An industrial furnace used to heat treat carbon steel is shown in Figure P3.25A. The carbon steel

Question:

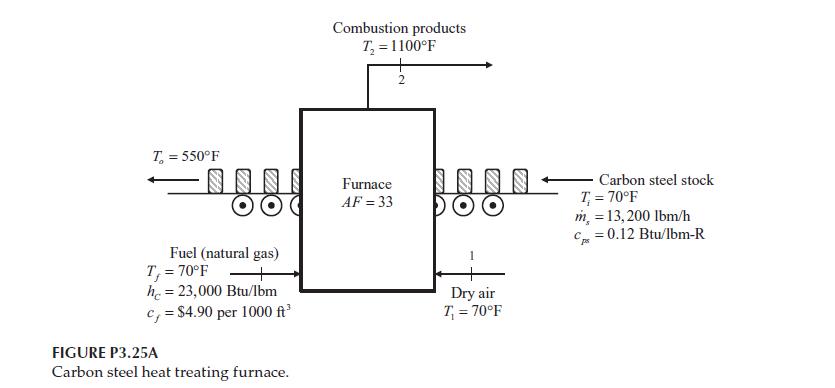

An industrial furnace used to heat treat carbon steel is shown in Figure P3.25A.

The carbon steel stock (cps = 0.12 Btu/lbm-R) passes through the furnace at a rate of 13,200 lbm/h. The steel enters the furnace at 70°F and exits at 550°F. The furnace is fueled by natural gas. The density of the fuel entering the furnace is 0.0456 lbm/ft3 and its heat of combustion is 23,000 Btu/lbm. Dry air for combustion is drawn into the furnace at 70°F. The furnace is operating with a mass-based air-fuel ratio of 33.

Hot combustion products leave the furnace at 1100°F. The pressure throughout the system can be assumed to be 1 atm everywhere.

Determine the,

a. Volumetric flow rate of the fuel (cfm)

b. Cost to run the furnace per day (assuming continuous 24-hour operation) if the industrial cost of natural gas is $4.90 per 1000 ft3

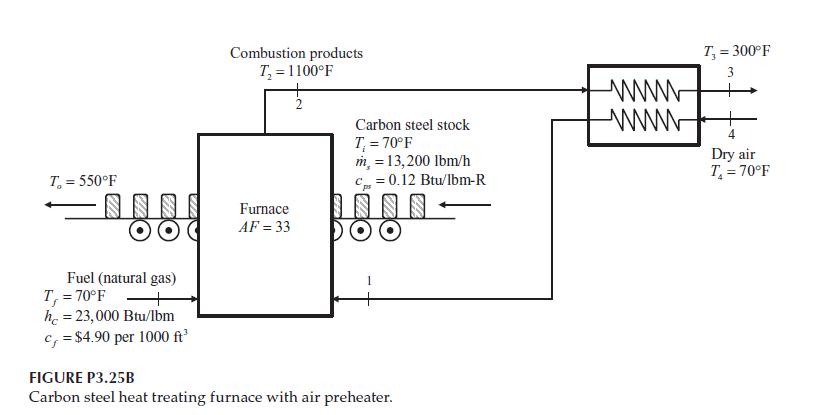

c. Thermal efficiency of the furnace In an effort to increase the thermal efficiency and save money on fuel costs, it is proposed that a counter flow heat exchanger be used to preheat the dry air entering the furnace as shown in Figure P3.25B. The heat exchanger utilizes the hot combustion products as an energy source to preheat the air entering the furnace.

The temperature of the combustion products must be kept well above the dew point temperature to avoid acidic condensation in the heat exchanger. The system designer has specified that this temperature must be no lower than 300°F.

With this heat exchanger added to the system, compute the quantities in (a), (b), and (c) above and compare the results with the values for the furnace without the preheater. In addition, determine,

d. The effectiveness of the heat exchanger for this system

Step by Step Answer:

Thermal Energy Systems Design And Analysis

ISBN: 9781138735897

2nd Edition

Authors: Steven G. Penoncello