please fill in the chart

please fill in the chart

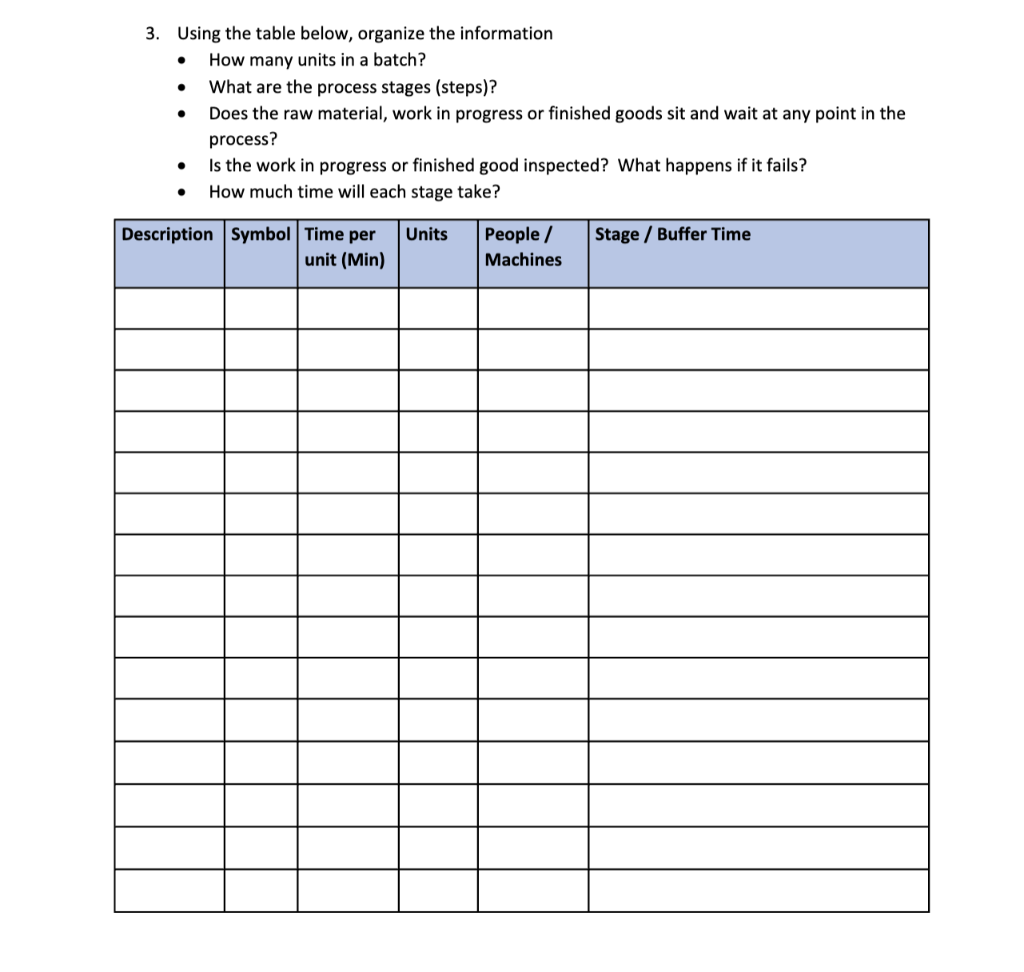

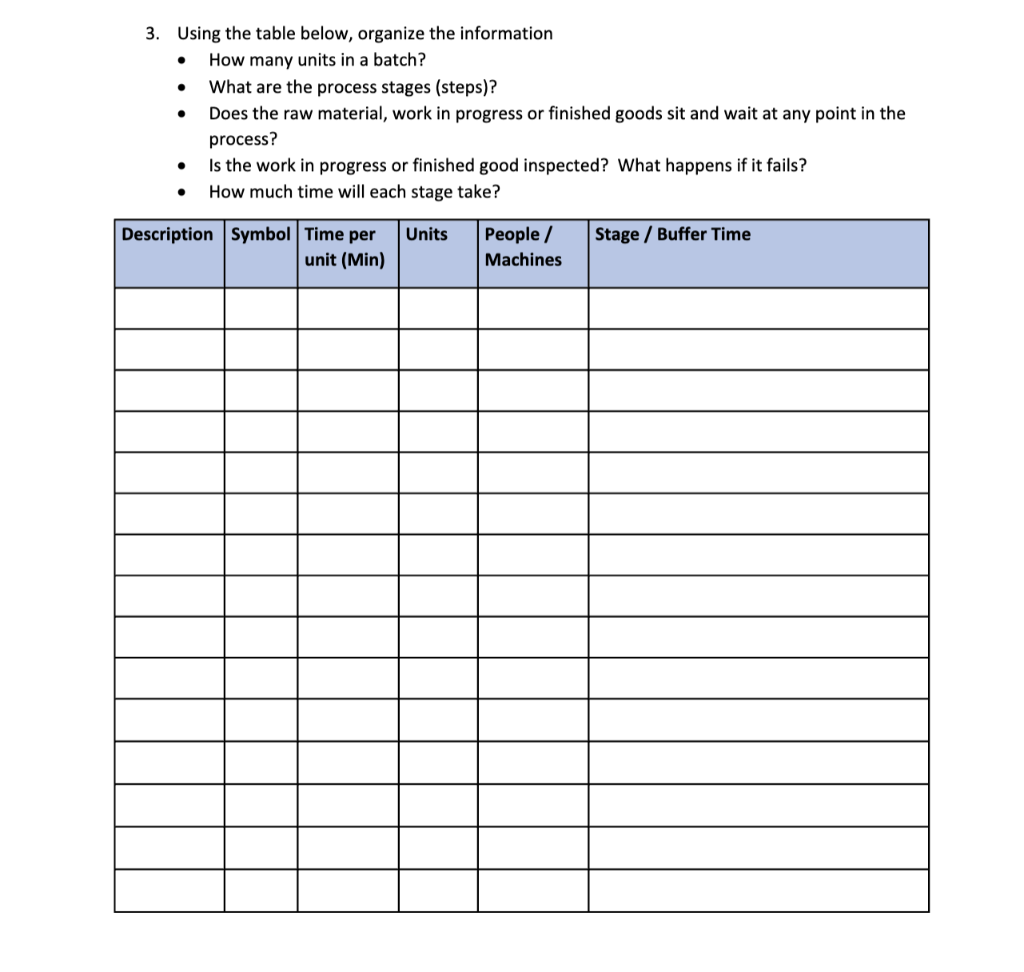

AMI Widget Manufacturing Process Materials are purchased in advance and kept in storage. A Material Handler (MH) removes sufficient materials from storage to create a batch of 70 widgets. They arrange the materials on the cart with an Operations and Routing Sheet. They move the cart to the "Cut" shop. The materials will remain on the cart until the Cut operator is ready to start. The average wait is 20 minutes. The Cut operator removes boards from the cart and cuts the boards into two sizes (Board A and Board B). The Cut operator places the cut boards back on the cart. It takes the Cut operators 20 minutes to cut all the boards and return them to the cart. Then the Cut operator moves the cart from "Cut" to "Drill". The work in progress (WIP) will remain on the cart until the Drill operators are ready to start. The average wait time is 30 minutes. There are two Drill operators and two drills. One Drill operator drills holes into Board A and the other Drill operator drills holes into Board B. It takes 30 seconds to remove each board from the cart, drill holes, and place finished board onto cart. When done, one of the Drill operators moves the cart from "Drill" to "Assemble". The WIP will remain on the cart until the Assemblers are ready to start. The average wait time is 15 minutes. There are five Assemblers. Each assembler assembles 1/5th of the Widgets. The Assembler removes materials and components to assemble their Widgets from the cart and arranges them on their workspace. This takes about 5 minutes (set-up time). They assemble widgets one at a time. It takes each Assembler 2 minutes to assemble a Widget and place the Widget on a paint rack. Once all are widgets are assembled, an Inspector inspects every widget on the paint rack. It takes about 10 seconds per widget to inspect. If the widget fails inspection it is removed from the rack and placed in a recycle bin. The widgets that pass inspection remain on the rack. On average 10 widgets fail inspection. Once all widgets are inspected, the Inspector moves the paint cart to "Paint." The work in progress (WIP) will remain on the paint rack until the Painter is ready to start. The average wait time for paint is 60 minutes. The Painter places the entire rack in the paint booth. It takes 12 minutes to paint the entire batch. Then the Painter moves the rack directly to the oven to bake for 120 minutes. Once dry, a MH moves the paint rack to "Quality Control". The Inspector begins inspecting the finished widgets as soon as the cart arrives. The Inspector removes the Widgets one by one from the paint rack and visually inspects the Widget for flaws. If the Widget passes inspection the Inspector places the Widget on a cart. If the Widget fails, the Inspector places the Widget in a recycle bin. It takes 1 minute per Widget to complete the inspection. On average 10 widgets fail inspection. The Inspector moves the cart of Widgets to "Package." There is one packager. The Packager begins packaging as soon as the cart arrives. The packager can package five Widgets every three minutes. 3. Using the table below, organize the information - How many units in a batch? - What are the process stages (steps)? - Does the raw material, work in progress or finished goods sit and wait at any point in the process? - Is the work in progress or finished good inspected? What happens if it fails? - How much time will each stage take? AMI Widget Manufacturing Process Materials are purchased in advance and kept in storage. A Material Handler (MH) removes sufficient materials from storage to create a batch of 70 widgets. They arrange the materials on the cart with an Operations and Routing Sheet. They move the cart to the "Cut" shop. The materials will remain on the cart until the Cut operator is ready to start. The average wait is 20 minutes. The Cut operator removes boards from the cart and cuts the boards into two sizes (Board A and Board B). The Cut operator places the cut boards back on the cart. It takes the Cut operators 20 minutes to cut all the boards and return them to the cart. Then the Cut operator moves the cart from "Cut" to "Drill". The work in progress (WIP) will remain on the cart until the Drill operators are ready to start. The average wait time is 30 minutes. There are two Drill operators and two drills. One Drill operator drills holes into Board A and the other Drill operator drills holes into Board B. It takes 30 seconds to remove each board from the cart, drill holes, and place finished board onto cart. When done, one of the Drill operators moves the cart from "Drill" to "Assemble". The WIP will remain on the cart until the Assemblers are ready to start. The average wait time is 15 minutes. There are five Assemblers. Each assembler assembles 1/5th of the Widgets. The Assembler removes materials and components to assemble their Widgets from the cart and arranges them on their workspace. This takes about 5 minutes (set-up time). They assemble widgets one at a time. It takes each Assembler 2 minutes to assemble a Widget and place the Widget on a paint rack. Once all are widgets are assembled, an Inspector inspects every widget on the paint rack. It takes about 10 seconds per widget to inspect. If the widget fails inspection it is removed from the rack and placed in a recycle bin. The widgets that pass inspection remain on the rack. On average 10 widgets fail inspection. Once all widgets are inspected, the Inspector moves the paint cart to "Paint." The work in progress (WIP) will remain on the paint rack until the Painter is ready to start. The average wait time for paint is 60 minutes. The Painter places the entire rack in the paint booth. It takes 12 minutes to paint the entire batch. Then the Painter moves the rack directly to the oven to bake for 120 minutes. Once dry, a MH moves the paint rack to "Quality Control". The Inspector begins inspecting the finished widgets as soon as the cart arrives. The Inspector removes the Widgets one by one from the paint rack and visually inspects the Widget for flaws. If the Widget passes inspection the Inspector places the Widget on a cart. If the Widget fails, the Inspector places the Widget in a recycle bin. It takes 1 minute per Widget to complete the inspection. On average 10 widgets fail inspection. The Inspector moves the cart of Widgets to "Package." There is one packager. The Packager begins packaging as soon as the cart arrives. The packager can package five Widgets every three minutes. 3. Using the table below, organize the information - How many units in a batch? - What are the process stages (steps)? - Does the raw material, work in progress or finished goods sit and wait at any point in the process? - Is the work in progress or finished good inspected? What happens if it fails? - How much time will each stage take

please fill in the chart

please fill in the chart