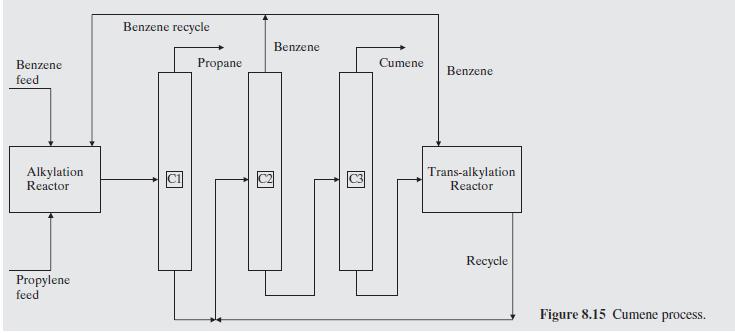

Question: Cumene process with drag (purge) streams. In Example 8.7, a process for producing cumene by the alkylation of benzene with propylene is described. The flowsheet

Cumene process with drag (purge) streams. In Example 8.7, a process for producing cumene by the alkylation of benzene with propylene is described. The flowsheet for the process is given in Figure 8.14.

However, that flowsheet does not provide for the removal of water, ethane, isobutane, \(\mathrm{MCP}, \mathrm{MCH}\) toluene, n-propylbenzene, \(\mathrm{tBB}\), and p-cymene. For their removal, it is proposed to add two drag (purge) streams to the flowsheet: one from the distillate of the benzene recovery column, \(\mathrm{C} 2\), and the other from the bottoms of the cumene recovery column, C3. Also, the flowsheet in Figure 8.14 does not provide for an exit for the heavies produced in the alkylation and trans-alkylation reactors in the event that their amounts are too large to be included in the allowable impurity in the cumene product. Thus, it may be necessary to add a fourth distillation column, \(\mathrm{C} 4\), following \(\mathrm{C} 3\) with the distillate from \(\mathrm{C} 4\) fed to the trans-alkylation reactor and the bottoms from \(\mathrm{C} 4\) being a heavies product. If so, the heavies must not contain more than \(5 \%\) of the DIPBs and lighter entering C4.

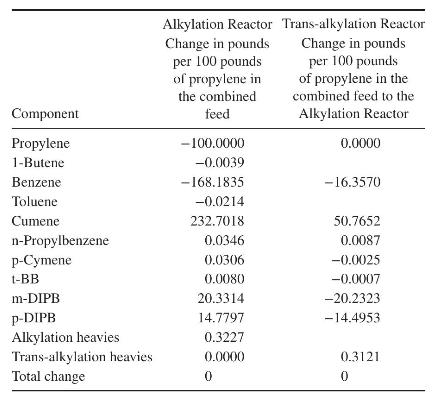

Most of the data for the cumene process is given in Example 8.7. However, missing are the product distributions for the two reactors. These are as follows from laboratory studies:

Using the above data and those in Example 8.7, revise the flowsheet in Figure 8.14 and produce a complete material balance with the component flow rates in \(\mathrm{lbmol} / \mathrm{hr}\) for each stream in your flowsheet. Try to maximize the production of cumene. Be sure to add two drag streams for removal of byproducts and a fourth distillation column if necessary. Compute the overall percent conversion of benzene to cumene and the annual production of cumene in \(\mathrm{lb} / \mathrm{yr}\) if the operating factor is 0.95. If a heavies product is produced, what could it be used for?

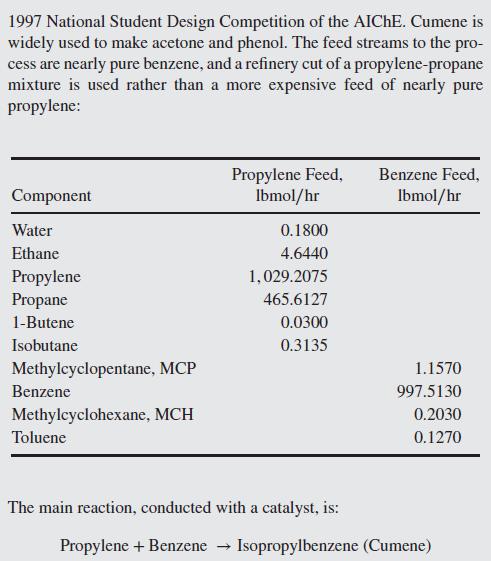

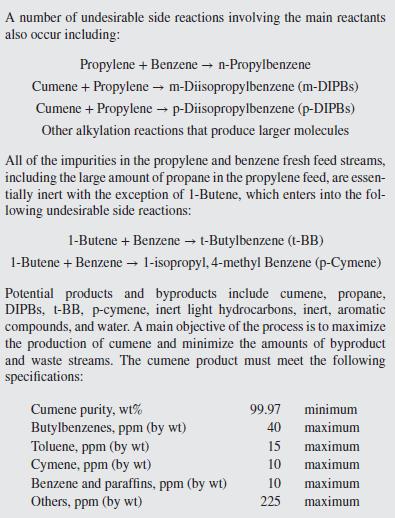

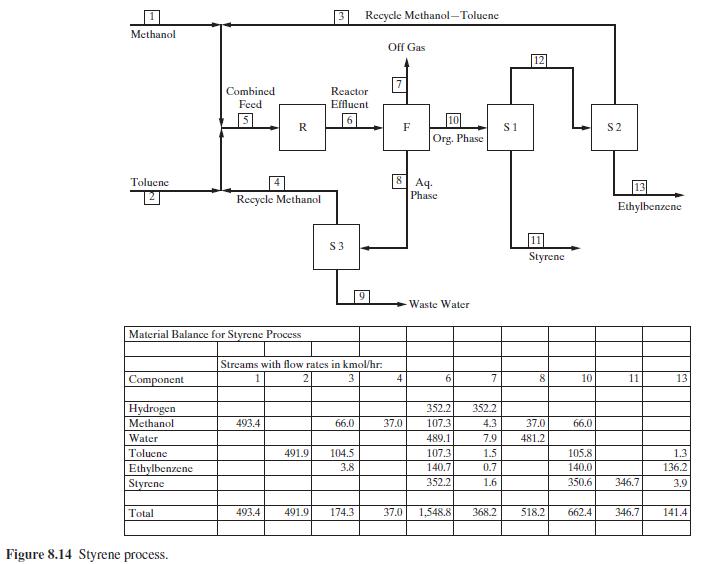

Data From Example 8.7:-

Figure 8.14:-

Alkylation Reactor Change in pounds per 100 pounds of propylene in the combined feed Trans-alkylation Reactor Change in pounds per 100 pounds of propylene in the combined feed to the Alkylation Reactor Component Propylene 1-Butene -100.0000 0.0000 -0.0039 Benzene -168.1835 -16.3570 Toluene -0.0214 Cumene 232.7018 50.7652 n-Propylbenzene 0.0346 0.0087 p-Cymene 0.0306 -0.0025 t-BB 0.0080 -0.0007 m-DIPB 20.3314 -20.2323 p-DIPB Alkylation heavies Trans-alkylation heavies Total change 14.7797 -14.4953 0.3227 0.0000 0.3121 0 0

Step by Step Solution

3.47 Rating (150 Votes )

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts