Question:

Carry out a modified design for an ammonia converter in Example 8.5 consisting of three diabatic reactor bed sections, each of \(2 \mathrm{~m}\) diameter and \(2 \mathrm{~m}\) length (note that the total bed length is the same as before). Assuming the same reactor inlet temperature of \(270^{\circ} \mathrm{C}\), compute the optimum heat duties and effluent temperatures for each bed such that the effluent ammonia mole fraction for the reactor is maximized. Plot the temperature composition trajectory for the modified converter design and compare with the three-bed cold-shot design of Example 8.5.

Data From Example 8.5:-

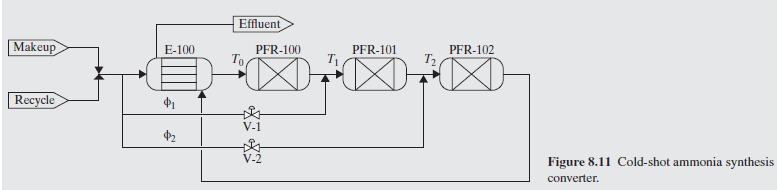

Figure 8.11:-

Transcribed Image Text:

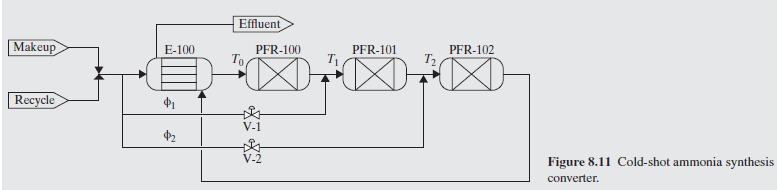

A reactor for the synthesis of ammonia consists of three adiabatic beds, shown in Figure 8.11. As summarized in Table 8.1, the reactor feed consists of two sources, the first of which is a makeup feed stream of 20,000 kmol/hr at 25C and 150 atmospheres containing mainly hydrogen and nitrogen in the stoichiometric molar ratio of 3:1. Since ammonia synthesis gas is produced from naphtha and air, it contains small concentrations of methane from naphtha and argon from air. Both of these species reduce the partial pressures of the reagents, and thus affect the reaction rate. The second feed, which contains larger concentrations of the inert components, is a recycle stream of 40,000 kmol/hr at 25C and 150 atmospheres consisting of unreacted synthesis gas, recovered after removing the ammonia product. The converter consists of three cylindrical, 2-m diameter adiabatic beds packed with catalyst for bed lengths of 1.5 m, 2m, and 2.5m, respectively. The reactor feed is split into three branches, with the first branch being the main feed entering the first bed after being preheated by the hot reactor effluent from the third bed. The second and third branches, with flow fractions (p, and p2, respectively, are controlled by adjusting valves V-1 and V-2. These branches provide "cold-shot" cooling at the first and second bed effluents, respectively. It is desired to optimize the allocation of the bypass fractions to maximize the con- version in the converter.