el parmetro H, indica el costo de almacenar una unidad de materia pri- mam un periodo. Tambin, se dispone de inventarios iniciales de tipos de panel, so y de materias primas r.0- La demanda de cada panel es dat, que indica la cantidad de paneles tipo n que se requieren en el periodo t. Se puede tener demanda insatisfecha a un costo F, por panel de tipo n no entregado. (a) (12 puntos) Formule un modelo de Programacin Lineal que ayude a planificar decisiones de produccin e inventario de paneles solares mes a mes, para satisfacer las condiciones mencionadas y minimizar costos. (b) (4 puntos) Suponga que existe un costo fijo por ordenar un tipo de materia prima en cada periodo. Esto implica que debe pagar Smr si pide la materia prima m en el periodo t, independiente de la cantidad solicitada. Extienda el modelo realizado en la parte a) para representar esta situacin. (c) (4 puntos) Suponga ahora que su proveedor le informa que si quiere realizar un pedido de materia prima m, entonces la cantidad solicitada debe ser igual al menos a una cantidad Q definida a priori (lote mnimo). Extienda el modelo de la parte b) para representar esta situacin.

Step by Step Solution

3.42 Rating (165 Votes )

There are 3 Steps involved in it

Step: 1

A a Linear Programming Model The linear programming model for planning production decisions and inventory of solar panels month by month can be formul...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started