A company has decided to manufacture a general-purpose smoothing plane, a tool which smoothes and shapes wood.

Question:

A company has decided to manufacture a general-purpose ‘smoothing plane’, a tool which smoothes and shapes wood. Its engineers estimated the time it would take to perform each element in the assembly process. The marketing department also estimated that the likely demand for the new product would be 98,000 units. The marketing department was not totally confident of its forecast; however, ‘a substantial proportion of demand is likely to be export sales, which we find difficult to predict. But whatever demand does turn out to be, we will have to react quickly to meet it. The more we enter these parts of the market, the more we are into impulse buying and the more sales we lose if we don’t supply.’

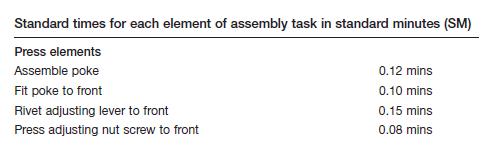

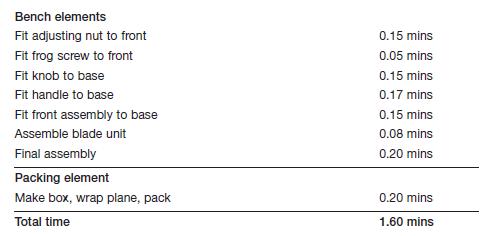

An idea of the assembly task can be gained from the following table which gives the ‘standard time’ for each element of the assembly task.

All elements must be performed sequentially in the order listed.

The standard costing system at the company involves adding a 150 per cent overhead charge to the direct labour cost of manufacturing the product, and the product would retail for the equivalent of around £35 in Europe where most retailers will sell this type of product for about 70–100 per cent more than they buy it from the manufacturer.

● How many people will be needed to assemble this product?

● Design a process for the assembly operation (to include the fly press work) including the tasks to be performed at each part of the system.

● How might the process design need to be adjusted as demand for this and similar products builds up?

Step by Step Answer:

Operations And Process Management Principles And Practice For Strategic Impact

ISBN: 9780273684268

1st Edition

Authors: Nigel Slack, Stuart Chambers, Robert Johnston, Alan Betts