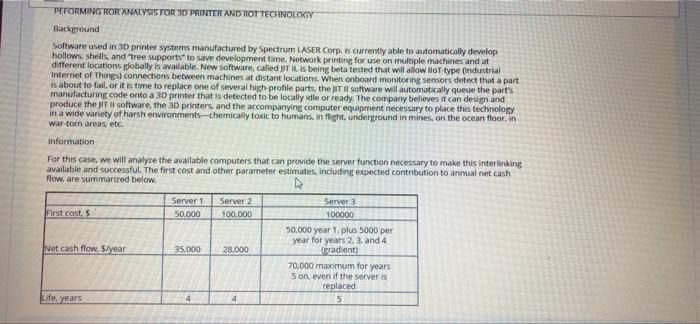

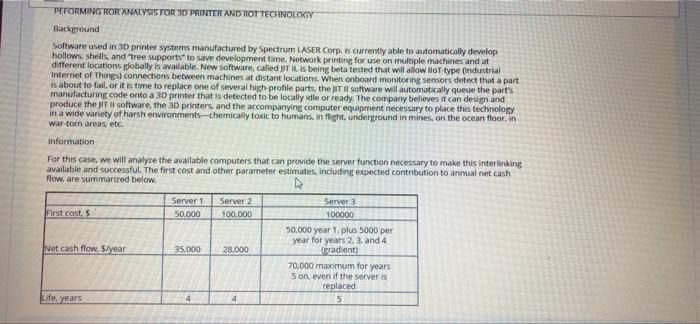

PEFORMING ROR ANALYSIS FOR 3D PRINTER AND TOT TECHNOLOGY Background Software used in 3D printer systems manufactured by Spectrum LASER Corp. is currently able to automatically develop hollows, shells, and tree supports to save development time. Network printing for use on multiple machines and at different locations globally is available. New software, called ITIL is being beta tested that will allow IoT-type industrial Internet of Things connections between machines at distant locations. When onboard monitoring sensors detect that a part is about to fail or it is time to replace one of several high-profile parts, the IT software will automatically quede the part's manufacturing code onto a 3D printer that is detected to be locally idle or ready. The company believes it can design and produce the IT software, the 3D printers, and the accompanying computer equipment necessary to place this technology in a wide variety of harsh environments---chemically toxic to humans. In fight, underground in mines, on the ocean floor, in war tom areas, etc Information For this case, we will analyze the available computers that can provide the server function necessary to make this interlinking available and successful. The first cost and other parameter estimates, including expected contribution to annual net cash flow, are summarized below Server 1 Server 2 Server First costs 50.000 100,000 100000 50.000 year 1. plus 5000 per year for years 2. 3. and 4 Net cash flow. S/year 35,000 28.000 gradient) 70,000 maximum for years 5 on, even if the serveris replaced Life years 5 PEFORMING ROR ANALYSIS FOR 3D PRINTER AND TOT TECHNOLOGY Background Software used in 3D printer systems manufactured by Spectrum LASER Corp. is currently able to automatically develop hollows, shells, and tree supports to save development time. Network printing for use on multiple machines and at different locations globally is available. New software, called ITIL is being beta tested that will allow IoT-type industrial Internet of Things connections between machines at distant locations. When onboard monitoring sensors detect that a part is about to fail or it is time to replace one of several high-profile parts, the IT software will automatically quede the part's manufacturing code onto a 3D printer that is detected to be locally idle or ready. The company believes it can design and produce the IT software, the 3D printers, and the accompanying computer equipment necessary to place this technology in a wide variety of harsh environments---chemically toxic to humans. In fight, underground in mines, on the ocean floor, in war tom areas, etc Information For this case, we will analyze the available computers that can provide the server function necessary to make this interlinking available and successful. The first cost and other parameter estimates, including expected contribution to annual net cash flow, are summarized below Server 1 Server 2 Server First costs 50.000 100,000 100000 50.000 year 1. plus 5000 per year for years 2. 3. and 4 Net cash flow. S/year 35,000 28.000 gradient) 70,000 maximum for years 5 on, even if the serveris replaced Life years 5