3. The Ace Tool Company is considering implementing the repetitive lot concept in scheduling the firms fabrication

Question:

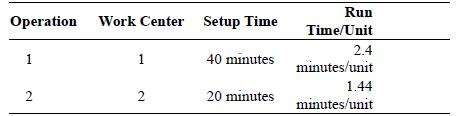

3. The Ace Tool Company is considering implementing the repetitive lot concept in scheduling the firm’s fabrication shop. The production manager selected an example order to use in evaluating benefits and potential costs of this scheduling approach. A transfer batch size of 100 units was suggested for this item. The example order is for a quantity of 1,000 units and has the following routing data:

a. Assuming a single-shift, eight-hour day, five-day week for work centers 1 and 2, prepare a Gantt chart showing the earliest start- and finish-time schedule for this order under a conventional scheduling approach where all items in the order are processed at one time. Do the same when the repetitive lot concept is used. What are the earliest start and finish times for each transfer batch at work center 2, assuming none of the transfer batches are processed together to save setup time?

b. What is the difference in the order-completion times under the two scheduling approaches in part a above?

c. What are the benefits and potential costs of this scheduling approach?

Step by Step Answer:

Manufacturing Planning And Control For Supply Chain Management The CPIM Reference

ISBN: 9781265138516

3rd Edition

Authors: F. Robert Jacobs, William Lee Berry, D. Clay Whybark, Thomas E. Vollmann