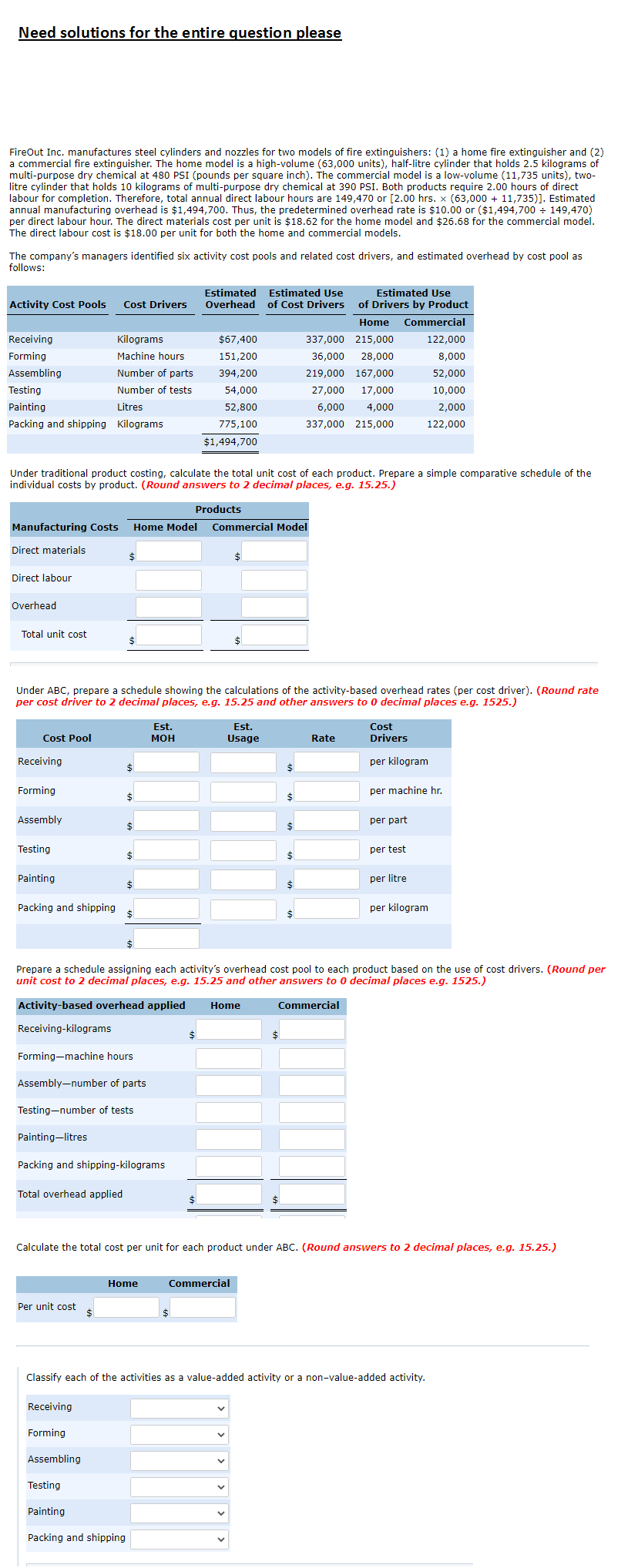

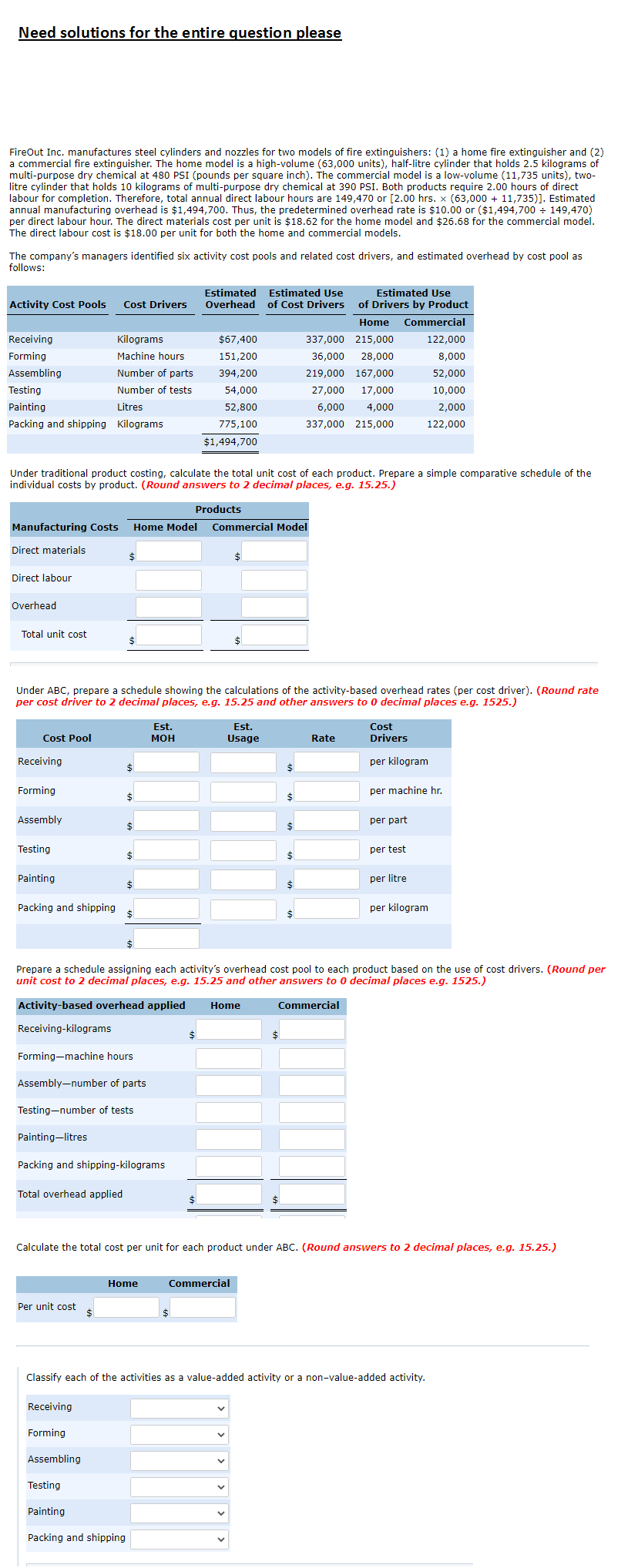

Need solutions for the entire question please FireOut Inc. manufactures steel cylinders and nozzles for two models of fire extinguishers: (1) a home fire extinguisher and (2) a commercial fire extinguisher. The home model is a high-volume (63,000 units), half-litre cylinder that holds 2.5 kilograms of multi-purpose dry chemical at 480 PSI (pounds per square inch). The commercial model is a low-volume (11,735 units), two- litre cylinder that holds 10 kilograms of multi-purpose dry chemical at 390 PSI. Both products require 2.00 hours of direct labour for completion. Therefore, total annual direct labour hours are 149,470 or [2.00 hrs. * (63,000 + 11,735)]. Estimated annual manufacturing overhead is $1,494,700. Thus, the predetermined overhead rate is $10.00 or ($1,494,700 - 149,470) per direct labour hour. The direct materials cost per unit is $18.62 for the home model and $26.68 for the commercial model. The direct labour cost is $18.00 per unit for both the home and commercial models. The company's managers identified six activity cost pools and related cost drivers, and estimated overhead by cost pool as follows: Activity Cost Pools Cost Drivers Receiving Kilograms Forn Machine hours Assembling Number of parts Testing Number of tests Painting Litres Packing and shipping Kilograms Estimated Estimated Use Estimated Use Overhead of Cost Drivers of Drivers by Product Home Commercial $67,400 337,000 215,000 122,000 36,000 28,000 8,000 394,200 219,000 167,000 52,000 54,000 27,000 17,000 10,000 52,800 6,000 4,000 2,000 775,100 337,000 215,000 122,000 $1,494,700 Under traditional product costing, calculate the total unit cost of each product. Prepare a simple comparative schedule of the individual costs by product. (Round answers to 2 decimal places, e.g. 15.25.) Products Home Model Commercial Model Manufacturing Costs Direct materials $ Direct labour Overhead Total unit cost Under ABC, prepare a schedule showing the calculations of the activity-based overhead rates (per cost driver). (Round rate per cost driver to 2 decimal places, e.g. 15.25 and other answers to 0 decimal places e.g. 1525.) Est. MOH Cost Pool Est. Usage Rate Cost Drivers Receiving per kilogram $ Forming per machine hr. $ $ Assembly per part Testing per test $ $ Painting per litre $ $ Packing and shipping per kilogram $ Prepare a schedule assigning each activity's overhead cost pool to each product based on the use of cost drivers. (Round per unit cost to 2 decimal places, e.g. 15.25 and other answers to o decimal places e.g. 1525.) Activity-based overhead applied Home Commercial Receiving-kilograms Forming-machine hours Assembly-number of parts Testing-number of tests Painting-litres Packing and shipping-kilograms Total overhead applied Calculate the total cost per unit for each product under ABC. (Round answers to 2 decimal places, e.g. 15.25.) Home Commercial Per unit cost Classify each of the activities as a value-added activity or a non-value-added activity. Receiving Forming Assembling Testing Painting Packing and shipping