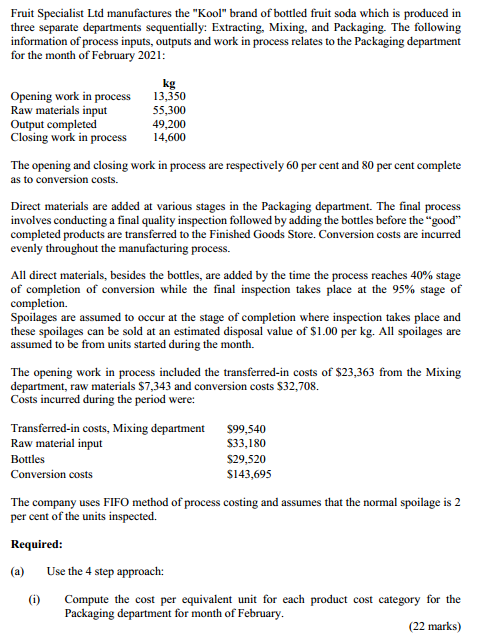

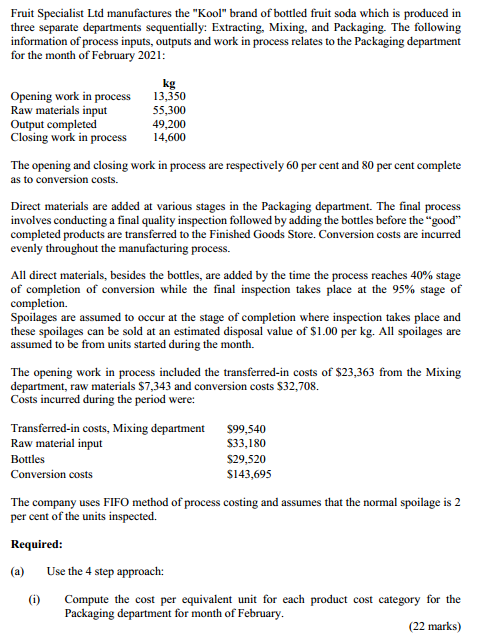

Fruit Specialist Ltd manufactures the "Kool" brand of bottled fruit soda which is produced in three separate departments sequentially: Extracting, Mixing, and Packaging. The following information of process inputs, outputs and work in process relates to the Packaging department for the month of February 2021: kg Opening work in process 13,350 Raw materials input 55,300 Output completed 49,200 Closing work in process 14,600 The opening and closing work in process are respectively 60 per cent and 80 per cent complete as to conversion costs. Direct materials are added at various stages in the Packaging department. The final process involves conducting a final quality inspection followed by adding the bottles before the "good" completed products are transferred to the Finished Goods Store. Conversion costs are incurred evenly throughout the manufacturing process. All direct materials, besides the bottles, are added by the time the process reaches 40% stage of completion of conversion while the final inspection takes place at the 95% stage of completion. Spoilages are assumed to occur at the stage of completion where inspection takes place and these spoilages can be sold at an estimated disposal value of $1.00 per kg. All spoilages are assumed to be from units started during the month. The opening work in process included the transferred-in costs of $23,363 from the Mixing department, raw materials $7,343 and conversion costs $32,708. Costs incurred during the period were: Transferred-in costs, Mixing department $99,540 Raw material input $33,180 Bottles $29,520 Conversion costs $143,695 The company uses FIFO method of process costing and assumes that the normal spoilage is 2 per cent of the units inspected. Required: (a) Use the 4 step approach: (i) Compute the cost per equivalent unit for each product cost category for the Packaging department for month of February. (22 marks) Fruit Specialist Ltd manufactures the "Kool" brand of bottled fruit soda which is produced in three separate departments sequentially: Extracting, Mixing, and Packaging. The following information of process inputs, outputs and work in process relates to the Packaging department for the month of February 2021: kg Opening work in process 13,350 Raw materials input 55,300 Output completed 49,200 Closing work in process 14,600 The opening and closing work in process are respectively 60 per cent and 80 per cent complete as to conversion costs. Direct materials are added at various stages in the Packaging department. The final process involves conducting a final quality inspection followed by adding the bottles before the "good" completed products are transferred to the Finished Goods Store. Conversion costs are incurred evenly throughout the manufacturing process. All direct materials, besides the bottles, are added by the time the process reaches 40% stage of completion of conversion while the final inspection takes place at the 95% stage of completion. Spoilages are assumed to occur at the stage of completion where inspection takes place and these spoilages can be sold at an estimated disposal value of $1.00 per kg. All spoilages are assumed to be from units started during the month. The opening work in process included the transferred-in costs of $23,363 from the Mixing department, raw materials $7,343 and conversion costs $32,708. Costs incurred during the period were: Transferred-in costs, Mixing department $99,540 Raw material input $33,180 Bottles $29,520 Conversion costs $143,695 The company uses FIFO method of process costing and assumes that the normal spoilage is 2 per cent of the units inspected. Required: (a) Use the 4 step approach: (i) Compute the cost per equivalent unit for each product cost category for the Packaging department for month of February. (22 marks)