I asked chegg expert last time but got this much wrong. Please help me. Thanks :).....

I asked chegg expert last time but got this much wrong. Please help me. Thanks :).....

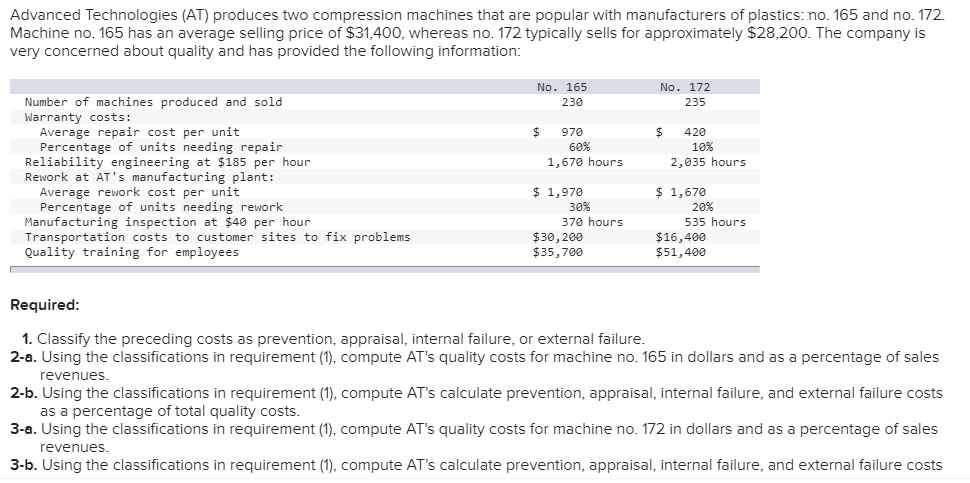

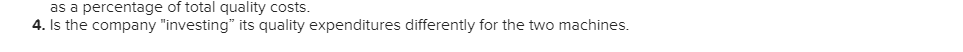

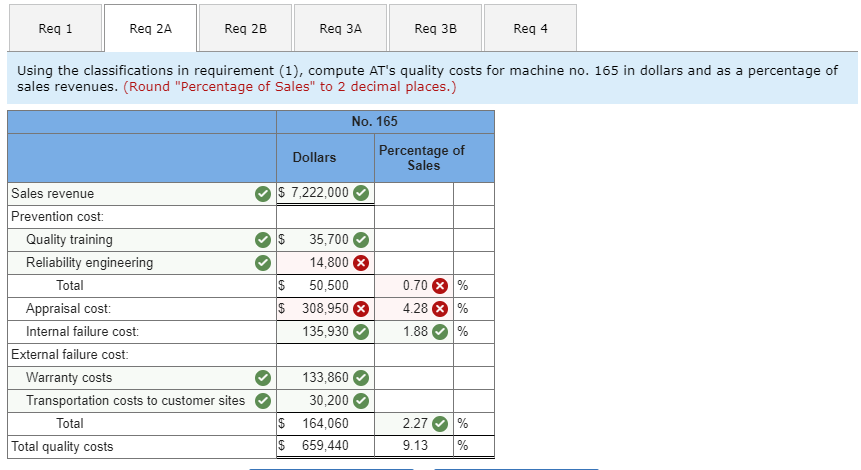

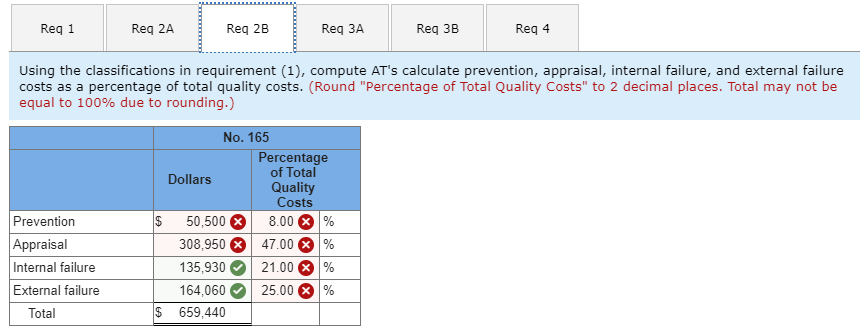

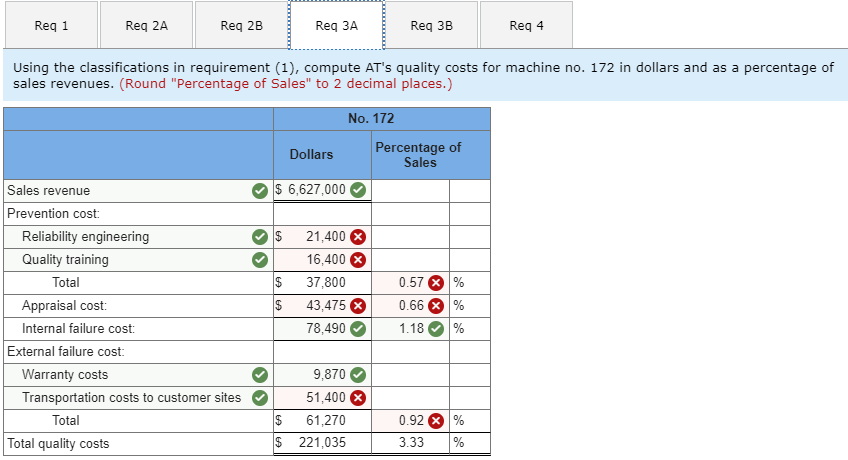

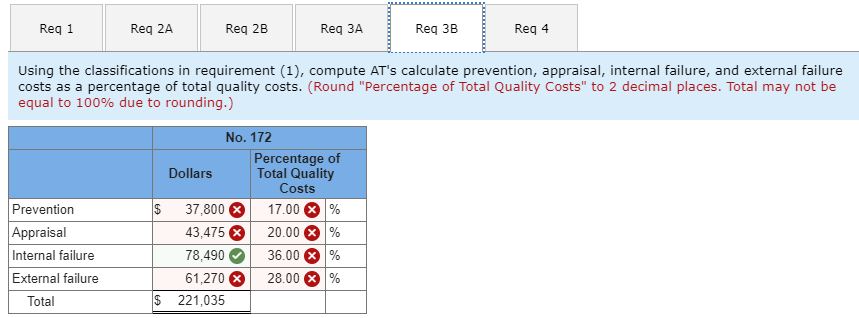

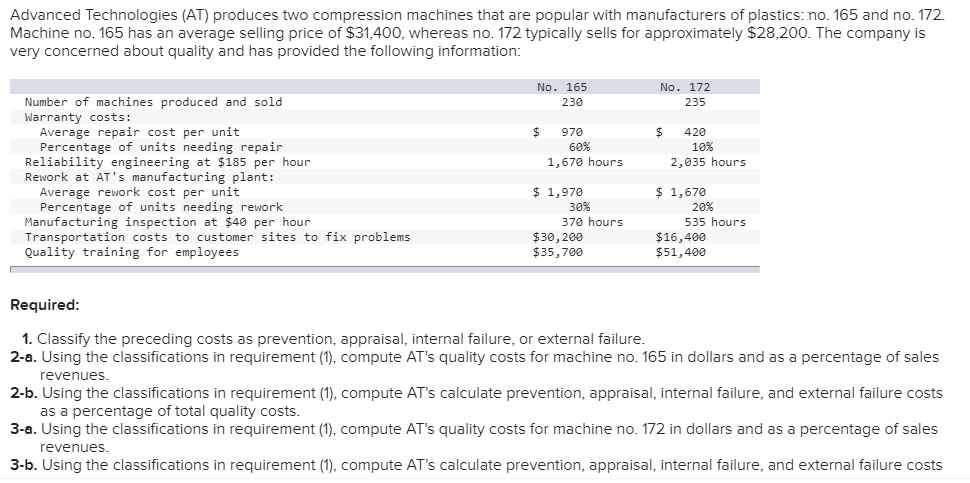

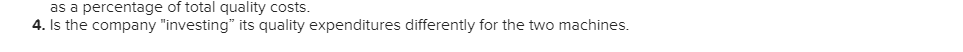

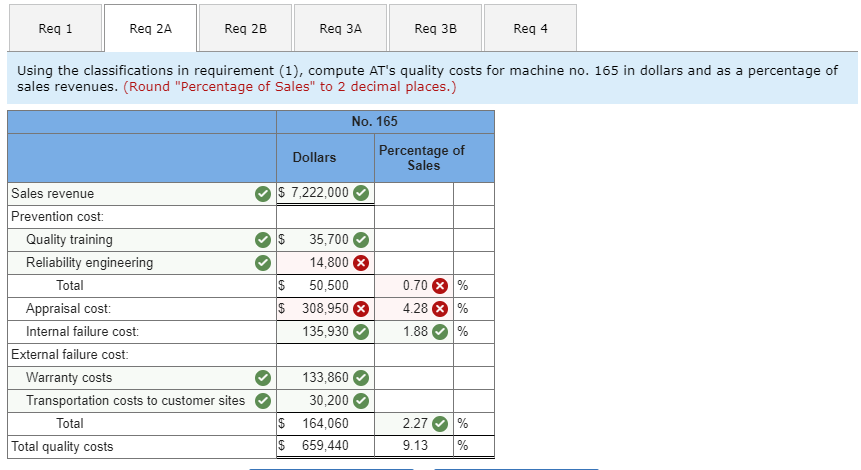

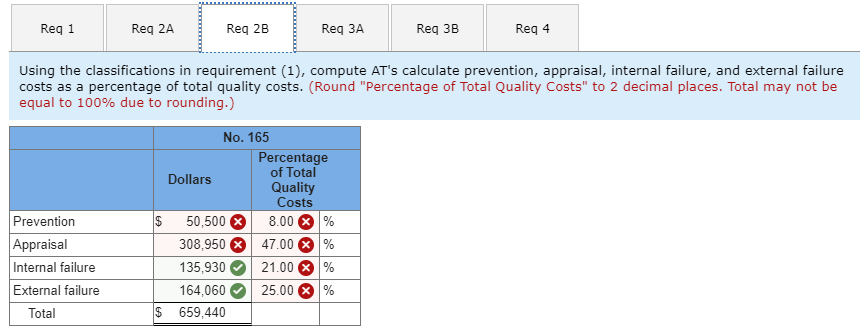

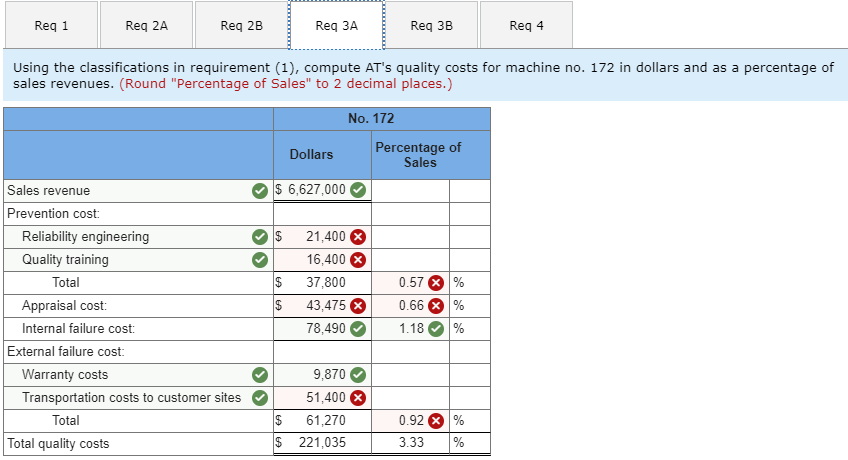

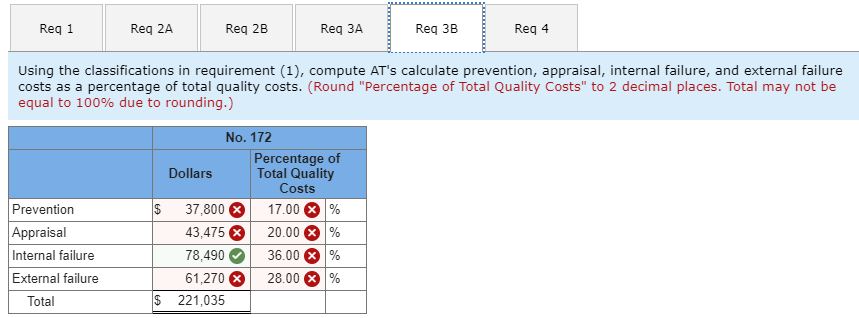

Advanced Technologies (AT) produces two compression machines that are popular with manufacturers of plastics: no. 165 and no. 172. Machine no. 165 has an average selling price of $31,400, whereas no. 172 typically sells for approximately $28,200. The company is very concerned about quality and has provided the following information: No. 165 No. 172 235 Number of machines produced and sold Warranty costs: Average repair cost per unit Percentage of units needing repair $ 970 $ 420 60% 10% Reliability engineering at $185 per hour Rework at AT's manufacturing plant: 1,670 hours 2,035 hours Average rework cost per unit $ 1,970 $ 1,670 Percentage of units needing rework Manufacturing inspection at $40 per hour Transportation costs to customer sites to fix problems Quality training for employees 30% 370 hours 20% 535 hours $30,200 $35,700 $16,400 $51,400 Required: 1. Classify the preceding costs as prevention, appraisal, internal failure, or external failure 2-a. Using the classifications in requirement (1), compute AT's quality costs for machine no. 165 in dollars and as a percentage of sales 2-b. Using the classifications in requirement (1), compute AT's calculate prevention, appraisal, internal failure, and external failure costs 3-a. Using the classifications in requirement (1), compute ATs quality costs for machine no. 172 in dollars and as a percentage of sales 3-b. Using the classifications in requirement (1), compute AT's calculate prevention, appraisal, internal failure, and external failure costs revenues as a percentage of total quality costs revenues as a percentage of total quality costs. 4. Is the company "investing" its quality expenditures differently for the two machines Req 1 Req 2A Req 2B Req 3A Req 3B Req 4 Using the classifications in requirement (1), compute AT's quality costs for machine no. 165 in dollars and as a percentage of sales revenues. (Round "Percentage of Sales" to 2 decimal places.) No. 165 Percentage of Sales Dollars Sales revenue 7,222.000 Prevention cost $ 35,700 14,800 S 50,500 $ 308,950 135,930 Quality training Reliability engineering Total Appraisal cost: Internal failure cost 4.28 X% External failure cost Warranty costs Transportation costs to customer sites 133,860 30,200 O Total $ 164,060 $ 659,440 Total quality costs 9.13 % Req 1 Req 2A Req 2B Req 3A Req 3B Req 4 Using the classifications in requirement (1), compute AT's calculate prevention, appraisal, internal failure, and external failure costs as a percentage of total quality costs. (Round "Percentage of Total Quality Costs" to 2 decimal places. Total may not be equal to 100% due to rounding.) No. 165 Percentage of Total Quality Costs Dollars Prevention Appraisal Internal failure External failure S 50,500 308,950 135,930 164,060 $ 659,440 47.00 x% 21.00% 25.00 X % Total Req 1 Req 2A Req 2B Req 3A Req 3B Req 4 Using the classifications in requirement (1), compute AT's quality costs for machine no. 172 in dollars and as a percentage of sales revenues. (Round "Percentage of Sales" to 2 decimal places.) No. 172 Percentage of Sales Dollars Sales revenue $ 6,627,000 Prevention cost Reliability engineering Quality training $ 21,400 16,400 $ 37,800 $ 43,475 78,490 Total Appraisal cost: Internal failure cost 0.66 X% 1.18 % External failure cost Warranty costs Transportation costs to customer sites 9,870 51,400 S 61,270 $ 221,035 Total 0.92 X% 3.33 % Total quality costs Req 1 Req 2A Req 2B Req 3A Req 3B Req 4 Using the classifications in requirement (1), compute AT's calculate prevention, appraisal, internal failure, and external failure costs as a percentage of total quality costs. (Round "Percentage of Total Quality Costs" to 2 decimal places. Total may not be equal to 100% due to rounding.) No. 172 Percentage of Total Quality Dollars Costs Prevention Appraisal Internal failure External failure $ 37,800 43,475 78,490 61,270 $ 221,035 17.00 x% 20.00 x% 36.0 % 28.00 % Total

I asked chegg expert last time but got this much wrong. Please help me. Thanks :).....

I asked chegg expert last time but got this much wrong. Please help me. Thanks :).....