Statistical process control: percentage defective chart Henke Payne Metal Works uses an investment cast process to produce

Question:

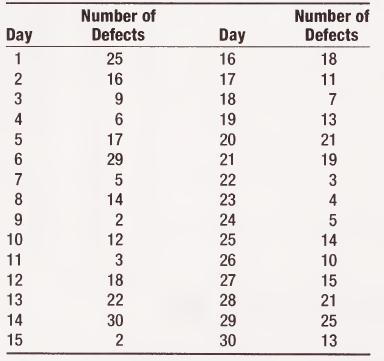

Statistical process control: percentage defective chart Henke Payne Metal Works uses an investment cast process to produce cavity back golf club heads. These perimeter-weighted heads are very well balanced and enable the golfers to stay on target even on off-center hits. The company is very pleased with the reception of this product and is determined to maintain its high quality image. However, not every club head is perfect as even small variations in the mix of alloys causes imperfect casts. In addition, if the molds are not cleaned very carefully or if they begin to wear out, the club heads will not be within specifications. The company expects a certain number of club heads to be defective as long as the daily number of defects appears to be caused by nonrandom problems that the company can control. Lately, the company has been worried that the number of defective units produced is larger than expected. The company accountant and the production engineer decided to inspect 100 items every day for 30 days. Together they collected the following data:

REQUIRED

a. Calculate the proportion defective to the total products inspected.

b. Compute the standard error connected with the p-value calculated above.

c. Establish the control limits for 99% confidence level and identify the samples that are out of statistical control.

d. Set the confidence level at 95% and evaluate the daily samples for possible nonrandom variations.

Step by Step Answer: