Question

a- through MS Excel Solver Add-in how can we solve the production problem for the recommended production quantities. b. What are the objective function coefficient

a- through MS Excel Solver Add-in how can we solve the production problem for the recommended production quantities.

b. What are the objective function coefficient ranges for the six components? Interpret these ranges for the company management.

c. What are the right-hand-side ranges for the resources? Interpret these ranges for company management.

d. If one more hour of grinder time could be made available, how much would it be worth?

pls advise.

==========================================

Listing questions below again which I need support on and they are linked to Linear Programming. I have supplied the data set on my initial message.

a. Formulate and solve Canadian Manufacturings production problem for the recommended production quantities.

b. What are the objective function coefficient ranges for the six components? Interpret these ranges for the company management.

c. What are the right-hand-side ranges for the resources? Interpret these ranges for company management.

d. If one more hour of grinder time could be made available, how much would it be worth?

data

Can you pls write me back if this is still not clear.

---------------------------------

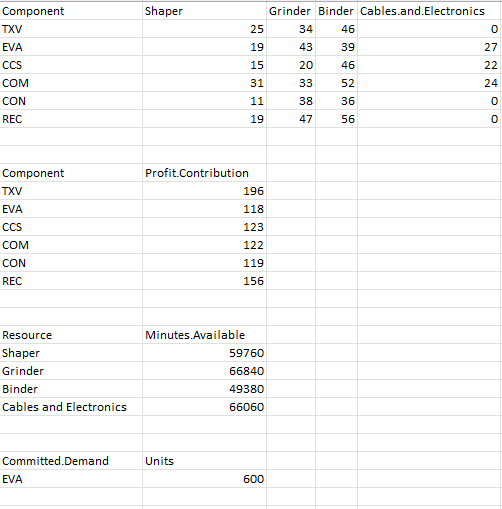

Canadian Manufacturing Ltd makes six components for sale to refrigeration companies. Thermostatic Expansion Valve (TXV): TXV is a device that controls the amount of refrigerant that flows to the evaporator. There you will find the flood back that is essential to maximise the productivity of the evaporator, while stopping the extra liquid refrigerant from going back to the compressor. This device also helps to separate the high-pressure and the low-pressure sides of an air conditioning system. Through the systems liquid line, high pressured liquid refrigerant enters the valve but with the TXVs presence, the amount of liquid refrigerant entering the evaporator will be reduced. Evaporator (EVA): It removes the unwanted heat from the product through liquid refrigerants. The liquid refrigerant must be at a low-pressure. This low-pressure can be determined by two factors one is the heat being absorbed from the product to the liquid refrigerant and the other is the removal of low-pressure vapour by the compressor. Capacity Control System (CCS): It regulates the power and energy consumption, although it can also manage dehumidification or decrease compressor cycling. The on/off cycling of the compressor is the simplest form of capacity control. Compressor (COM): This draws low-temperature and low-pressure vapour from the evaporator through the suction line; the vapour will automatically be compressed once diverted there will also be a rise in the temperature if the vapour is compressed. A compressor can convert low-temperatures to high-temperatures, which can be the cause of an increase in pressure. Through a compressor, heat can be easily released. Condenser (CON): This device can extract heat from the refrigerant. Fans placed above the condenser unit draw air over the condenser coils. The temperature of condensation should range from around -12C to -1C; vapour will be cooled until it becomes a liquid refrigerant again, whereby it will retain some heat. Receiver (REC): As a temporary storage and a surge tank for liquid refrigerant, the receiver acts as a vapour seal. With a primary purpose of preserving the vapour moving down the liquid line to the expansion valve, receivers can be made for both horizontal and vertical installation. 5 of 9 The parameters of this problem are given in the sheet named Production. The components go through four machines/processes with the times in minutes required in each machine/process for each component. The same sheet provides the availability of the shaper, grinder, binder, and cables and electronics in minutes. You will also find the profit contribution of each product and committed demand (demand that must be satisfied) on the same sheet.

a. Formulate and solve Canadian Manufacturings production problem for the recommended production quantities.

b. What are the objective function coefficient ranges for the six components? Interpret these ranges for the company management.

c. What are the right-hand-side ranges for the resources? Interpret these ranges for company management.

d. If one more hour of grinder time could be made available, how much would it be worth?

data

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started