Answered step by step

Verified Expert Solution

Question

1 Approved Answer

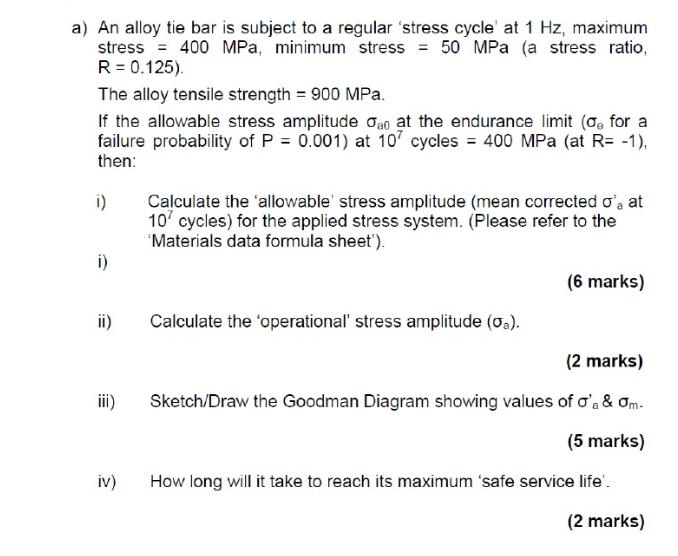

a) An alloy tie bar is subject to a regular 'stress cycle at 1 Hz, maximum stress = 400 MPa, minimum stress = 50

a) An alloy tie bar is subject to a regular 'stress cycle at 1 Hz, maximum stress = 400 MPa, minimum stress = 50 MPa (a stress ratio, R = 0.125). The alloy tensile strength = 900 MPa. If the allowable stress amplitude ao at the endurance limit (0, for a failure probability of P = 0.001) at 107 cycles = 400 MPa (at R= -1), then: i) i) ii) iii) iv) Calculate the 'allowable stress amplitude (mean corrected o'a at 10 cycles) for the applied stress system. (Please refer to the Materials data formula sheet'). Calculate the operational' stress amplitude (0). (6 marks) (2 marks) Sketch/Draw the Goodman Diagram showing values of o', & om- (5 marks) How long will it take to reach its maximum 'safe service life. (2 marks) b) If the Maximum stress is raised to 500 MPa at a stress ratio of R= -1 (assume the endurance and tensile strengths are the initial values), then: ii) How long will the component last until it fails (Please refer to the Materials data formula sheet'). (6 marks) Plot the S-N Graph (on the Log-Log provided) showing the interpolation of 500 MPa Stress amplitude to N Cycles to failure. (4 marks)

Step by Step Solution

There are 3 Steps involved in it

Step: 1

i To calculate the allowable stress amplitude mean corrected a at 10 cycles for the applied stress system we can use the Goodman diagram The Goodman e...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started