Answered step by step

Verified Expert Solution

Question

1 Approved Answer

1. A company work 50 weeks a year and stores electric motors. Your weekly demand is 20 units a week, the cost per unit

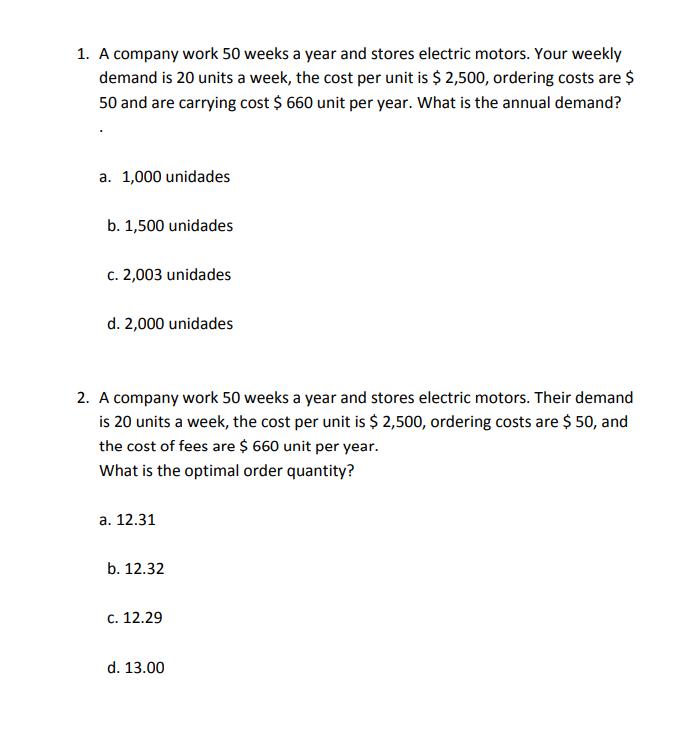

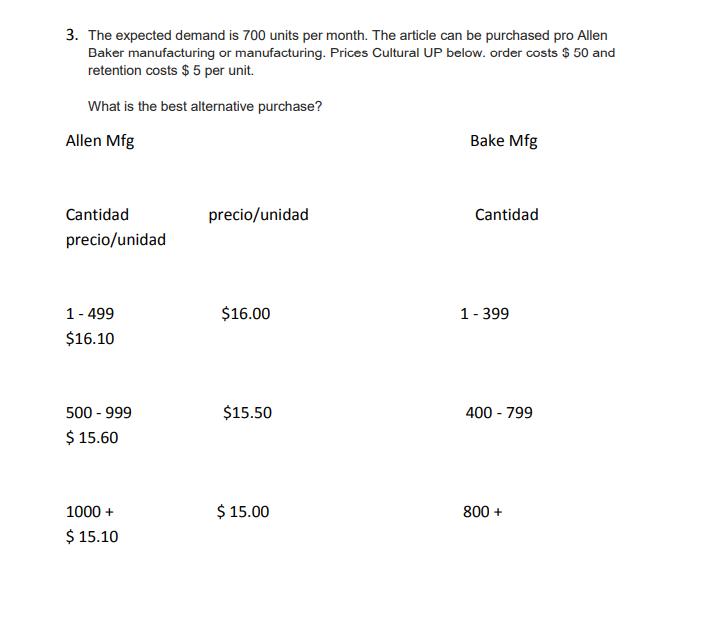

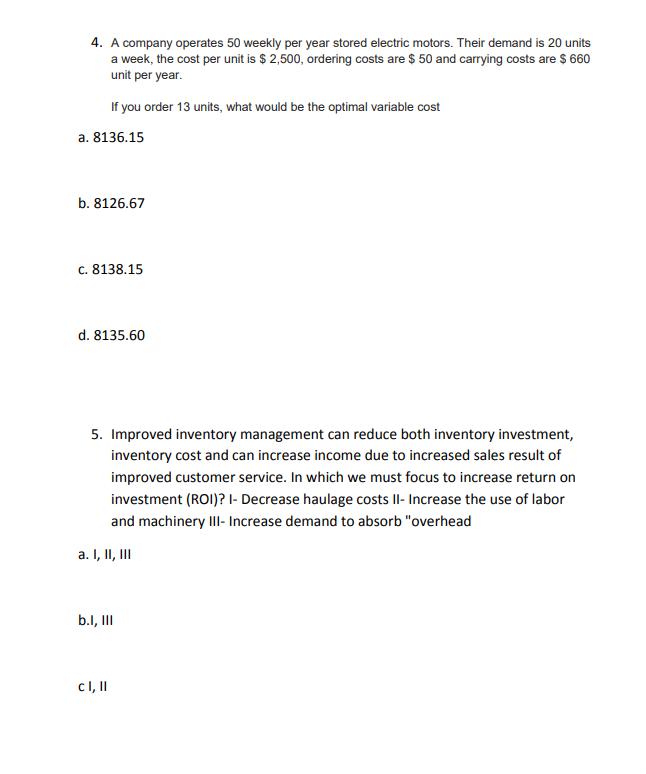

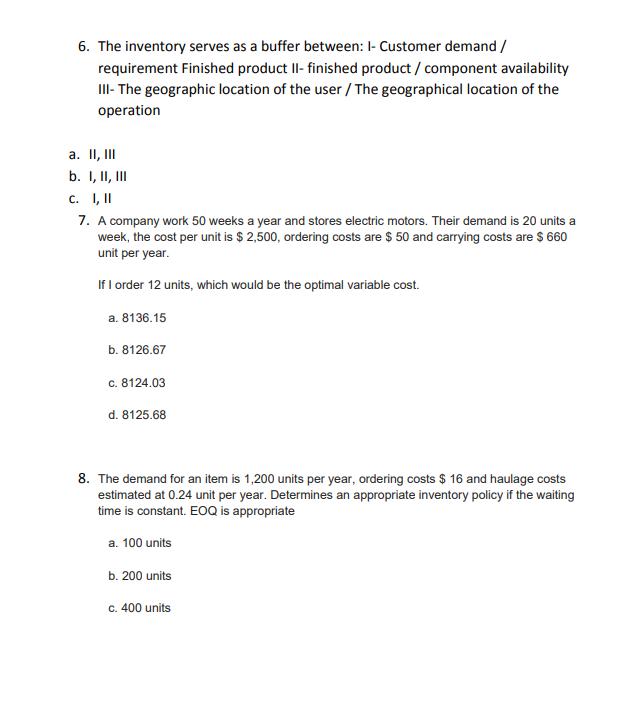

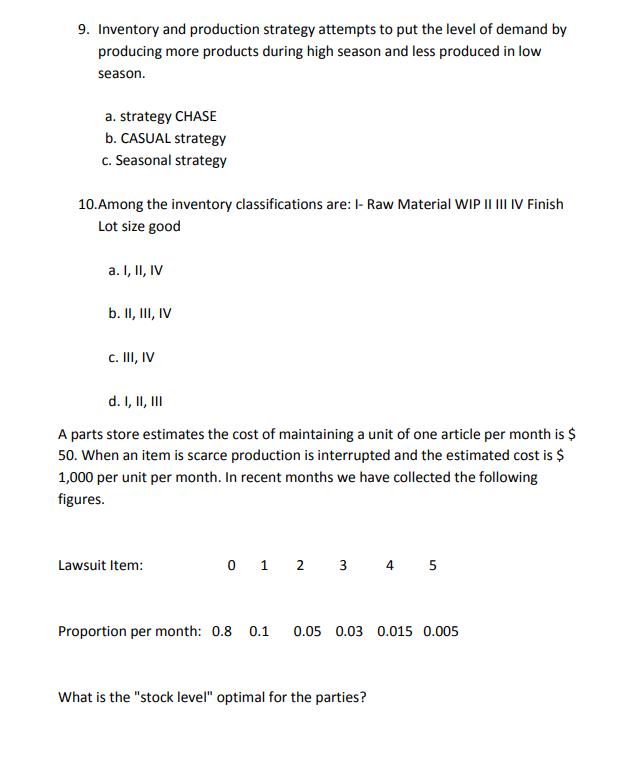

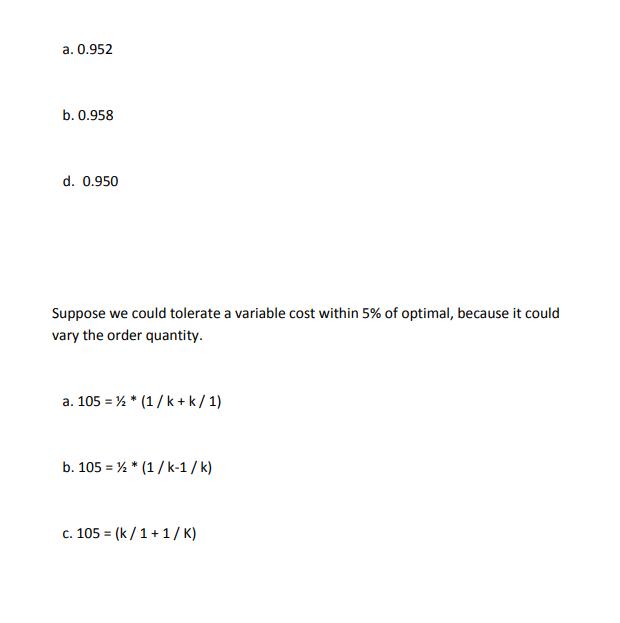

1. A company work 50 weeks a year and stores electric motors. Your weekly demand is 20 units a week, the cost per unit is $ 2,500, ordering costs are $ 50 and are carrying cost $ 660 unit per year. What is the annual demand? a. 1,000 unidades b. 1,500 unidades c. 2,003 unidades d. 2,000 unidades 2. A company work 50 weeks a year and stores electric motors. Their demand is 20 units a week, the cost per unit is $ 2,500, ordering costs are $ 50, and the cost of fees are $ 660 unit per year. What is the optimal order quantity? a. 12.31 b. 12.32 c. 12.29 d. 13.00 3. The expected demand is 700 units per month. The article can be purchased pro Allen Baker manufacturing or manufacturing. Prices Cultural UP below. order costs $ 50 and retention costs $5 per unit. What is the best alternative purchase? Allen Mfg Cantidad precio/unidad 1 - 499 $16.10 500 - 999 $ 15.60 1000 + $ 15.10 precio/unidad $16.00 $15.50 $ 15.00 Bake Mfg Cantidad 1-399 400 - 799 800 + 4. A company operates 50 weekly per year stored electric motors. Their demand is 20 units a week, the cost per unit is $ 2,500, ordering costs are $ 50 and carrying costs are $ 660 unit per year. If you order 13 units, what would be the optimal variable cost a. 8136.15 b. 8126.67 c. 8138.15 d. 8135.60 5. Improved inventory management can reduce both inventory investment, inventory cost and can increase income due to increased sales result of improved customer service. In which we must focus to increase return on investment (ROI)? 1- Decrease haulage costs II- Increase the use of labor and machinery III- Increase demand to absorb "overhead a. I, II, III b.l, Ill CI, II 6. The inventory serves as a buffer between: 1- Customer demand/ requirement Finished product II- finished product/component availability III- The geographic location of the user / The geographical location of the operation a. II, III b. I, II, III c. I, II 7. A company work 50 weeks a year and stores electric motors. Their demand is 20 units a week, the cost per unit is $ 2,500, ordering costs are $ 50 and carrying costs are $ 660 unit per year. If I order 12 units, which would be the optimal variable cost. a. 8136.15 b. 8126.67 c. 8124.03 d. 8125.68 8. The demand for an item is 1,200 units per year, ordering costs $ 16 and haulage costs estimated at 0.24 unit per year. Determines an appropriate inventory policy if the waiting time is constant. EOQ is appropriate a. 100 units b. 200 units c. 400 units 9. Inventory and production strategy attempts to put the level of demand by producing more products during high season and less produced in low season. a. strategy CHASE b. CASUAL strategy c. Seasonal strategy 10. Among the inventory classifications are: I- Raw Material WIP II III IV Finish Lot size good a. I, II, IV b. II, III, IV c. III, IV d. I, II, III A parts store estimates the cost of maintaining a unit of one article per month is $ 50. When an item is scarce production is interrupted and the estimated cost is $ 1,000 per unit per month. In recent months we have collected the following figures. Lawsuit Item: 0 1 2 3 4 5 Proportion per month: 0.8 0.1 0.05 0.03 0.015 0.005 What is the "stock level" optimal for the parties? a. 0.952 b. 0.958 d. 0.950 Suppose we could tolerate a variable cost within 5% of optimal, because it could vary the order quantity. a. 105*(1/k+k/1) b. 105* (1/k-1/k) c. 105 = (k/1 + 1/ K)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started