Answered step by step

Verified Expert Solution

Question

1 Approved Answer

Gas scrubbing, also called gas absorption is a process that brings gas streams into contact with liquid and allows some of the gas components

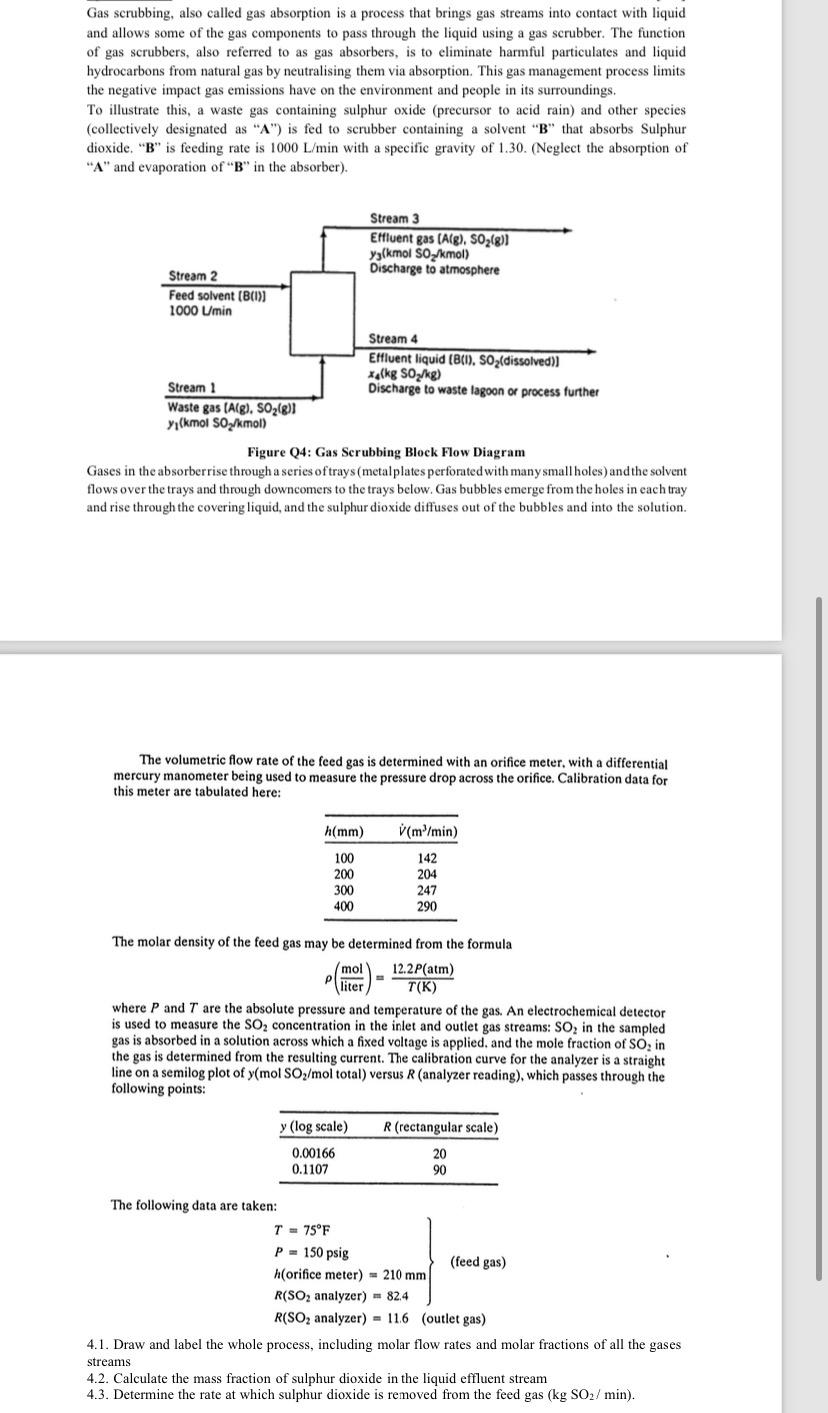

Gas scrubbing, also called gas absorption is a process that brings gas streams into contact with liquid and allows some of the gas components to pass through the liquid using a gas scrubber. The function of gas scrubbers, also referred to as gas absorbers, is to eliminate harmful particulates and liquid hydrocarbons from natural gas by neutralising them via absorption. This gas management process limits the negative impact gas emissions have on the environment and people in its surroundings. To illustrate this, a waste gas containing sulphur oxide (precursor to acid rain) and other species (collectively designated as "A") is fed to scrubber containing a solvent "B" that absorbs Sulphur dioxide. "B" is feeding rate is 1000 L/min with a specific gravity of 1.30. (Neglect the absorption of "A" and evaporation of "B" in the absorber). Stream 2 Feed solvent (B(1)] 1000 L/min Stream 3 Effluent gas (A(g), SO2(g)] ya(kmol SO2/kmol) Discharge to atmosphere Stream 1 Waste gas (A(g), SO2(g)] y(kmol So/kmol) Stream 4 Effluent liquid (B(1), SO(dissolved)] x(kg SO/kg) Discharge to waste lagoon or process further Figure Q4: Gas Scrubbing Block Flow Diagram Gases in the absorberrise through a series of trays (metalplates perforated with many small holes) and the solvent flows over the trays and through downcomers to the trays below. Gas bubbles emerge from the holes in each tray and rise through the covering liquid, and the sulphur dioxide diffuses out of the bubbles and into the solution. The volumetric flow rate of the feed gas is determined with an orifice meter, with a differential mercury manometer being used to measure the pressure drop across the orifice. Calibration data for this meter are tabulated here: h(mm) V(m/min) 100 142 200 204 300 247 400 290 The molar density of the feed gas may be determined from the formula mol liter 12.2P(atm) T(K) where P and T are the absolute pressure and temperature of the gas. An electrochemical detector is used to measure the SO2 concentration in the inlet and outlet gas streams: SO; in the sampled gas is absorbed in a solution across which a fixed voltage is applied. and the mole fraction of SO; in the gas is determined from the resulting current. The calibration curve for the analyzer is a straight line on a semilog plot of y(mol SO/mol total) versus R (analyzer reading), which passes through the following points: y (log scale) R (rectangular scale) 0.00166 0.1107 20 90 The following data are taken: T = 75F P = 150 psig h(orifice meter) 210 mm R(SO2 analyzer) 82.4 (feed gas) R(SO2 analyzer) 11.6 (outlet gas) 4.1. Draw and label the whole process, including molar flow rates and molar fractions of all the gases streams 4.2. Calculate the mass fraction of sulphur dioxide in the liquid effluent stream 4.3. Determine the rate at which sulphur dioxide is removed from the feed gas (kg SO2/min).

Step by Step Solution

There are 3 Steps involved in it

Step: 1

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started