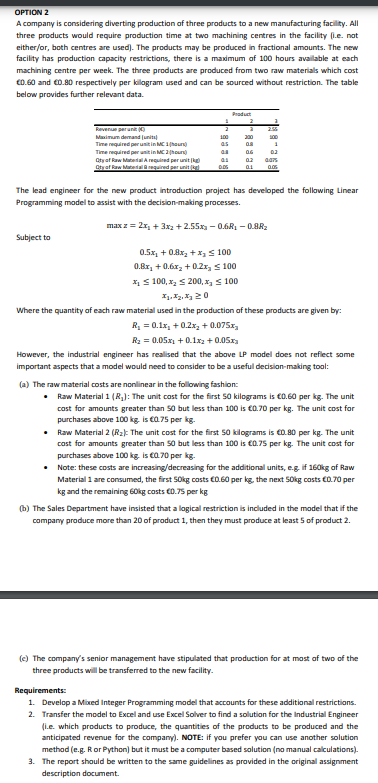

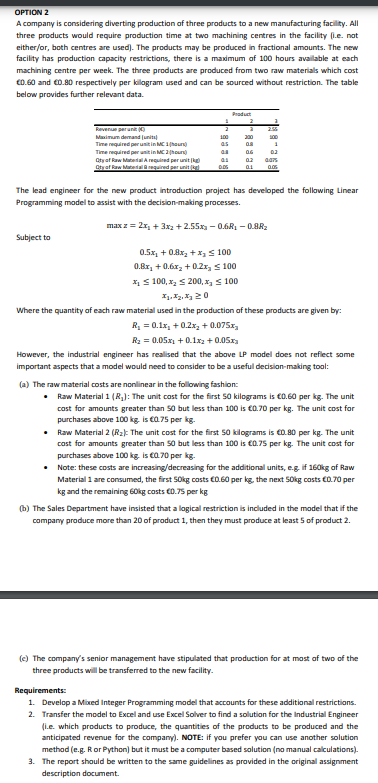

OPTION 2 A company is considering diverting production of three products to a new manufacturing facility. All three products would require production time at two machining centres in the facility i.e. not either/or, both centres are used). The products may be produced in fractional amounts. The new facility has production capacity restrictions, there is a maximum of 100 hours available at each machining centre per week. The three products are produced from two raw materials which cost 60.60 and 60.80 respectively per kilogram used and can be sourced without restriction. The table below provides further relevant data. Prada 2 2.55 2 100 200 08 1 Revenue part 10 Maximum demand unit Time required perustico Time required per incon Qty of water per te Qty Regine per unit 03 0.3 01 00 The lead engineer for the new product introduction project has developed the following Linear Programming model to assist with the decision-making processes. maxz= 2x + 3x3 +2.55x3 -0.6R: -0.8 R2 Subject to 0.5x + 0.8x2 + x, S 100 0.Bx, +0.6x2 +0.2x, S 100 x 100,X2 200,X, S 100 X, X, X, 20 Where the quantity of each raw material used in the production of these products are given by: R, = 0.1x, +0.2x2 +0.075x R2 = 0.05x2 +0.1x2 +0.05.x, However, the industrial engineer has realised that the above LP model does not reflect some important aspects that a model would need to consider to be a useful decision-making tool: (a) The raw material costs are nonlinear in the following fashion Raw Material 1 (R.): The unit cost for the first 50 kilograms is 0.60 per kg. The unit cost for amounts greater than 50 but less than 100 is 0.70 per kg. The unit cost for purchases above 100 kg, is 0.75 per kg. Raw Material 2 (R2): The unit cost for the first 50 kilograms is 0.80 per kg. The unit cost for amounts greater than 50 but less than 100 is 0.75 per kg. The unit cost for purchases above 100 kg, is 70 per kg. Note: these costs are increasing/decreasing for the additional units, e.gif 160kg of Raw Material 1 are consumed, the first Sokg costs 0.60 per kg. the next Sokg costs 0.70 per kg and the remaining 60kg costs 0.75 per kg (b) The Sales Department have insisted that a logical restriction is included in the model that if the company produce more than 20 of product 1, then they must produce at least 5 of product 2. le) The company's senior management have stipulated that production for at most of two of the three products will be transferred to the new facility Requirements: 1. Develop a Mixed Integer Programming model that accounts for these additional restrictions. 2. Transfer the model to Excel and use Excel Solver to find a solution for the Industrial Engineer fi.e. which products to produce, the quantities of the products to be produced and the anticipated revenue for the company). NOTE: If you prefer you can use another solution method(e.g. R or Python) but it must be a computer based solution (no manual calculations). 3. The report should be written to the same guidelines as provided in the original assignment description document. OPTION 2 A company is considering diverting production of three products to a new manufacturing facility. All three products would require production time at two machining centres in the facility i.e. not either/or, both centres are used). The products may be produced in fractional amounts. The new facility has production capacity restrictions, there is a maximum of 100 hours available at each machining centre per week. The three products are produced from two raw materials which cost 60.60 and 60.80 respectively per kilogram used and can be sourced without restriction. The table below provides further relevant data. Prada 2 2.55 2 100 200 08 1 Revenue part 10 Maximum demand unit Time required perustico Time required per incon Qty of water per te Qty Regine per unit 03 0.3 01 00 The lead engineer for the new product introduction project has developed the following Linear Programming model to assist with the decision-making processes. maxz= 2x + 3x3 +2.55x3 -0.6R: -0.8 R2 Subject to 0.5x + 0.8x2 + x, S 100 0.Bx, +0.6x2 +0.2x, S 100 x 100,X2 200,X, S 100 X, X, X, 20 Where the quantity of each raw material used in the production of these products are given by: R, = 0.1x, +0.2x2 +0.075x R2 = 0.05x2 +0.1x2 +0.05.x, However, the industrial engineer has realised that the above LP model does not reflect some important aspects that a model would need to consider to be a useful decision-making tool: (a) The raw material costs are nonlinear in the following fashion Raw Material 1 (R.): The unit cost for the first 50 kilograms is 0.60 per kg. The unit cost for amounts greater than 50 but less than 100 is 0.70 per kg. The unit cost for purchases above 100 kg, is 0.75 per kg. Raw Material 2 (R2): The unit cost for the first 50 kilograms is 0.80 per kg. The unit cost for amounts greater than 50 but less than 100 is 0.75 per kg. The unit cost for purchases above 100 kg, is 70 per kg. Note: these costs are increasing/decreasing for the additional units, e.gif 160kg of Raw Material 1 are consumed, the first Sokg costs 0.60 per kg. the next Sokg costs 0.70 per kg and the remaining 60kg costs 0.75 per kg (b) The Sales Department have insisted that a logical restriction is included in the model that if the company produce more than 20 of product 1, then they must produce at least 5 of product 2. le) The company's senior management have stipulated that production for at most of two of the three products will be transferred to the new facility Requirements: 1. Develop a Mixed Integer Programming model that accounts for these additional restrictions. 2. Transfer the model to Excel and use Excel Solver to find a solution for the Industrial Engineer fi.e. which products to produce, the quantities of the products to be produced and the anticipated revenue for the company). NOTE: If you prefer you can use another solution method(e.g. R or Python) but it must be a computer based solution (no manual calculations). 3. The report should be written to the same guidelines as provided in the original assignment description document