Joe Hannibal, senior director of transportation for Young Again Pharmaceuticals (YAP), is gearing up for his companys

Question:

Joe Hannibal, senior director of transportation for Young Again Pharmaceuticals (YAP), is gearing up for his company’s most critical product rollout in more than a decade. YAP has developed a breakthrough liquid suspension that reverses the aging process for anyone over 35 years of age. Available only by prescription, the new product has been dubbed “Twentysomething in a Bottle” by the media. Demand is expected to be very high despite the outlandish price tag of $395 for a month’s supply.

The product is being manufactured in YAP’s Dublin, Ireland, laboratory and will be distributed to major retail pharmacies in the United States and Canada. Hannibal is responsible for selecting the mode and contracting with carriers to deliver the product. He is concerned about the safe and timely delivery of the initial product shipments in April to the retailers’ distribution centers. The product is high value, somewhat fragile, and susceptible to theft. Some product, stolen from the laboratory, has already appeared on auction websites.

In an effort to make effective transportation decisions and minimize YAP’s risks, Hannibal decided to hold a brainstorming session with his logistics team before signing any carrier contracts. The discussion of key risks produced the following list of concerns: • “If shipments are late or incomplete, retailers will penalize us with vendor chargebacks. You know they will hit us with small fines for delivery mistakes.”

• “I’m worried about shipment delays or freight loss from hurricanes in the Atlantic Ocean.”

• “You’ve got to consider temperature sensitivity issues. If the product freezes, we won’t be able to sell it.”

• “I’ve been reading about all the piracy problems experienced by ocean carriers. You know, a 20-foot container of our product has a retail value of nearly $875,000.”

• “I worry about theft of individual cases at ports and while the product is on the road.”

• “We’re looking at border delays and Customs fines if we don’t properly document and mark our freight.”

• “Our brand image will take major damage if the product gets into unauthorized distribution channels due to theft or misdirected deliveries.”

• “The company sustainability push has led to reduced packaging and biodegradable packing materials. If the cartons get wet or bounced around, we’re going to end up with a lot of damaged, unsellable product.”

• “The major U.S. East Coast ports can get very congested during peak shipping season. That will cause delays.”

By the time the meeting was over, Hannibal realized that he needed to spend some time looking into these issues. While he was pretty sure that some problems were remote, Hannibal thought that it would be wise to evaluate each one. His new concern became how to conduct an effective risk assessment.

QUESTIONS

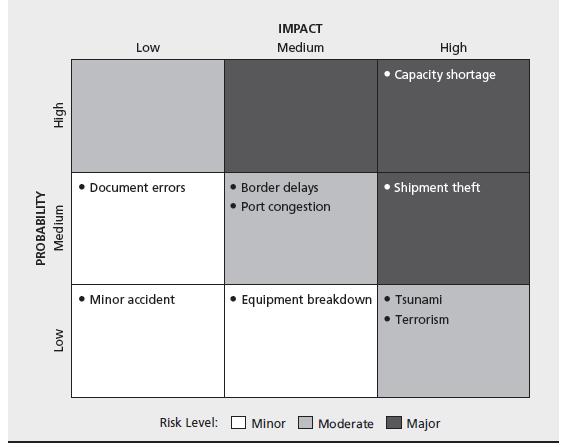

1. Assess the risks identified in the brainstorming session. Create and populate a table similar to Figure 10-2.

Figure 10-2.

2. Based on your answer to Question 1, what are the three primary risks that you believe YAP must address? Why?

3. What do you recommend that YAP do to mitigate each of the three risks identified in Question 2?

4. What should YAP focus on after attempting to mitigate these transportation risks?

Step by Step Answer:

Transportation A Global Supply Chain Perspective

ISBN: 9781337406642

9th Edition

Authors: Robert A. Novack, Brian Gibson, Yoshinori Suzuki, John J. Coyle