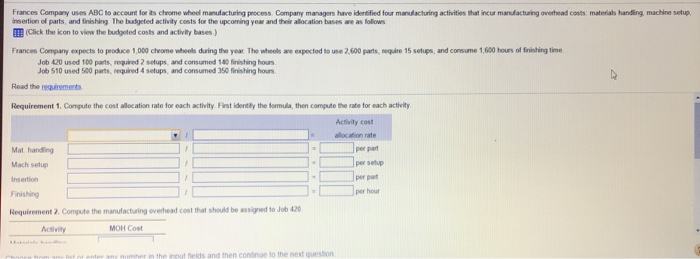

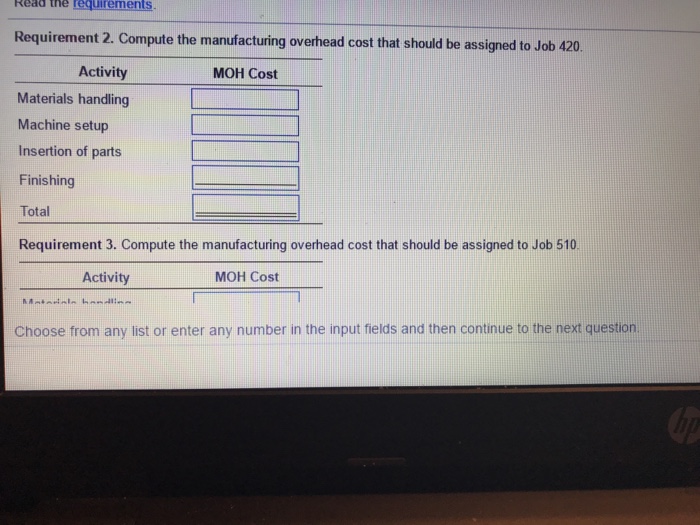

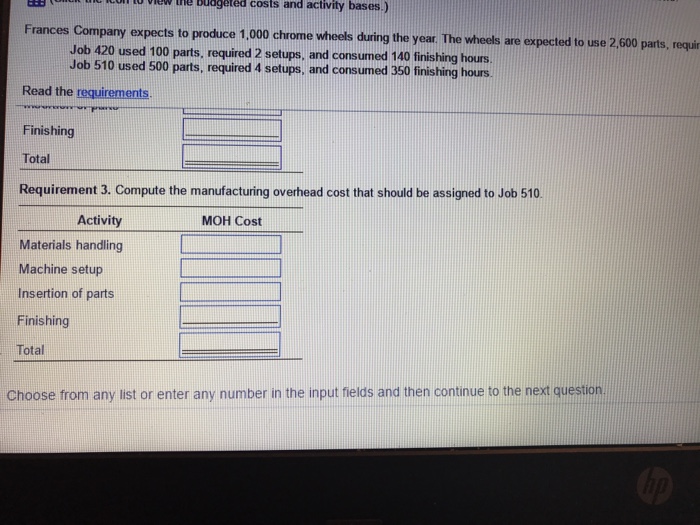

Frances Company uses ABC to account for its chrome wheel manufacturing process. Company managers have identified four manufacturing activities that incur mandfacturing ovethead conts: materiabs handing, machine setup insertion of parts, and finishing The budgeted activity costs for the upcoming year and their allocation bases are as folows (Click the icon to view the budgeted costs and activity bases ) Frances Company expects to produce 1,000 cheome wheols duing the year The wheols ae expected to use 2,600 parts, nequire 15 setups, and consume 1,600 hours of finishing time Job 420 used 100 parts, required 2 setups, and consumed 100 finishing hours Job 510 used 500 parts, required 4 setups, and consumed 350 finishing hours Read the requirements Requirement 1. Compute the cost allocation rate for each activity First idenity the formula, then compute the rate for each activity Activity cost Mat handing Mach setup Insertion Finishing Requirement 2 Compute the manufacturing everhead cost that should be assigned to Job 420 per pan per setup per pat -per hour Activity MOH Cost om a Iut o enter any number in the inout felds and then contnue to the next question Frances Company uses ABC to account for its chrome wheel manufacturing process. Company managers have identified four manufacturing activities that incur mandfacturing ovethead conts: materiabs handing, machine setup insertion of parts, and finishing The budgeted activity costs for the upcoming year and their allocation bases are as folows (Click the icon to view the budgeted costs and activity bases ) Frances Company expects to produce 1,000 cheome wheols duing the year The wheols ae expected to use 2,600 parts, nequire 15 setups, and consume 1,600 hours of finishing time Job 420 used 100 parts, required 2 setups, and consumed 100 finishing hours Job 510 used 500 parts, required 4 setups, and consumed 350 finishing hours Read the requirements Requirement 1. Compute the cost allocation rate for each activity First idenity the formula, then compute the rate for each activity Activity cost Mat handing Mach setup Insertion Finishing Requirement 2 Compute the manufacturing everhead cost that should be assigned to Job 420 per pan per setup per pat -per hour Activity MOH Cost om a Iut o enter any number in the inout felds and then contnue to the next