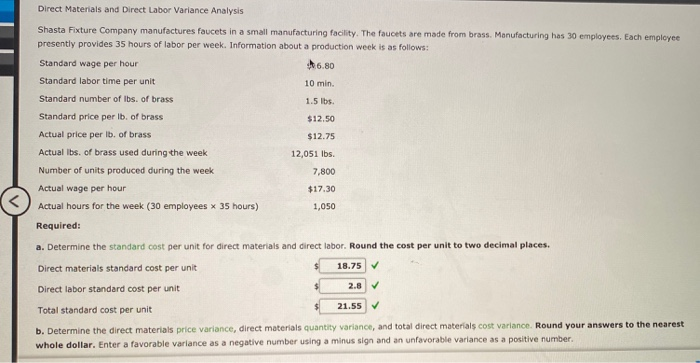

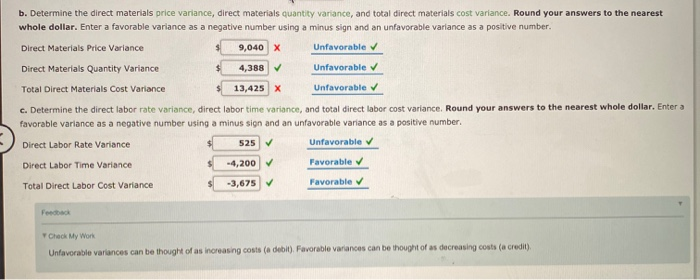

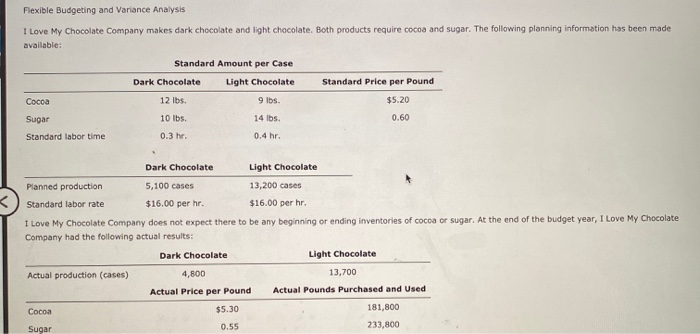

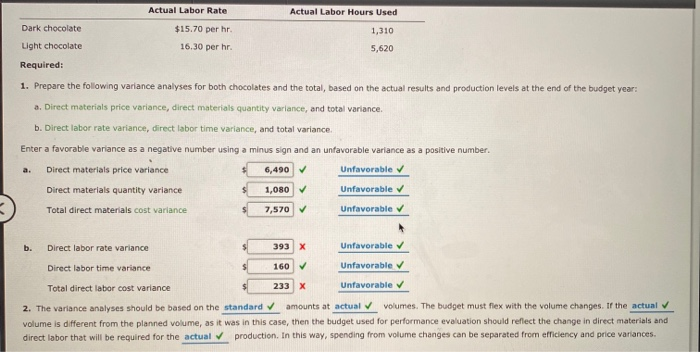

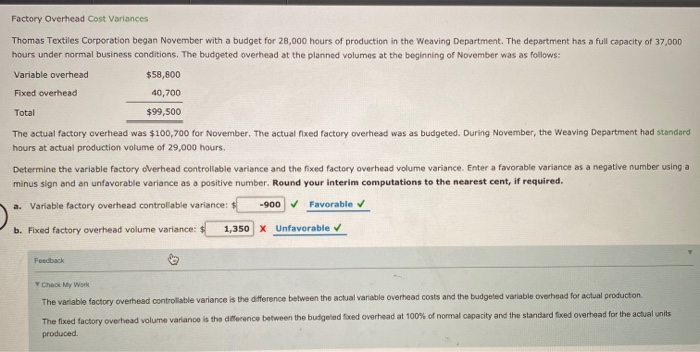

Direct Materials and Direct Labor Variance Analysis Shasta Fixture Company manufactures Faucets in a small manufacturing facility. The faucets are made from brass. Manufacturing has 30 employees. Each employee presently provides 35 hours of labor per week. Information about a production week is as follows: Standard wage per hour 6.80 Standard labor time per unit 10 min. Standard number of lbs. of brass 1.5 lbs. Standard price per lb. of brass $12.50 Actual price per Ib. of brass $12.75 Actual lbs. of brass used during the week 12,051 lbs. Number of units produced during the week 7,800 Actual wage per hour $17.30 Actual hours for the week (30 employees x 35 hours) 1,050 Required: a. Determine the standard cost per unit for direct materials and direct labor. Round the cost per unit to two decimal places. Direct materials standard cost per unit 18.75 Direct labor standard cost per unit 2.8 Total standard cost per unit 21.55 b. Determine the direct materials price variance, direct materials quantity variance, and total direct materials cost variance. Round your answers to the nearest whole dollar. Enter a favorable variance as a negative number using a minus sign and an unfavorable variance as a positive number. b. Determine the direct materials price variance, direct materials quantity variance, and total direct materials cost variance. Round your answers to the nearest whole dollar. Enter a favorable variance as a negative number using a minus sign and an unfavorable variance as a positive number. Direct Materials Price Variance 9,040 X Unfavorable Direct Materials Quantity Variance 4,388 Unfavorable Total Direct Materials Cost Variance 13,425 X Unfavorable c. Determine the direct labor rate variance, direct labor time variance, and total direct labor cost variance. Round your answers to the nearest whole dollar. Enter a favorable variance as a negative number using a minus sign and an unfavorable variance as a positive number. Direct Labor Rate Variance 525 Unfavorable Direct Labor Time Variance -4,200 Favorable Total Direct Labor Cost Variance -3,675 Favorable Check My Work Unfavorable variances can be thought of as increasing costs (a debit). Favorable variances can be thought of as decreasing costs (a credit) Flexible Budgeting and Variance Analysis I Love My Chocolate Company makes dark chocolate and light chocolate. Both products require cocoa and sugar. The following planning information has been made available: Standard Price per Pound Cocoa Standard Amount per Case Dark Chocolate Light Chocolate 12 lbs. 9 lbs. 10 lbs. 14 lbs. 0.3 hr. 0.4 hr. $5.20 0.60 Sugar Standard labor time Dark Chocolate Light Chocolate Planned production 5,100 cases 13,200 cases Standard labor rate $16.00 per hr. $16.00 per hr. I Love My Chocolate Company does not expect there to be any beginning or ending inventories of cocoa or sugar. At the end of the budget year, I Love My Chocolate Company had the following actual results: Dark Chocolate Light Chocolate Actual production (cases) 4,800 13,700 Actual Price per Pound Actual Pounds Purchased and Used Cocoa $5.30 181,800 0.55 233,800 Sugar Actual Labor Rate $15.70 per hr Dark chocolate Light chocolate Actual Labor Hours Used 1,310 5,620 16.30 per hr. Required: 1. Prepare the following variance analyses for both chocolates and the total, based on the actual results and production levels at the end of the budget year: a. Direct materials price variance, direct materials quantity variance, and total variance. b. Direct labor rate variance, direct labor time variance, and total variance, Enter a favorable variance as a negative number using a minus sign and an unfavorable variance as a positive number. Direct materials price variance 6,490 Unfavorable Direct materials quantity variance 1,080 Unfavorable Total direct materials cost variance 7,570 Unfavorable b. Direct labor rate variance 393 X Unfavorable Direct labor time variance 160 Unfavorable Total direct labor cost variance 233 X Unfavorable 2. The variance analyses should be based on the standard amounts at actual volumes. The budget must flex with the volume changes. If the actual volume is different from the planned volume, as it was in this case, then the budget used for performance evaluation should reflect the change in direct materials and direct labor that will be required for the actual production. In this way, spending from volume changes can be separated from efficiency and price variances. Factory Overhead Cost Variances Thomas Textiles Corporation began November with a budget for 28,000 hours of production in the Weaving Department. The department has a full capacity of 37,000 hours under normal business conditions. The budgeted overhead at the planned volumes at the beginning of November was as follows: Variable overhead $58,800 Fixed overhead 40,700 Total $99,500 The actual factory overhead was $100,700 for November. The actual fixed factory overhead was as budgeted. During November, the Weaving Department had standard hours at actual production volume of 29,000 hours. Determine the variable factory overhead controllable variance and the fixed factory overhead volume variance. Enter a favorable variance as a negative number using a minus sign and an unfavorable variance as a positive number. Round your interim computations to the nearest cent, if required. a. Variable factory overhead controllable variance: $ -900 Favorable b. Fixed factory overhead volume variance: $ 1,350 X Unfavorable Feedback Check My Work The variable factory overhead controllable variance is the difference between the actual variable overhead costs and the budgeted variable overhead for actual producton The fixed factory overhead volume variance is the difference between the budgeted faced overhead at 100% of normal capacity and the standard foxed overhead for the actual units produced