Predicting thrust force of a metal drill. In Frontiers in Automobile and Mechanical Engineering (Nov. 2010), a

Question:

Predicting thrust force of a metal drill. In Frontiers in Automobile and Mechanical Engineering (Nov. 2010), a model was developed to predict the thrust force when drilling into a hybrid metal composite. Three variables related to thrust force are spindle speed (revolutions per minute), feed rate (millimeters per minute), and fraction weight of silicon carbide in composite (percentage).

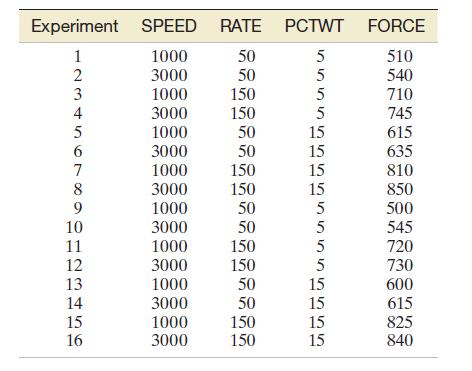

Experimental data were collected by varying these three variables at two levels each: speed (1000 and 3000 rpm), rate (50 and 150 mm/min), and weight (5 and 15 percent).

For each combination of these values, thrust force

(Newtons) of the drill was measured. The data (adapted from information in the article) are listed below.

a. Write the equation of an interaction model for thrust force as a function of spindle speed, feed rate, and fraction weight. Include all possible two-variable interaction terms in the model.

b. Give a function of the model parameters (i.e., the slope) that represent the change in force for every 1% increase in weight when rate is fixed at 50 mm/minute and speed is fixed at 1000 rpm.

c. Give a function of the model parameters (i.e., the slope) that represent the change in force for every 1%

increase in weight when rate is fixed at 150 mm/minute and speed is fixed at 1000 rpm.

d. Fit the interaction model, part

a, to the data using statistical software. Give the least squares prediction equation.

e. Conduct a test to determine whether any of the interaction terms are statistically useful for predicting thrust force. Use a = .05.

Step by Step Answer:

Statistics Plus New Mylab Statistics With Pearson Etext Access Card Package

ISBN: 978-0134090436

13th Edition

Authors: James Mcclave ,Terry Sincich