Question: Due to a product upgrade, two new operations are need for the new version of the part mentioned in Practice Problem 1. Operation 3 is

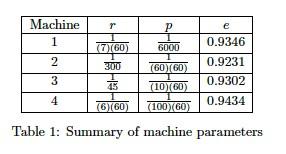

Due to a product upgrade, two new operations are need for the new version of the part mentioned in Practice Problem 1. Operation 3 is a high-precision drilling operation. Machine 3 has a mean time to fail of 10 hours and a mean time to repair of 45 minutes. Machine 4 paints the part pink1. Its mean time to fail is 100 hours and its mean time to repair is 6 hours. The operation times of Machines 3 and 4 are 2 minutes.

When the line is rebuilt there may be buffers between the machines. As the manufacturing systems engineer, your job is to decide whether buffers are needed. (It will also be to decide what size the buffers should be, but that issue is treated in the second part of this course.)

Part 1

What is the maximum production rate that the line can achieve with-out buffers in parts per minute?

Part 2

What is the maximum production rate that the line can achieve with buffers in parts per minute?

Part 3

At what rate does material accumulate in the line if it has infinite buffers in terms of parts per minute?

Machine e 0.9346 (7)(60) 6000 2 0.9231 300 (60)G0) 3 0.9302 45 (10G0) 4 0.9434 (6)(60) (100)(60) Table 1: Summary of machine parameters

Step by Step Solution

3.34 Rating (157 Votes )

There are 3 Steps involved in it

Analysis and Solution Given From the table and text Machines 3 and 4 are new operations Each machines mean time to fail MTTF and mean time to repair MTTR are given The operation time for Machines 3 and 4 is 2 minutes The line is a serial production line with no intermediate storage Part 1 or with infinite buffers Part 2 and 3 1 Compute Availability for Machines 3 and 4 Formulas textAvailability A fractextMTTFtextMTTF textMTTR Machine 3 MTTF 10 hr 600 min MTTR 45 min A3 frac600600 45 frac600645 09302 Machine 4 MTTF 100 hr 6000 min MTTR 6 hr 360 min A4 frac60006000 360 frac60006360 09434 2 Effective Production Rate for Machines 3 and 4 textEffective rate frac1textOperation time times A Operation time 2 min per part Machine 3 r3 frac12 times 09302 04651 text partsmin Machine 4 r4 frac12 times 09434 04717 text partsmin 3 Full Line Analysis From the table for Machines 1 2 Machine 1 r frac1760 frac1420 000238 partsmin p 5000 60 8333 partsmin Use lower Effective r1 000238 times 09346 000222 Machine 2 r 300 6060 3003600 00833 partsmin p 6060 3600 partsmin Effective r2 00833 times 09231 00769 For entire line without buffers Maximum rate is minimum of all machines min000222 00769 04651 04717 000222 text partsmin 4 With Buffers With infinite buffers each machine ... View full answer

Get step-by-step solutions from verified subject matter experts