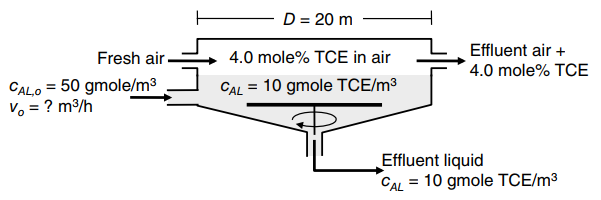

Consider the waste treatment process shown in the figure below. In this process, wastewater containing a dissolved

Question:

a. What is the overall mass-transfer coefficient based on the liquid phase, as KL?

b. What is the flux of TCE from the clarifier liquid surface?

c. Develop a well-mixed, steady material balance model for the process. What is the inlet volumetric flow rate of wastewater, vo (in units of m3/hr) needed to ensure that the liquid effluent TCE concentration is cAL = 10 gmole TCE/m3?

Fantastic news! We've Found the answer you've been seeking!

Step by Step Answer:

Related Book For

Fundamentals Of Momentum Heat And Mass Transfer

ISBN: 9781118947463

6th Edition

Authors: James Welty, Gregory L. Rorrer, David G. Foster

Question Posted: