A spin coater is used to apply photoresist to a bare silicon wafer. This operation usually occurs

Question:

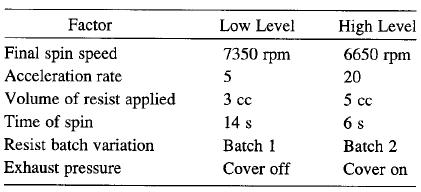

A spin coater is used to apply photoresist to a bare silicon wafer. This operation usually occurs early in the semiconductor manufacturing process, and the average coating thickness and the variability in the coating thickness has an important impact on downstream manufacturing steps. Six variables are used in the experiment. The variables and their high and low levels are as follows:

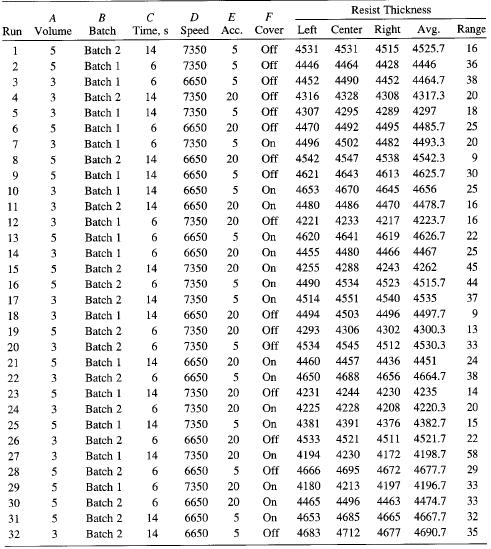

The experimenter decides to use a 26-1 design and to make three readings on resist thick-ness on each test wafer. The data are shown in Table 8-30.

(a) Verify that this is a 26-1 design. Discuss the alias relationships in this design.

(b) What factors appear to affect average resist thickness?

(c) Because the volume of resist applied has little effect on average thickness, does this have any important practical implications for the process engineers?

(d) Project this design into a smaller design involving only the significant factors. Graphically display the results. Does this aid in interpretation?

(e) Use the range of resist thickness as a response variable. Is there any indication that any of these factors affect the variability in resist thickness?

(f) Where would you recommend that the process engineers run the process?

Table 8-10

Step by Step Answer: