Question: Could you please answer all the options? 8. The data for a single-machine problem of sequencing production work for the seven customer orders arrived at

Could you please answer all the options?

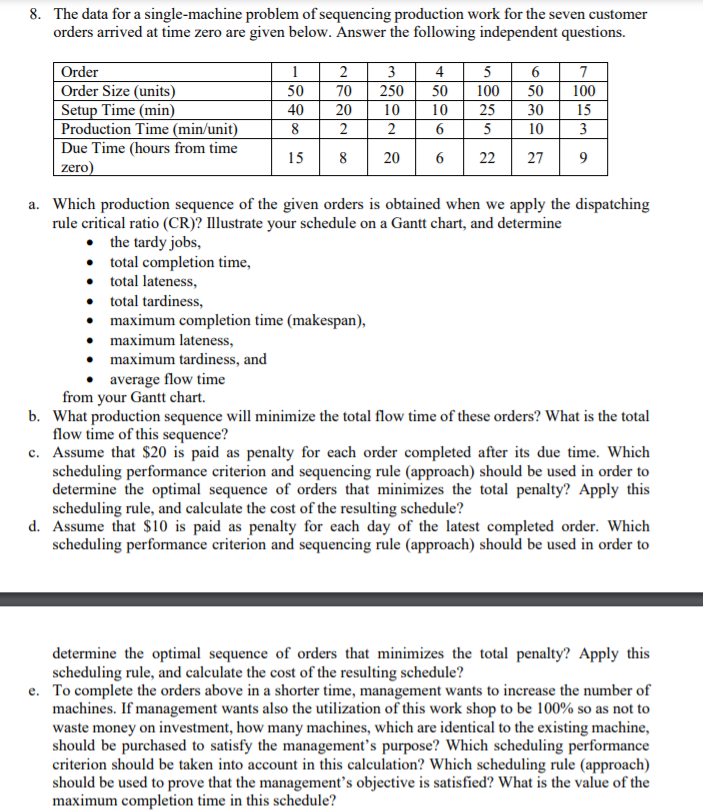

8. The data for a single-machine problem of sequencing production work for the seven customer orders arrived at time zero are given below. Answer the following independent questions. Order Order Size (units) Setup Time (min) Production Time (min/unit) Due Time (hours from time zero) 1 50 40 8 2 70 20 2 3 250 10 2 4 50 10 6 5 100 25 5 67 50 100 30 15 10 3 15 8 20 6 22 27 9 a. Which production sequence of the given orders is obtained when we apply the dispatching rule critical ratio (CR)? Illustrate your schedule on a Gantt chart, and determine the tardy jobs, total completion time, total lateness, total tardiness, maximum completion time (makespan), maximum lateness, maximum tardiness, and average flow time from your Gantt chart. b. What production sequence will minimize the total flow time of these orders? What is the total flow time of this sequence? c. Assume that $20 is paid as penalty for each order completed after its due time. Which scheduling performance criterion and sequencing rule (approach) should be used in order to determine the optimal sequence of orders that minimizes the total penalty? Apply this scheduling rule, and calculate the cost of the resulting schedule? d. Assume that $10 is paid as penalty for each day of the latest completed order. Which scheduling performance criterion and sequencing rule (approach) should be used in order to determine the optimal sequence of orders that minimizes the total penalty? Apply this scheduling rule, and calculate the cost of the resulting schedule? e. To complete the orders above in a shorter time, management wants to increase the number of machines. If management wants also the utilization of this work shop to be 100% so as not to waste money on investment, how many machines, which are identical to the existing machine, should be purchased to satisfy the management's purpose? Which scheduling performance criterion should be taken into account in this calculation? Which scheduling rule (approach) should be used to prove that the management's objective is satisfied? What is the value of the maximum completion time in this schedule? 8. The data for a single-machine problem of sequencing production work for the seven customer orders arrived at time zero are given below. Answer the following independent questions. Order Order Size (units) Setup Time (min) Production Time (min/unit) Due Time (hours from time zero) 1 50 40 8 2 70 20 2 3 250 10 2 4 50 10 6 5 100 25 5 67 50 100 30 15 10 3 15 8 20 6 22 27 9 a. Which production sequence of the given orders is obtained when we apply the dispatching rule critical ratio (CR)? Illustrate your schedule on a Gantt chart, and determine the tardy jobs, total completion time, total lateness, total tardiness, maximum completion time (makespan), maximum lateness, maximum tardiness, and average flow time from your Gantt chart. b. What production sequence will minimize the total flow time of these orders? What is the total flow time of this sequence? c. Assume that $20 is paid as penalty for each order completed after its due time. Which scheduling performance criterion and sequencing rule (approach) should be used in order to determine the optimal sequence of orders that minimizes the total penalty? Apply this scheduling rule, and calculate the cost of the resulting schedule? d. Assume that $10 is paid as penalty for each day of the latest completed order. Which scheduling performance criterion and sequencing rule (approach) should be used in order to determine the optimal sequence of orders that minimizes the total penalty? Apply this scheduling rule, and calculate the cost of the resulting schedule? e. To complete the orders above in a shorter time, management wants to increase the number of machines. If management wants also the utilization of this work shop to be 100% so as not to waste money on investment, how many machines, which are identical to the existing machine, should be purchased to satisfy the management's purpose? Which scheduling performance criterion should be taken into account in this calculation? Which scheduling rule (approach) should be used to prove that the management's objective is satisfied? What is the value of the maximum completion time in this schedule

Step by Step Solution

There are 3 Steps involved in it

Get step-by-step solutions from verified subject matter experts