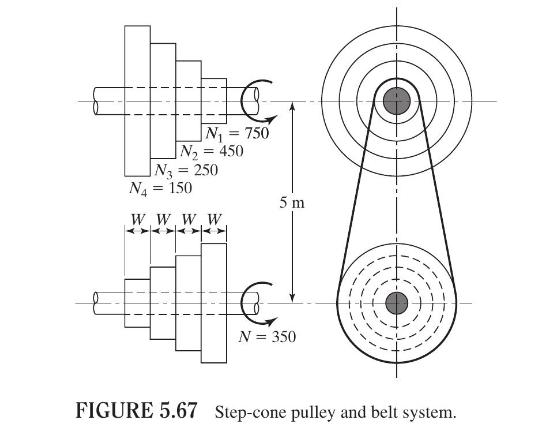

A step-cone pulley with a belt drive (Fig. 5.67) is used to change the cutting speeds in

Question:

A step-cone pulley with a belt drive (Fig. 5.67) is used to change the cutting speeds in a lathe. The speed of the driving shaft is \(350 \mathrm{rpm}\) and the speeds of the output shaft are 150,250, 450 , and \(750 \mathrm{rpm}\). The diameters of the driving and the driven pulleys, corresponding to 150 rpm output speed, are \(250 \mathrm{~mm}\) and \(1000 \mathrm{~mm}\), respectively. The center distance between the shafts is \(5 \mathrm{~m}\). The mass moments of inertia of the driving and driven step cones are 0.1and \(0.2 \mathrm{~kg}-\mathrm{m}^{2}\), respectively. Find the cross-sectional area of the belt to avoid resonance with any of the input/output speeds of the system. Assume the Young's modulus of the belt material as \(10^{10} \mathrm{~N} / \mathrm{m}^{2}\).

Step by Step Answer: