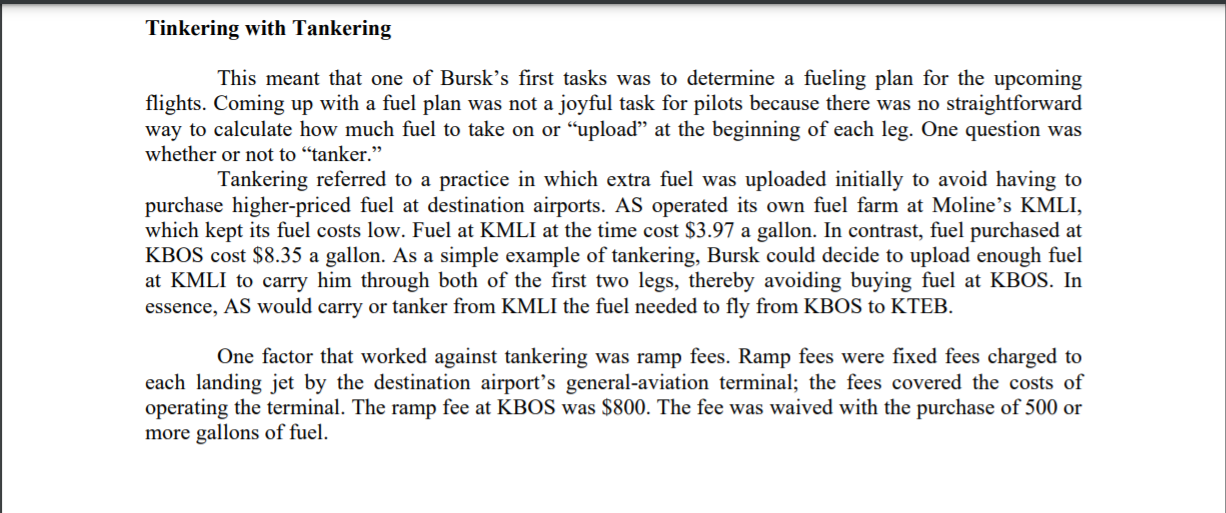

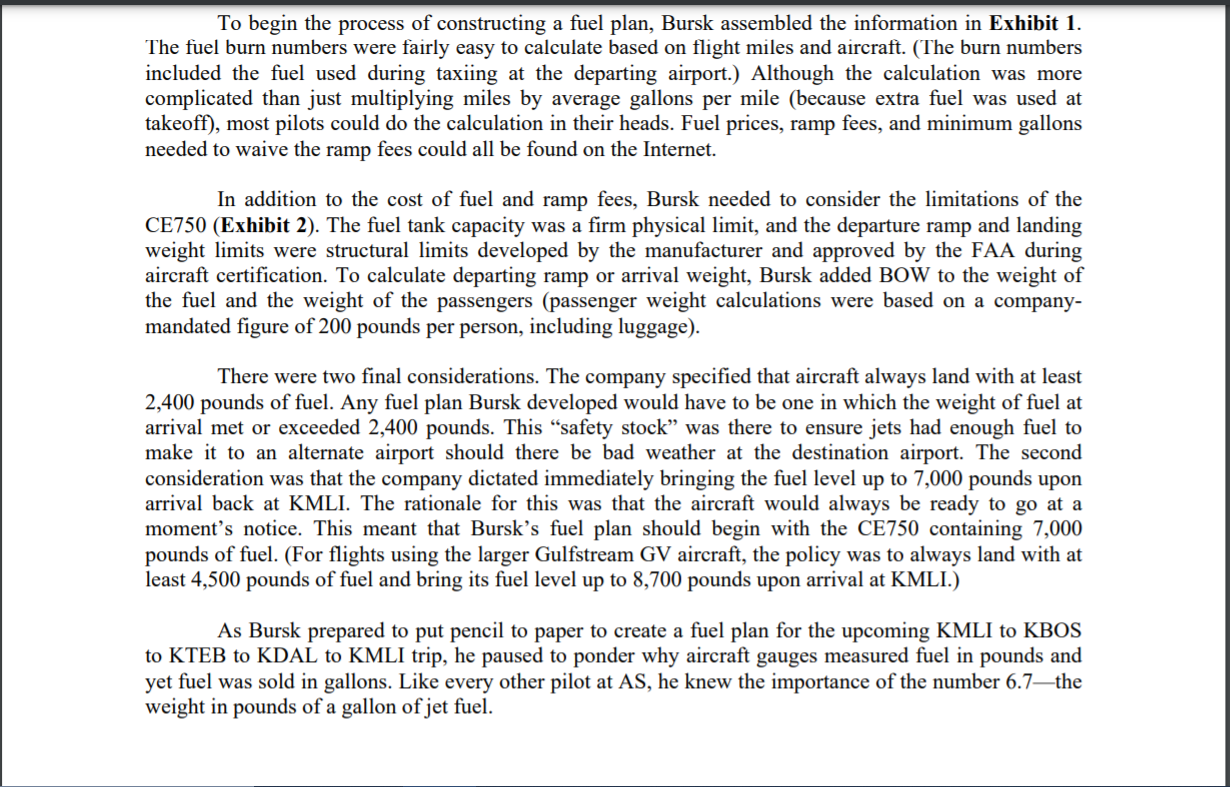

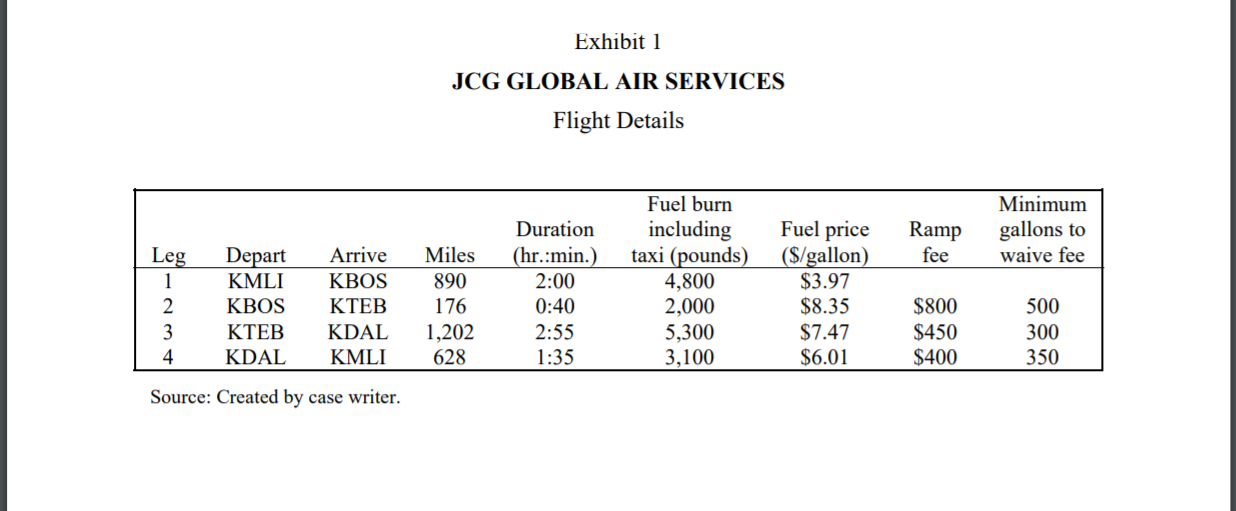

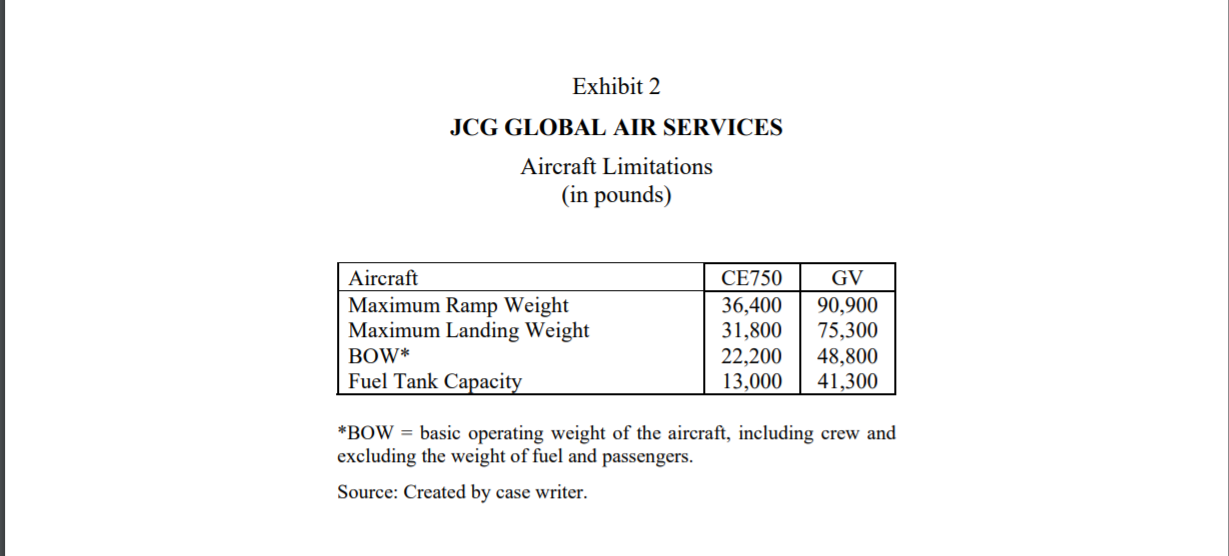

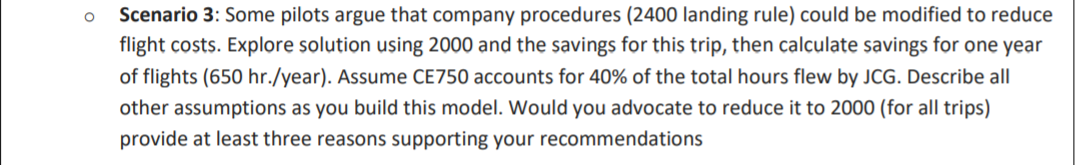

J CG GLOBAL AIR SERVICES Sam Bursk set about the task of preparing a fuel plan for his upcoming fourleg ight to Boston, Massachusetts; the New York City area; Dallas, Texas; and back. Like the other 13 corporate pilots he worked with, Bursk enjoyed ying a lot more than doing paperwork. But unlike some of his colleagues, Bursk rather enjoyed the challenge of constructing a fuel plan. J CG Global Air Services JCG Global Air Services (AS) operated four aircraft to serve the transportation needs of the corporate headquarters of the JCG Company. Located on a 1,415acrc campus in Molina, Illinois, the headquarters housed the executive and administrative staff of JCG's divisions along with a wide array of company-wide functions. Close to 2,400 JCG employees worked at headquarters. Company executives routinely used AS to fly to company factories, marketing facilities, and customer locations throughout the world. The company's largest and most expensive aircraft, the Gulfstream GV, had a range of 6,000 nautical miles. Purchased in 2001, it was flown throughout the world, including the growth areas of India and China. It could carry up to [3 passengers, a flight attendant. and two or three pilots. It burned fuel at a rate of approximately 450 gallons per hour. The rm owned and operated two Cessna Citation X aircraft (CE750), which it had purchased in 2002 and 2004. The CE750 (Figure l) was the fastest nonmilitary plane in the world and often went from Moline to as far as South America, Europe, and western Russia a larger range than most small jets. Its fuel burn rate of 310 gallons per hour coupled with its 13,000- pound-capacity tank meant that it required a fuel stop to reach these more distant destinations. It carried up to eight passengers and two pilots. The company's newest aircraft was a 2006 Cessna Citation Sovereign (CEGSD). Used only within North America, this craft carried up to eight passengers and burned le] at approximately 270 gallons per hour. Each of the four aircraft was budgeted for 650 ight hours per year, and AS had an annual budget of $22 millionless than 0.1% of company sales. The department consisted of 14 pilots (including the department manager and two pilot managers), six maintenance technicians, and four support staff members who were responsible for scheduling and ofce support. The Upcoming Flight In two days, the CEO and CFO of the JCG Corporation had a trip scheduled from Moline to Boston, the New York City area, Dallas, and then back to Moline. The purpose of the trip was to pick up some key analysts and mutual fund managers in Boston and New York and show them the new JCG factory in Dallas and the new JCG distribution center in Moline. They would be picking up two passengers in Boston and four in New York. As usual. AS would use the airport in Teterboro. New Jersey. as their destination in the New York City area; it was the closest airport to Wall Street. Manhattan. and the Lincoln Tunnel. Each U.S. airport carried a four-letter identifier beginning with the letter K. The upcoming four-leg ight would go from KMLI to KBOS to KTEB to KDAL and back to KMLI. Pilots at AS were responsible for creating and ling their own ight plans with the US. Federal Aviation Administration (FAA). One element of the flight plan was the takeoff and landing weight of the aircraft. To calculate these, one started with the basic operating weight (BOW) of the craft and added the weight of the passengers and fuel. The BOW included the structure of the aircraft, a stocked galley, emergency equipment, and the crew. The only weight components that varied from ight to ight were passengers and fuel. The only component that varied from takeoff to landing on a given flight was fuel. (For the purposes of this case study, we ignore the possibility of executive skydiving.) Tinkering with Tankering This meant that one of Bursk's first tasks was to determine a fueling plan for the upcoming flights. Coming up with a fuel plan was not a joyful task for pilots because there was no straightforward way to calculate how much fuel to take on or "upload" at the beginning of each leg. One question was whether or not to "tanker." Tankering referred to a practice in which extra fuel was uploaded initially to avoid having to purchase higher-priced fuel at destination airports. AS operated its own fuel farm at Moline's KMLI, which kept its fuel costs low. Fuel at KMLI at the time cost $3.97 a gallon. In contrast, fuel purchased at KBOS cost $8.35 a gallon. As a simple example of tankering, Bursk could decide to upload enough fuel at KMLI to carry him through both of the first two legs, thereby avoiding buying fuel at KBOS. In essence, AS would carry or tanker from KMLI the fuel needed to fly from KBOS to KTEB. One factor that worked against tankering was ramp fees. Ramp fees were fixed fees charged to each landing jet by the destination airport's general-aviation terminal; the fees covered the costs of operating the terminal. The ramp fee at KBOS was $800. The fee was waived with the purchase of 500 or more gallons of fuel.To begin the process of constructing a re] plan, Bursk assembled the information in Exhibit 1. The fuel burn numbers were fairly easy to calculate based on flight miles and aircraft. (The burn numbers included the fuel used during taxiing at the departing airport.) Although the calculation was more complicated than just multiplying miles by average gallons per mile (because extra le] was used at takeoff), most pilots could do the calculation in their heads- Fuel prices, ramp fees, and minimum gallons needed to waive the ramp fees could all he found on the Internet. In addition to the cost of le] and ramp fees, Bursk needed to consider the limitations of the CE750 (Exhibit 2). The iel tank capacity was a rm physical limit, and the departure ramp and landing weight limits were structural limits developed by the manufacturer and approved by the FAA during aircraft certication. To calculate departing ramp or arrival weight, Bursk added BOW to the weight of the fuel and the weight of the passengers (passenger weight calculations were based on a company- mandated gure of 200 pounds per person, including luggage}. There were two final considerations- The company specied that aircraft always land with at least 2,400 pounds of fuel. Any fuel plan Bursk developed would have to be one in which the weight of rel at arrival met or exceeded 2,400 pounds. This \"safety stock\" was there to ensure jets bad enough fuel to make it to an alternate airport should there be bad weather at the destination airport. The second consideration was that the company dictated immediately bringing the fuel level up to 7,000 pounds upon arrival back at KMLI. The rationale for this was that the aircraft would always be ready to go at a moment's notice. This meant that Bursk's fuel plan should begin with the CE750 containing 7,000 pounds of fuel. (For ights using the larger Gulfstream GV aircra, the policy was to always land with at least 4,500 pounds of fuel and bring its fuel level up to 8,700 pounds upon arrival at KMLI.) As Bursk prepared to put pencil to paper to create a fuel plan for the upcoming KMLl to KBOS to KTEB to KDAL to XML] trip, he paused to ponder why aircraft gauges measured fuel in pounds and yet fuel was sold in gallons. Like every other pilot at AS, he knew the importance of the number 6.7the weight in pounds of a gallon of jet fuel. Exhibit ] JCG GLOBAL AIR SERVICES Flight Details Fuel burn Minimum including Fuel price gallons to waive fee Source: Created by case writer. Exhibit 2 J CG GLOBAL AIR SERVICES Aircraft Limitations (in pounds) Maximum Ramp Weight Maximum Landing Weight BOW" Fuel Tank Ca - aci *BOW = basic operating weight of the aircra. including crew and excluding the weight ofael and passengers. Source: Created by case writer. O Scenario 3: Some pilots argue that company procedures (2400 landing rule) could be modified to reduce flight costs. Explore solution using 2000 and the savings for this trip, then calculate savings for one year of flights (650 hr./year). Assume CE750 accounts for 40% of the total hours flew by JCG. Describe all other assumptions as you build this model. Would you advocate to reduce it to 2000 (for all trips) provide at least three reasons supporting your recommendations