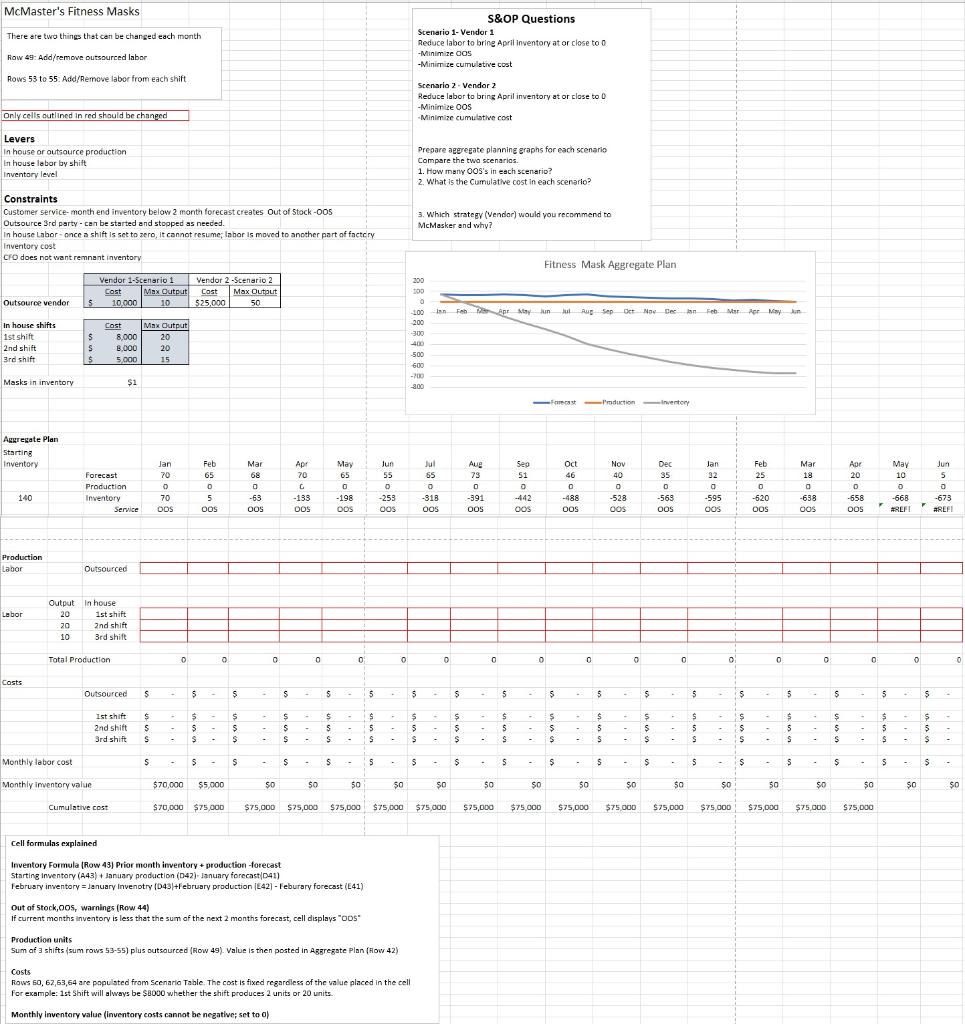

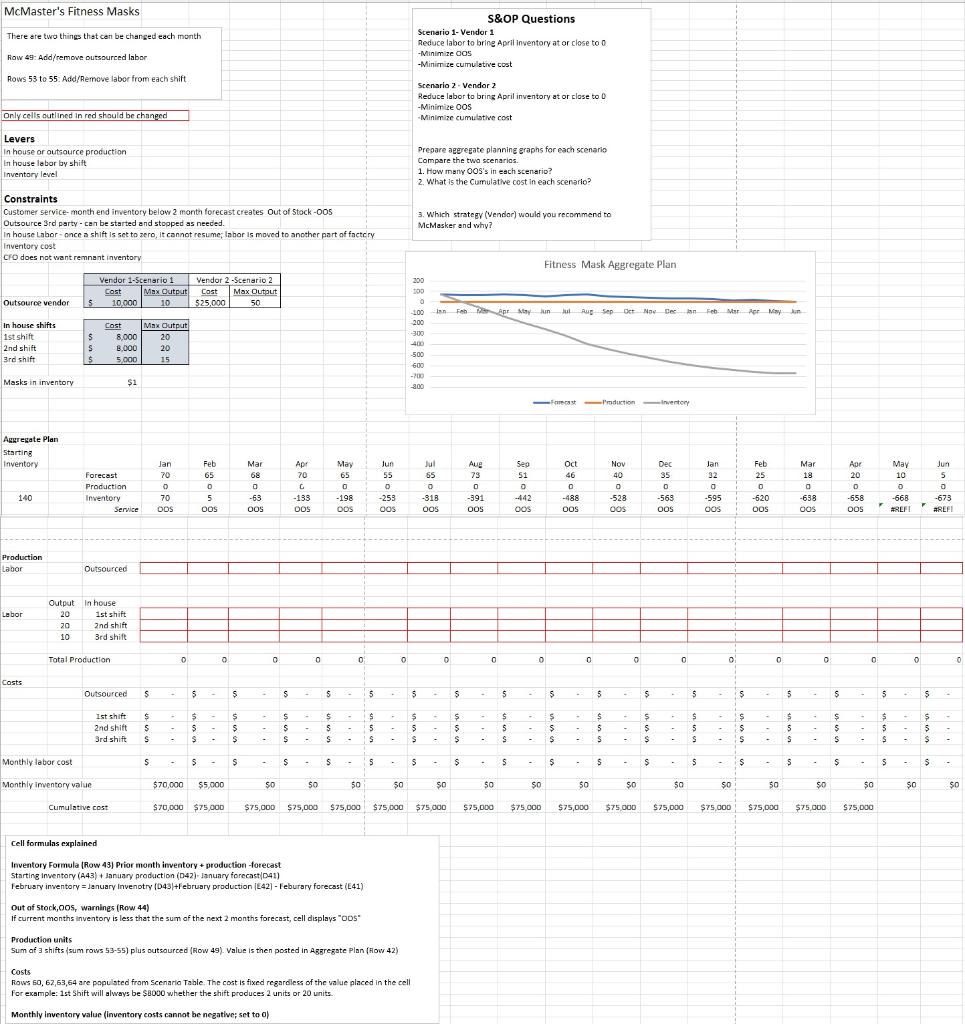

McMaster's Fitness Masks There are two things that can be changed each month S&OP Questions Scenario 1- Vendor 1 Reduce labor to bring April inventory at or close to - Minimize DOS -Minimize cumulative cost Row 49 Add/remove outsourced labor Rows 53 to 55. Add/Remove labor from each shift Scenario 2 - Vendor 2 Reduce labor to bring April inventory at or close to -Minimize OOS Minimize cumulative cost Only cells outlined in red should be changed Levers In house or outsource production In house labor by shift Inventory level Prepare aegregate planning graphs for each scenario Compare the two scenarios. 1. How many OOS's in each scenario? 2. What is the Cumulative cost in each scenario? Constraints Customer service-month end inventory below 2 month forecast creates Out of Stock-Oos Outsource 3rd party - can be started and stopped as needed. In house Labor-once a shift is set to zero, It cannot resume; laboris moved to another part of factory Inventory cost CFO does not want remnant inventory 3. Which strategy (Vendor) would you recommend to McMasker and why? Fitness Mask Aggregate Plan Vendor 1-Scenario 1 Vendor 2 -Scenario 2 Cost Max Output Cost Max Output 10.000 10 $25,000 50 Outsource vendor $ 200 100 0 -200 200 300 400 innebApr May Jun Jul Aug Sep Oct Noe Declan Feb Mar Apr May Jun Na In house shifts 1st shift 2nd shift 3rd shift S S $ Cast Max Output 8,000 20 8.000 20 5.000 15 -500 600 -200 -800 Masks in inventory $1 Production Inventory Aggregate Plan Starting Inventory May 65 Feb 25 Jun 5 Jan 70 o 70 OOS Forecast Production Inventory Service Feb 65 0 5 OOS Mar 68 0 -63 OOS Apr 70 C -133 OOS Jun 55 0 -253 OOS Jul 65 0 -318 OOS Aug 73 0 0 -391 OOS Seo 51 0 0 -442 00 Oct 46 0 -488 OOS 40 0 -528 OOS Dec 35 0 -563 OOS Jan 32 0 -595 OOS May 10 0 Mar 18 0 -638 OOS Aor 20 0 -658 OOS 140 -668 -198 OOS -520 OOS #REFI -67 AREFI Production Labor Outsourced Labor Output In house 20 1st shift 20 2nd shift 10 3rd shift Total Production 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Costs Outsourced $ $ $ S S $ . 5 s s 5 S $ S $ 5 $ 5 $ $ $ $ s Ist shift 2nd shift 3rd shift $ $ S $ $ $ $ - $ $ $ $ s $ $ - - - $ S s s $ - S - IS $ $ s - $ $ $ $ $ S s - - $ $ $ - - - - - $ S S - $ $ $ - - $ $ s - - $ $ S - - $ $ S $ $ $ $ $ $ $ 1 $ S $ $ $ - . - - Monthly labor cost S $ $ S S S $ $ S - $ - $ $ $ $ $ s $ $ $ Monthly inventory value $70,000 $5,000 SO $0 50 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 Cumulative cost $70,000 $75,000 $75,000 $75,000 $75,000 $75,000 $75,000 $75,000 $75,000 $75,000 $75 000 $75,000 $75,000 $75,000 $75,000 $75,000 Cell formulas explained Inventory Formula (Row 43) Prior month inventory + production -forecast Starting inventory (A43) + January production (042) January forecast 1041) February inventory = January Inventry (D43/+February production (E42) - Feburary forecast (141) Out of Stock,oos, warnings (Row 44) If current months inventory is less that the sum of the next 2 months forecast, cell displays "Oos" Production units Sum of 3 shifts (sum rows 53-55) plus outsourced (Row 49). Value is then posted in Aggregate Plan (Row 42) Costs Rows 60, 62, 63,64 are populated from Scenaria Table. The cost is fixed regardless of the value placed in the cell For example: 1st Shift will always be $8000 whether the shift produces 2 units or 20 units. Monthly Inventory value (Inventory costs cannot be negative; set too) McMaster's Fitness Masks There are two things that can be changed each month S&OP Questions Scenario 1- Vendor 1 Reduce labor to bring April inventory at or close to - Minimize DOS -Minimize cumulative cost Row 49 Add/remove outsourced labor Rows 53 to 55. Add/Remove labor from each shift Scenario 2 - Vendor 2 Reduce labor to bring April inventory at or close to -Minimize OOS Minimize cumulative cost Only cells outlined in red should be changed Levers In house or outsource production In house labor by shift Inventory level Prepare aegregate planning graphs for each scenario Compare the two scenarios. 1. How many OOS's in each scenario? 2. What is the Cumulative cost in each scenario? Constraints Customer service-month end inventory below 2 month forecast creates Out of Stock-Oos Outsource 3rd party - can be started and stopped as needed. In house Labor-once a shift is set to zero, It cannot resume; laboris moved to another part of factory Inventory cost CFO does not want remnant inventory 3. Which strategy (Vendor) would you recommend to McMasker and why? Fitness Mask Aggregate Plan Vendor 1-Scenario 1 Vendor 2 -Scenario 2 Cost Max Output Cost Max Output 10.000 10 $25,000 50 Outsource vendor $ 200 100 0 -200 200 300 400 innebApr May Jun Jul Aug Sep Oct Noe Declan Feb Mar Apr May Jun Na In house shifts 1st shift 2nd shift 3rd shift S S $ Cast Max Output 8,000 20 8.000 20 5.000 15 -500 600 -200 -800 Masks in inventory $1 Production Inventory Aggregate Plan Starting Inventory May 65 Feb 25 Jun 5 Jan 70 o 70 OOS Forecast Production Inventory Service Feb 65 0 5 OOS Mar 68 0 -63 OOS Apr 70 C -133 OOS Jun 55 0 -253 OOS Jul 65 0 -318 OOS Aug 73 0 0 -391 OOS Seo 51 0 0 -442 00 Oct 46 0 -488 OOS 40 0 -528 OOS Dec 35 0 -563 OOS Jan 32 0 -595 OOS May 10 0 Mar 18 0 -638 OOS Aor 20 0 -658 OOS 140 -668 -198 OOS -520 OOS #REFI -67 AREFI Production Labor Outsourced Labor Output In house 20 1st shift 20 2nd shift 10 3rd shift Total Production 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 0 Costs Outsourced $ $ $ S S $ . 5 s s 5 S $ S $ 5 $ 5 $ $ $ $ s Ist shift 2nd shift 3rd shift $ $ S $ $ $ $ - $ $ $ $ s $ $ - - - $ S s s $ - S - IS $ $ s - $ $ $ $ $ S s - - $ $ $ - - - - - $ S S - $ $ $ - - $ $ s - - $ $ S - - $ $ S $ $ $ $ $ $ $ 1 $ S $ $ $ - . - - Monthly labor cost S $ $ S S S $ $ S - $ - $ $ $ $ $ s $ $ $ Monthly inventory value $70,000 $5,000 SO $0 50 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 $0 Cumulative cost $70,000 $75,000 $75,000 $75,000 $75,000 $75,000 $75,000 $75,000 $75,000 $75,000 $75 000 $75,000 $75,000 $75,000 $75,000 $75,000 Cell formulas explained Inventory Formula (Row 43) Prior month inventory + production -forecast Starting inventory (A43) + January production (042) January forecast 1041) February inventory = January Inventry (D43/+February production (E42) - Feburary forecast (141) Out of Stock,oos, warnings (Row 44) If current months inventory is less that the sum of the next 2 months forecast, cell displays "Oos" Production units Sum of 3 shifts (sum rows 53-55) plus outsourced (Row 49). Value is then posted in Aggregate Plan (Row 42) Costs Rows 60, 62, 63,64 are populated from Scenaria Table. The cost is fixed regardless of the value placed in the cell For example: 1st Shift will always be $8000 whether the shift produces 2 units or 20 units. Monthly Inventory value (Inventory costs cannot be negative; set too)