Answered step by step

Verified Expert Solution

Question

1 Approved Answer

1. Which type of production processing-job shop, batch, repetitive, or continuous-is the primary mode of operation at Stickley Furniture? Why? What other type of

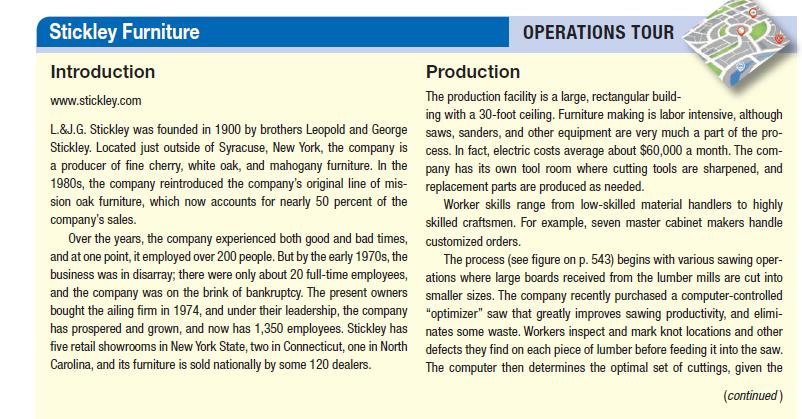

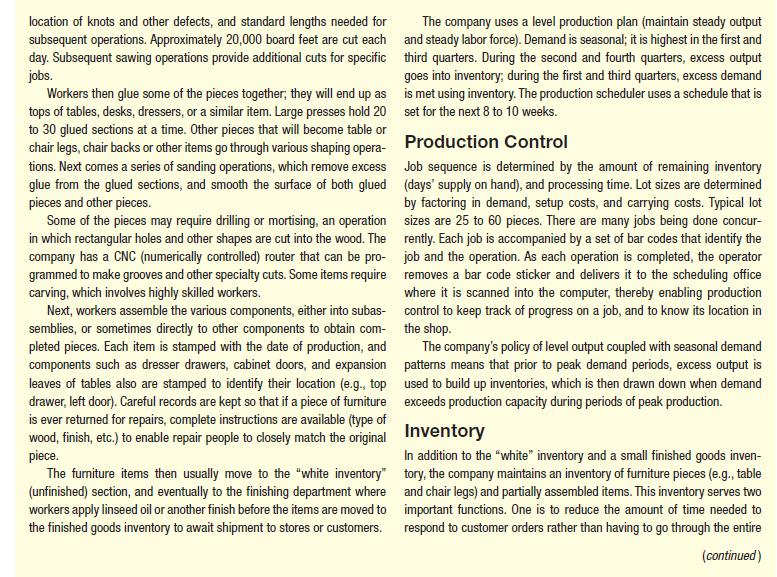

1. Which type of production processing-job shop, batch, repetitive, or continuous-is the primary mode of operation at Stickley Furniture? Why? What other type of processing is used to a lesser extent? Explain. 2. How does management keep track of job status and location during production? 3. Suppose the company has just received an order for 40 mission oak dining room sets. Briefly list the kinds of information the company will need to plan, schedule, and process this job. 4. What benefits, and what problems, would you expect, given the company's level production policy? 5. Can you suggest any changes that might be beneficial to the com- pany? What are they? Stickley Furniture OPERATIONS TOUR Introduction Production The production facility is a large, rectangular build- ing with a 30-foot ceiling. Furniture making is labor intensive, although www.stickley.com L&J.G. Stickley was founded in 1900 by brothers Leopold and George saws, sanders, and other equipment are very much a part of the pro- Stickley. Located just outside of Syracuse, New York, the company is cess. In fact, electric costs average about $60,000 a month. The com- a producer of fine cherry, white oak, and mahogany furniture. In the pany has its own tool room where cutting tools are sharpened, and 1980s, the company reintroduced the company's original line of mis- replacement parts are produced as needed. sion oak furniture, which now accounts for nearly 50 percent of the company's sales. Over the years, the company experienced both good and bad times, customized orders. and at one point, it employed over 200 people. But by the early 1970s, the business was in disarray; there were only about 20 full-time employees, ations where large boards received from the lumber mills are cut into and the company was on the brink of bankruptcy. The present owners smaller sizes. The company recently purchased a computer-controlled bought the ailing fim in 1974, and under their leadership, the company "optimizer" saw that greatly improves sawing productivity, and elimi- has prospered and grown, and now has 1,350 employees. Stickley has nates some waste. Workers inspect and mark knot locations and other five retail showrooms in New York State, two in Connecticut, one in North defects they find on each piece of lumber before feeding it into the saw. Carolina, and its furniture is sold nationally by some 120 dealers. Worker skills range from low-skilled material handlers to highly skilled craftsmen. For example, seven master cabinet makers handle The process (see figure on p. 543) begins with various sawing oper- The computer then determines the optimal set of cuttings, given the (continued) location of knots and other defects, and standard lengths needed for subsequent operations. Approximately 20,000 board feet are cut each and steady labor force). Demand is seasonal; it is highest in the first and day. Subsequent sawing operations provide additional cuts for specific third quarters. During the second and fourth quarters, excess output jobs. Workers then glue some of the pieces together, they will end up as is met using inventory. The production scheduler uses a schedule that is tops of tables, desks, dressers, or a similar item. Large presses hold 20 set for the next 8 to 10 weeks. to 30 glued sections at a time. Other pieces that will become table or chair legs, chair backs or other items go through various shaping opera- tions. Next comes a series of sanding operations, which remove excess Job sequence is determined by the amount of remaining inventory glue from the glued sections, and smooth the surface of both glued (days' supply on hand), and processing time. Lot sizes are determined pieces and other pieces. Some of the pieces may require drilling or mortising, an operation sizes are 25 to 60 pieces. There are many jobs being done concur- in which rectangular holes and other shapes are cut into the wood. The rently. Each job is accompanied by a set of bar codes that identify the company has a CNC (numerically controlled) router that can be pro- job and the operation. As each operation is completed, the operator grammed to make grooves and other specialty cuts. Some items require removes a bar code sticker and delivers it to the scheduling office carving, which involves highly skilled workers. Next, workers assemble the various components, either into subas- control to keep track of progress on a job, and to know its location in semblies, or sometimes directly to other components to obtain com- the shop. pleted pieces. Each item is stamped with the date of production, and components such as dresser drawers, cabinet doors, and expansion patterns means that prior to peak demand periods, excess output is leaves of tables also are stamped to identify their location (e.g., top used to build up inventories, which is then drawn down when demand drawer, left door). Careful records are kept so that if a piece of furniture exceeds production capacity during periods of peak production. is ever returned for repairs, complete instructions are available (type of The company uses a level production plan (maintain steady output goes into inventory; during the first and third quarters, excess demand Production Control by factoring in demand, setup costs, and carrying costs. Typical lot where it is scanned into the computer, thereby enabling production The company's policy of level output coupled with seasonal demand wood, finish, etc.) to enable repair people to closely match the original Inventory piece. The furniture items then usually move to the "white inventory" tory, the company maintains an inventory of furniture pieces (e.g., table (unfinished) section, and eventually to the finishing department where and chair legs) and partially assembled items. This inventory serves two workers apply linseed oil or another finish before the items are moved to important functions. One is to reduce the amount of time needed to the finished goods inventory to await shipment to stores or customers. In addition to the "white" inventory and a small finished goods inven- respond to customer orders rather than having to go through the entire (continued) production process to obtain needed items, and the other is that it helps to smooth production and utilize idle machinery/workers. Because of because pieces are being made for inventory, there is flexibility in unequal job times on successive operations, some workstations invari- sequencing. This permits jobs that have similar setups to be produced ably have slack time while others work at capacity. This is used to build in sequence, thereby reducing setup time and cost. an inventory of commonly used pieces and subassemblies. Moreover, (continued) Quality Each worker is responsible for checking his or her quality, as well as the quality of materials received from preceding operations, and to report any deficiencies. In addition, on several difficult operations, quality con- trol people handle inspections and work with operators to correct any deficiencies. The company is considering a TOM approach, but has not yet made a decision on whether to go in that direction.

Step by Step Solution

★★★★★

3.43 Rating (159 Votes )

There are 3 Steps involved in it

Step: 1

Gustav stickly formed Stickley brothers company in 1883 but later the company was dissolved and Stickley started working with Elgin Simmonds to form the firm of Stickley Simmonds in Binghamton New Yor...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started