Question

In this study, yarn warehouse layout, yarn transport between factories and stacking of yarns in the warehouse will be examined. In the figure, the yarns

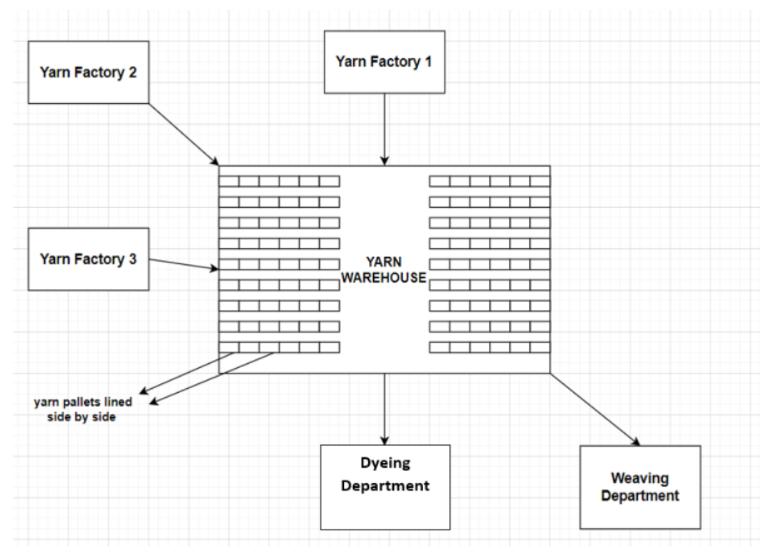

In this study, yarn warehouse layout, yarn transport between factories and stacking of yarns in the warehouse will be examined. In the figure, the yarns produced in the factories numbered 1, 2 and 3 are sent to the Yarn Warehouse. The yarns taken to the warehouse are sent to the relevant departments in line with the yarn needs of Dyeing and Weaving Departments. Depending on the production status in the Weaving and Dyeing Departments, the yarns are sometimes sent directly to the Dyeing and Weaving factories from the 1, 2 and 3 numbered factories without sending to warehouse. The yarns produced in the yarn factories are wrapped in bobbins and placed into the pallet. Each pallet has an average of 160 bobbins. Then, these pallets are sent to the warehouse or Dyeing and Weaving Department via trucks and forklifts. Factories wants to make improvements at some points in this cycle and a few of the desired improvements are as follows.

1- Yarn transfers between factories are made over SAP transactions. A label is created for each pallet and the informations on this label are entered to SAP manually. Transport operations are complated in this way. There may be erroneous data entries in these manual operations. In addition, these processes made through SAP are seen as a waste of time.

2- The pallets stacked in the Yarn Warehouse are shown in the figure. Traceability of pallets is carried out by addressing via SAP. For example, it is known that pallet A is in the 3rd place. If the required yarn stays close to the wall (in the back rows), All pallets in front are lifted one by one with the forklift and they are left in a suitable space. After the desired pallet is received, the other pallets are stacked in a random way again. For example, due to the lack of space in the weaving department, only a few palets yarn can be requested per shift for the next shift. The preparation of 1-shift yarns demanded by the weaving can take an average of 1.5 hours and therefore production losses occur.

3- Fabric production occurs with the combination of warp and weft yarns in the weaving department. While warp assignment can be made to a machine, this situation is not valid for weft yarns. Therefore, while tracking the amount of warp is done over the system, the amount of weft yarn cannot be followed up. For example, when x kg of weft yarn is sent to the Weaving Department, it is transferred via SAP as mentioned in item 1. With the transfer, the yarns appear to have been sent to the weaving department, but it cannot be tracked in detail through the system until x kg of weft is completely consumed. This is followed up by an operator by visiting around 300 machines one by one in the weaving department and counting the bobbins every day. Since this process does not give the correct results, It brings some problems such as inability to obtain the needs correctly and overproduction. Also, this counting takes about 2 hours of the operator.

1) Considering these problems, offer a new design and schematize the new process that will help some important problems such as minimizing the area occupied by the pallets in the yarn warehouse, yarn preparation times will be minimized and production losses will be reduced, forklift maintenance costs in the yarn warehouse will be saved, and energy costs due to unnecessary maneuvers of the forklift will be reduced, transport processes will be tracked with sensors and counting processes will be reduced or eliminated.

2) What kind of digital solutions can be integrated to the system for increasing the efficiency?

3) How does your solution affect the sustainability of the system?

Yarn Factory 2 Yarn Factory 3 yarn pallets lined side by side Yarn Factory 1 YARN WAREHOUSE Dyeing Department Weaving Department

Step by Step Solution

3.56 Rating (167 Votes )

There are 3 Steps involved in it

Step: 1

STEP 1 The proposed design for the yarn warehouse layout yarn transport between factories and stacking of yarn s in the warehouse will help to reduce ...

Get Instant Access to Expert-Tailored Solutions

See step-by-step solutions with expert insights and AI powered tools for academic success

Step: 2

Step: 3

Ace Your Homework with AI

Get the answers you need in no time with our AI-driven, step-by-step assistance

Get Started