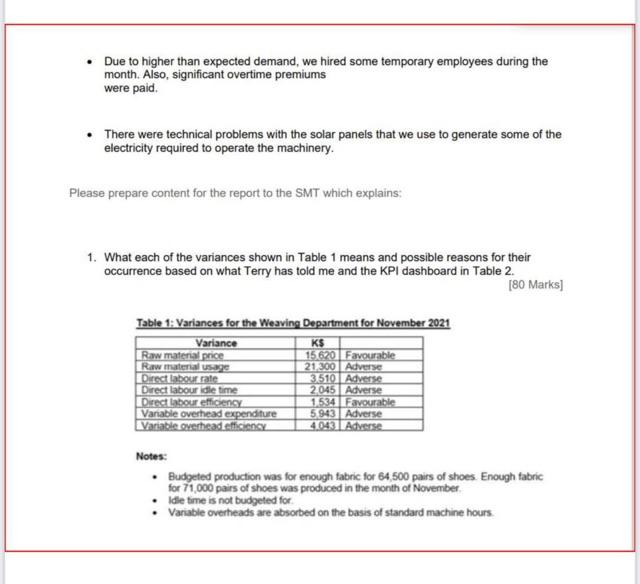

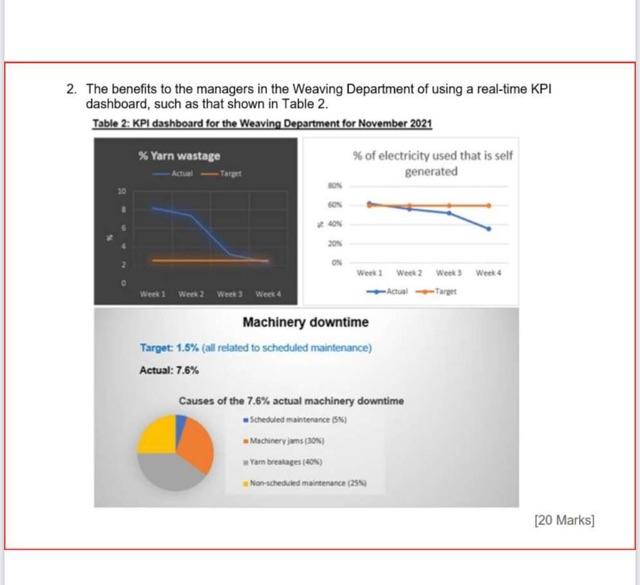

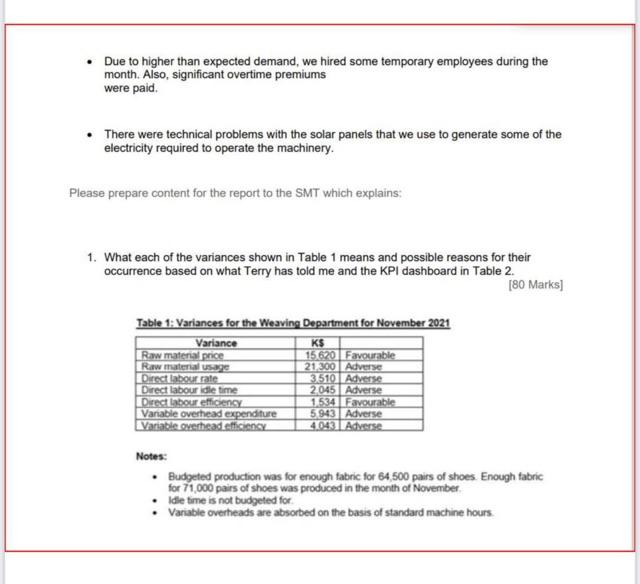

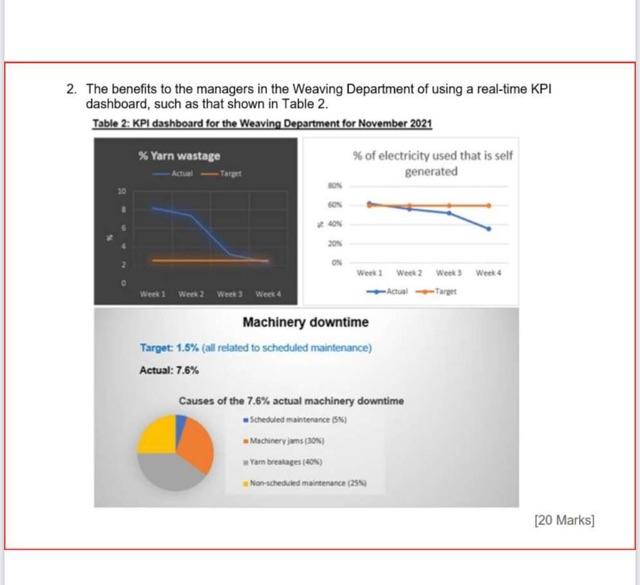

From: Ben Numa, Finance Manager To: Finance Officer Subject: Performance of Weaving Department in November The Senior Management Team (SMT) has asked for a report on the performance of the Weaving Department. Attached in Table 1 are some of the production variances for the Weaving Department for November. We have been developing a real time Key Performance Indicator (KPI) dashboard for production. It isn't yet available in real time, but I have prepared a dashboard to cover the same period as the variances (Table 2 attached). I have spoken to Terry Amos, Head of Production, who told me that: - In October, Oleg Scragg. Production Director, signed up new supplier for some of the yarn used in production. The yarn from this - supplier was used in production from the start of November. - There was significant weaving machinery downtime in November as shown in the KPI dashboard. Some scheduled maintenance of the machinery was delayed in the month due to employee shortages in the Maintenance Department. - Due to higher than expected demand, we hired some temporary employees during the month. Also, significant overtime premiums were paid. - There were technical problems with the solar panels that we use to generate some of the electricity required to operate the machinery. Please prepare content for the report to the SMT which explains: 1. What each of the variances shown in Table 1 means and possible reasons for their occurrence based on what Terry has told me and the KPI dashboard in Table 2. [80 Marks] Table 1: Variances for the Weaving Department for November 2021 Notes: - Budgeted production was for enough fabric for 64,500 pairs of shoes. Enough fabric for 71,000 pairs of shoes was produced in the month of November. - Idle time is not budgeted for. - Variable overheads are absorbed on the basis of standard machine hours. 2. The benefits to the managers in the Weaving Department of using a real-time KPI dashboard, such as that shown in Table 2. Table 2: KPl dashboard for the Weaving Department for November 2021 Machinery downtime Target: 1.5\% (all related to scheduled maintenance) Actual: 7.6% Causes of the 7.6% actual machinery downtime - Scteduled mantenance (V) - Machineryjans [306] * Tan toeatages (40N) Hohtheduled mairtenance (25*) From: Ben Numa, Finance Manager To: Finance Officer Subject: Performance of Weaving Department in November The Senior Management Team (SMT) has asked for a report on the performance of the Weaving Department. Attached in Table 1 are some of the production variances for the Weaving Department for November. We have been developing a real time Key Performance Indicator (KPI) dashboard for production. It isn't yet available in real time, but I have prepared a dashboard to cover the same period as the variances (Table 2 attached). I have spoken to Terry Amos, Head of Production, who told me that: - In October, Oleg Scragg. Production Director, signed up new supplier for some of the yarn used in production. The yarn from this - supplier was used in production from the start of November. - There was significant weaving machinery downtime in November as shown in the KPI dashboard. Some scheduled maintenance of the machinery was delayed in the month due to employee shortages in the Maintenance Department. - Due to higher than expected demand, we hired some temporary employees during the month. Also, significant overtime premiums were paid. - There were technical problems with the solar panels that we use to generate some of the electricity required to operate the machinery. Please prepare content for the report to the SMT which explains: 1. What each of the variances shown in Table 1 means and possible reasons for their occurrence based on what Terry has told me and the KPI dashboard in Table 2. [80 Marks] Table 1: Variances for the Weaving Department for November 2021 Notes: - Budgeted production was for enough fabric for 64,500 pairs of shoes. Enough fabric for 71,000 pairs of shoes was produced in the month of November. - Idle time is not budgeted for. - Variable overheads are absorbed on the basis of standard machine hours. 2. The benefits to the managers in the Weaving Department of using a real-time KPI dashboard, such as that shown in Table 2. Table 2: KPl dashboard for the Weaving Department for November 2021 Machinery downtime Target: 1.5\% (all related to scheduled maintenance) Actual: 7.6% Causes of the 7.6% actual machinery downtime - Scteduled mantenance (V) - Machineryjans [306] * Tan toeatages (40N) Hohtheduled mairtenance (25*)